News

Dec . 19, 2024 20:55 Back to list

custom rigging ship manufacturer

Custom Rigging Ship Manufacturer Crafting the Future of Maritime Engineering

In the world of maritime engineering, the demand for customized solutions has surged significantly due to evolving industry needs and technological advancements. One of the most integral aspects of ship manufacturing is rigging, which plays a crucial role in ensuring the safety, efficiency, and performance of vessels. Custom rigging ship manufacturers have emerged as key players in this field, specializing in bespoke solutions tailored to meet the unique requirements of their clients. This article explores the significance, processes, and innovations associated with custom rigging ship manufacturers.

The Significance of Custom Rigging

Rigging is the system of ropes, cables, or chains employed to support and control the sails and masts of a ship. Its design and fabrication directly influence a ship's maneuverability, stability, and strength. As maritime industries expand and diversify, custom rigging solutions have become essential for various vessel types, from commercial cargo ships to luxury yachts.

Custom rigging manufacturers are adept at understanding the specific needs of their clients, considering factors such as vessel size, purpose, and operating conditions. This level of customization not only enhances the overall performance of the ships but also provides safety assurances in the often unpredictable marine environment.

The Manufacturing Process

The journey of creating custom rigging begins with thorough consultations between the manufacturer and the client. These discussions focus on the intended use of the vessel and the specific challenges it may face at sea. Once requirements are established, the manufacturer moves toward design and engineering, utilizing cutting-edge software and techniques to create precise specifications.

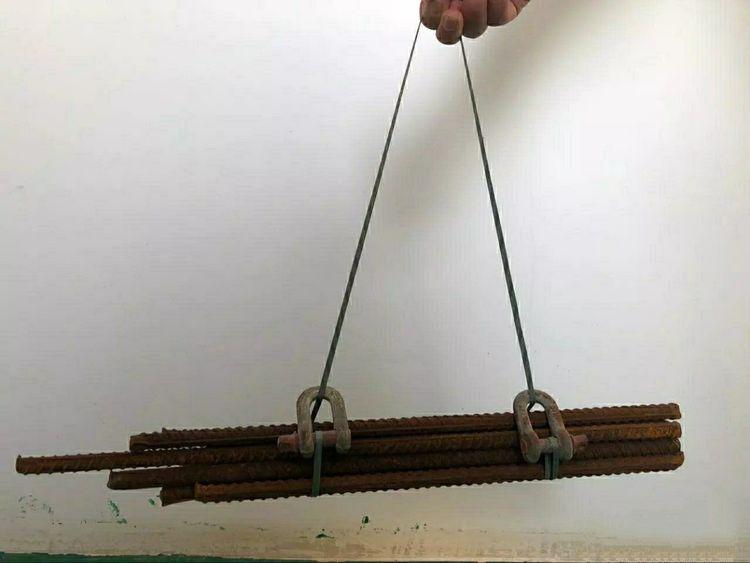

Advanced materials are an integral part of custom rigging. Manufacturers often employ high-strength synthetic fibers, stainless steel, and carbon composites to ensure durability while maintaining a lightweight profile. The choice of materials is critical, as it affects the rigging's weight, strength, and resistance to corrosive marine environments.

custom rigging ship manufacturer

After finalizing designs and selecting materials, the fabrication process commences. This phase may involve cutting, weaving, integrating hardware components, and rigorous testing. Quality control is paramount; custom rigging undergoes strict inspections to ensure that it meets safety standards and performance expectations before it is shipped to the client.

Innovations in Custom Rigging

The maritime industry is witnessing revolutionary advancements in rigging technology, changing the way manufacturers approach custom solutions. One notable trend is the integration of smart technologies. Manufacturers are increasingly incorporating sensors and monitoring systems into rigging designs, allowing real-time data collection on strain, tension, and overall performance. This data enables ship operators to make informed decisions regarding maintenance and operational efficiency.

Additionally, the rise of automation in manufacturing processes has allowed custom rigging ship manufacturers to enhance precision and reduce lead times. Advanced machinery can now produce highly intricate rigging components with minimal human intervention, leading to increased efficiency and decreased costs.

Environmental considerations are also shaping the innovations in the industry. Manufacturers are exploring eco-friendly materials and sustainable practices in the production of custom rigging. This commitment to sustainability resonates with an industry increasingly focused on reducing its ecological footprint.

Conclusion

Custom rigging ship manufacturers are at the forefront of transforming maritime engineering through innovative, tailored solutions. Their expertise not only ensures that vessels are equipped to handle the challenges of the sea but also contributes to the growth of a more sustainable and efficient maritime industry. As technology and materials continue to evolve, the future of custom rigging looks promising, paving the way for safer, more efficient, and environmentally responsible maritime operations. Whether for commercial shipping or recreational boating, the role of custom rigging will remain integral in defining the success of modern vessels.