News

دسمبر . 05, 2024 15:42 Back to list

large heavy duty turnbuckles china

Understanding Large Heavy Duty Turnbuckles from China A Comprehensive Overview

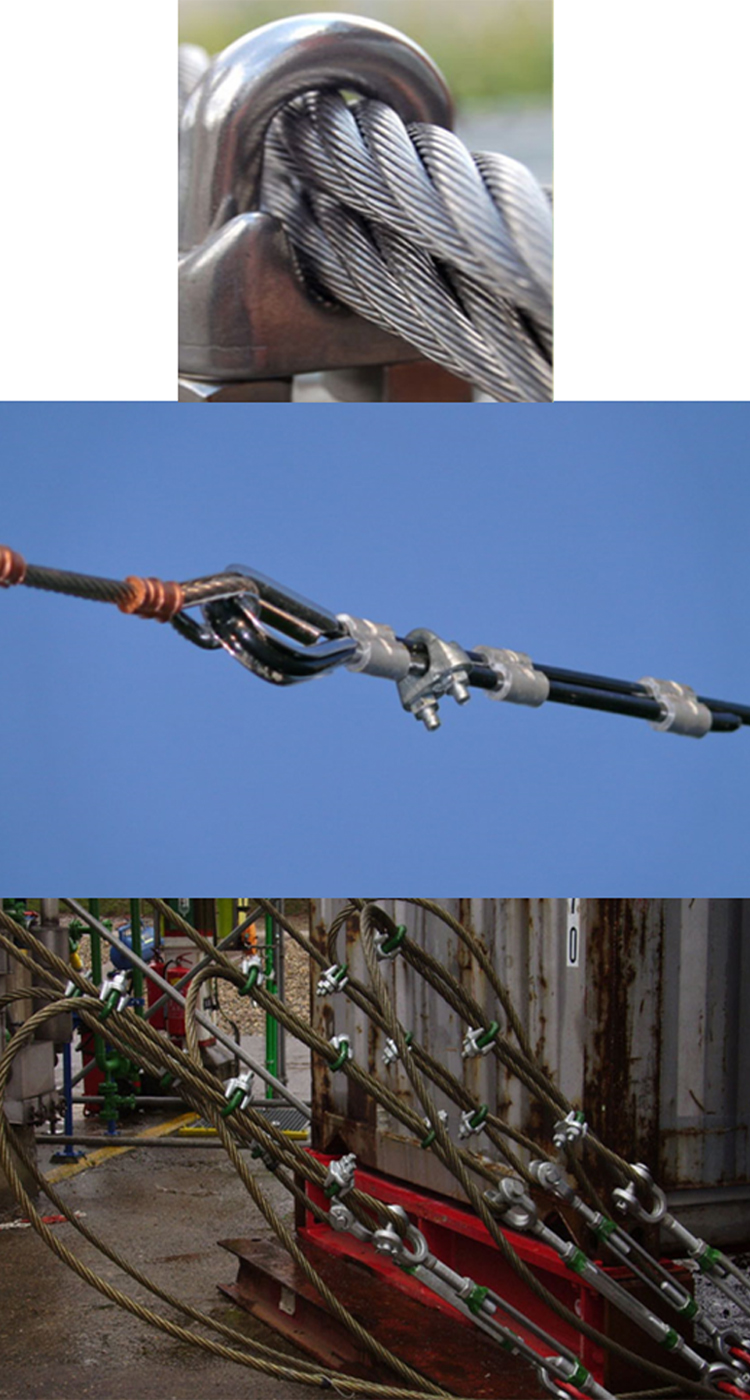

In various industries, the importance of reliable fastening and tensioning equipment cannot be understated. Among these essential tools, large heavy-duty turnbuckles play a crucial role. Known for their strength, durability, and versatility, turnbuckles are used to adjust the tension of cables, ropes, and other rigging systems. This article delves into the intricacies of large heavy-duty turnbuckles manufactured in China, exploring their features, applications, production processes, and market trends.

Features of Large Heavy Duty Turnbuckles

Large heavy-duty turnbuckles are typically constructed from high-strength materials such as stainless steel, carbon steel, or even aluminum, depending on the specific requirements of the application. Their design includes a threaded body with two eye or hook ends, allowing for easy connection to other hardware components. The mechanism works by turning the central body, which then adjusts the distance between the two ends, thereby increasing or decreasing tension.

One of the most notable features of these turnbuckles is their ability to withstand significant loads while maintaining structural integrity. They are engineered to carry heavy loads in environments ranging from maritime applications to construction sites. In addition, many manufacturers in China incorporate anti-corrosive coatings and treatments to enhance the longevity of the turnbuckles, especially in harsh weather conditions or marine environments.

Applications of Large Heavy Duty Turnbuckles

The applications for large heavy-duty turnbuckles are vast and varied. In the construction industry, they are used for tensioning cables in structural frameworks, securing scaffolding systems, and stabilizing large structures during the building process. Their strength makes them ideal for holding together components that are subject to substantial environmental forces.

In marine applications, turnbuckles provide a secure means of tensioning rigging for sailboats and yachts. They are essential in maintaining the correct tension in the rigging, which is crucial for both safety and performance. Additionally, heavy-duty turnbuckles are used in the automotive and aerospace industries for securing parts and ensuring optimal performance under high-stress conditions.

Production Processes in China

China is a global leader in manufacturing, with a well-developed infrastructure for producing heavy-duty hardware, including turnbuckles

. The production process typically involves several stageslarge heavy duty turnbuckles china

1. Material Selection High-quality raw materials are sourced, with a focus on strength and durability.

2. Machining Advanced CNC (Computer Numerical Control) machines are employed to create precise components. This ensures that each turnbuckle meets strict specifications.

3. Finishing Treatments After machining, components undergo various finishing processes, such as galvanizing or powder coating, to improve corrosion resistance and aesthetic appeal.

4. Assembly The final assembly process aligns all components correctly to ensure proper functionality.

5. Quality Control Finally, strict quality control measures are implemented to test the turnbuckles for load-bearing capacity, durability, and compliance with international standards.

Market Trends and Demand

The global demand for large heavy-duty turnbuckles is on the rise, driven by increased construction activities, infrastructure development, and maritime operations. China, as a leading manufacturer, continuously adapts to market trends by improving production techniques and offering a variety of customized solutions to meet diverse customer needs.

Additionally, the export market for turnbuckles is thriving, with international buyers seeking high-quality Chinese products that provide excellent value for money. As industries evolve and new demands emerge, the manufacturing capabilities and innovations in China's turnbuckle production are expected to keep pace, ensuring that they remain a top choice for heavy-duty fastening solutions.

Conclusion

In summary, large heavy-duty turnbuckles from China represent a cornerstone of reliable fastening solutions across multiple industries. With their robust design, diverse applications, and cutting-edge manufacturing processes, these turnbuckles continue to play a vital role in enhancing safety and effectiveness in numerous projects. As global demand grows, China’s commitment to quality and innovation positions them as a key player in the market, ensuring that heavy-duty turnbuckles remain accessible and effective for various applications around the world.