Haberler

Eki . 16, 2025 15:48 Listeye geri dön

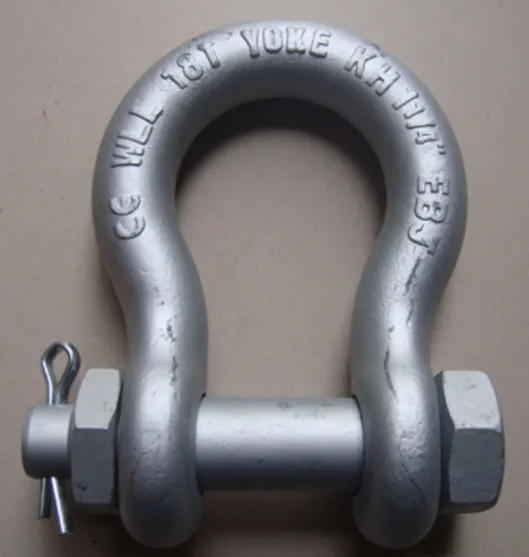

Shackles: carry critical connections and define safety standards

Shackle is a metal connector used to connect steel wire ropes, lifting belts, chains, or other rigging. It is one of the most basic and commonly used rigging connectors in fields such as lifting and hoisting, ship operations, engineering construction, power line installation, and logistics transportation

Its core function is to provide a quick detachable, high-strength connecting ring between the lifting point and the lifted object or different rigging.

There are various ways to classify shackles, mainly including the following:

1. Classify by shape (this is the most commonly used classification method)

·D-type shackle:

·Characteristic: The bow shaped part (curved ring) is semi-circular, forming a "D" shape together with the straight edge where the pin shaft is located.

·Advantages: The bow shaped part has high strength, the weight is concentrated on one side of the pin shaft, and it is not easy to rotate when subjected to force, making it the most commonly used type.

·Application: Strong universality, suitable for most lifting occasions.

Bow shaped shackle (also known as Omega shaped or U-shaped shackle):

·Characteristic: The entire bow shaped part is a symmetrical U-shape.

·Advantages: The interior space is wider and can accommodate thicker ropes or multi strand rigging.

·Application: Commonly used for connecting wider lifting straps or in situations where a larger contact area is required.

Bolt type shackle:

·Features: One end of the pin shaft has threads, and the other end has a hole for inserting an open-ended pin or safety pin to secure it.

·Advantages: Extremely high safety, the pin shaft will not accidentally rotate out, making it the first choice for heavy loads and critical lifting.

·Disadvantage: Installation and disassembly are the most complicated, requiring tools and split pins.

Classified by manufacturing method

·Forging Shackles: Made by high-temperature forging of molds, with continuous fiber structure, high strength, and good toughness, it is the mainstream manufacturing process for high-quality Shackles.

·Casting Shackles: Casting molten metal into a mold to shape it. There may be internal defects such as pores and sand holes, and the strength and toughness are usually not as good as forging. Generally not used in critical safety situations such as lifting.

Always let the force act on the body of the shackle, not on the pin shaft! That is, 'pull the bow without pulling the pin'.

·Avoid lateral forces, bending forces, and leverage effects, which can significantly reduce the load-bearing capacity of the shackle.

Although the shackle is small, it is a crucial part of lifting safety. Professional understanding of its type, grade, and correct usage methods, as well as strict adherence to inspection and scrapping standards, is fundamental to preventing accidents and ensuring the safety of personnel and equipment. Always remember that the safety factor is built on the correct selection and use.

-

Small components of lifting ring nuts with large load-bearing capacity

HaberlerNov.24,2025

-

Flower basket bolts inject stable strength into your project

HaberlerNov.18,2025

-

Although the lifting ring is small, its function is enormous

HaberlerNov.12,2025

-

Lifting shackle: The indispensable "safety connecting ring" in lifting operations

HaberlerNov.05,2025

-

Full analysis of lifting chain technology and application standards

HaberlerOct.31,2025

-

Card head usage guide

HaberlerOct.28,2025