News

Гру . 12, 2024 07:29 Back to list

Custom Turnbuckle Solutions for Specialized Supply Needs in Various Industries

The Importance of Custom Turnbuckles Supply in Modern Engineering

Turnbuckles are essential components in a variety of engineering and construction applications, serving as critical hardware in the tensioning and securing of cables, ropes, and rods. The unique aspect of custom turnbuckles supply lies in the ability to tailor these devices to meet specific requirements, ensuring optimal performance across diverse industries.

Understanding Turnbuckles

A turnbuckle is a mechanical device that consists of two threaded eye bolts, with a central body that can be rotated to adjust the tension in the cables or rods to which it is attached. This simple yet effective mechanism allows for precise adjustments, making it invaluable in applications ranging from rigging and scaffolding to construction and aerospace industries.

The Role of Customization

Customization plays a pivotal role in the functionality of turnbuckles. Off-the-shelf products may not always meet the exact specifications required for particular applications. Custom turnbuckles can be designed for unique dimensions, materials, and performance characteristics, enabling engineers to ensure safety and efficiency in their projects.

1. Materials Different applications demand different materials. For instance, marine environments require corrosion-resistant materials such as stainless steel or specialized alloys, while industries involving high temperatures might require heat-resistant materials. By providing custom solutions, suppliers can meet specific material needs.

2. Size and Dimensions Projects can vary significantly in scale. A large construction site may need heavy-duty turnbuckles capable of handling substantial loads, while smaller projects may require lightweight options. Custom turnbuckles can be manufactured in various sizes to accommodate these specific requirements.

3. Load Capacity Turnbuckles must be able to withstand specific load ratings depending on their applications. Customized solutions can take into account the anticipated loads, ensuring safety and stability in engineering designs.

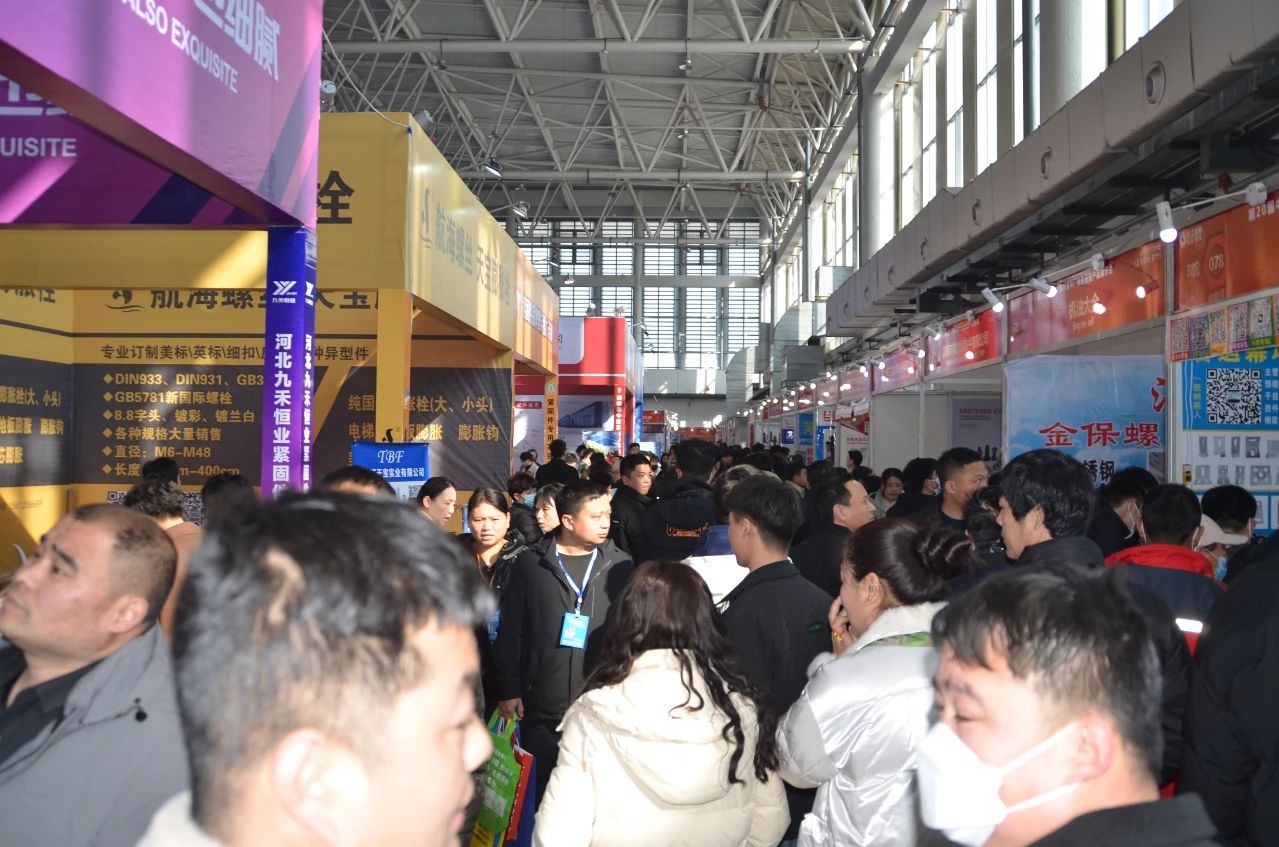

custom turnbuckles supply

4. Design and Aesthetics Sometimes, the design of the turnbuckle is just as important as its functional capabilities. Custom designs can enhance the visual appeal of a completed project or be constructed to integrate seamlessly with existing systems.

Benefits of Using Custom Turnbuckles

1. Enhanced Performance Custom turnbuckles are engineered to meet specific project demands, resulting in superior performance. Adjustability and tailored specifications help maintain the integrity of the structure or system in which they are used.

2. Increased Safety In engineering and construction, safety is paramount. By using custom turnbuckles designed for specific loads and conditions, accidents and failures can be significantly minimized. Tailored products undergo thorough safety testing and adhere to industry standards.

3. Cost-Effectiveness While custom solutions might initially seem more expensive than generic alternatives, they can provide long-term savings by reducing maintenance costs and improving longevity. Well-designed turnbuckles can lead to fewer replacements and greater reliability in systems.

4. Rapid Turnaround Many suppliers of custom turnbuckles have streamlined their manufacturing processes, allowing for quick turnaround times. This efficiency means that engineers and construction managers can obtain the necessary components without significant delays, keeping projects on schedule.

Selecting a Reliable Supplier

Choosing the right supplier for custom turnbuckles is crucial. Companies should look for suppliers with a proven track record in the industry, positive customer reviews, and an ability to provide technical support. Additionally, suppliers that offer advanced manufacturing capabilities, such as CNC machining, can ensure precision and quality in their products.

In conclusion, the importance of custom turnbuckles supply cannot be overstated in the realm of modern engineering. Their ability to meet specific requirements across various industries makes them indispensable in ensuring safety and efficiency. As projects become increasingly complex, the need for tailored solutions will only grow. Engineers and project managers must prioritize collaboration with reliable suppliers to harness the full potential of custom turnbuckles, paving the way for successful and innovative engineering endeavors.