The lifting eye nuts should be made of 20 or 25 steel (GB699). The lifting eye nuts must be integrally forged, and the forging should be normalized and free of oxide skin. The grain size of the finished product should not be lower than level 5 (YB27-77), and the forging should not have overburning or crack defects.

Surface treatment of lifting eye nuts

Generally, surface treatment is not required for lifting eye nuts, but according to requirements, surface treatments such as galvanizing, passivation, and chromium plating can be carried out, and they should comply with the provisions of GB5267-85.

After electrogalvanizing, the chemical composition and mechanical properties of the material should be immediately subjected to oxygen removal treatment according to the test method specified in GB699. During routine inspection, the grain size test may not be advanced, and the testing method for grain size shall be in accordance with the provisions of YB27. Thread inspection is carried out using thread gauges and smooth limit gauges or universal gauges.

Precautions for the use of hanging mother and lifting ring

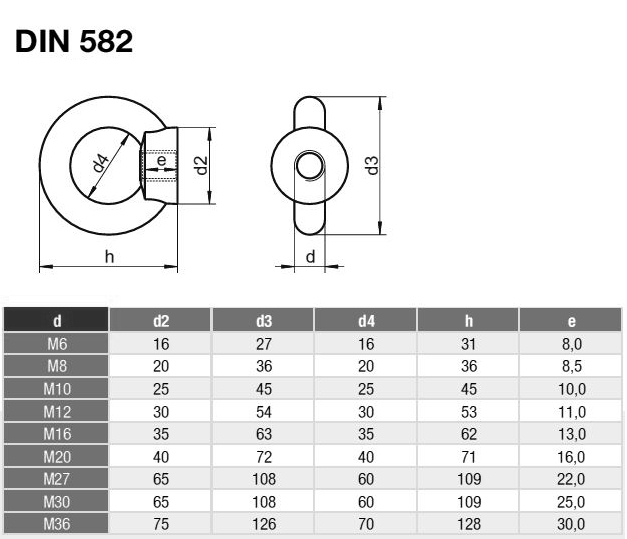

1. To prevent accidents, the usage load specified in the following figure must not be exceeded during use.

2. When there is visible deformation of the ring, it should be scrapped.

3. When lifting, accompanied by an increase in acceleration or impact, it is necessary to choose a load smaller than the one used in the table above.

4. When lifting at 45 °, measures such as spot facing should be added to ensure that the supporting surface of the bolt or nut is closely attached to the mating part. Secondly, add appropriate washers so that the directions of the two rings are in the same plane. The error (deflection) of this combination should be within 5 degrees from the plane containing the axis.

5. For the purpose of increasing mechanical properties, using materials such as special steel and undergoing heat treatment can reduce ductility and easily cause fracture before overload and ring deformation, which is dangerous.