News

Oca . 20, 2025 01:05 Back to list

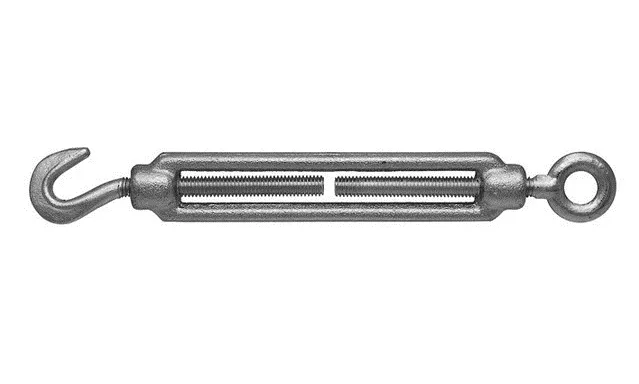

china rigging hook types

China has long been a dominant player in the manufacturing and exportation of rigging equipment, with rigging hooks being one of the most crucial components in a wide range of industries, from construction to marine activities. Understanding the different types of rigging hooks available can vastly improve operational efficiency and safety. This guide aims to explore the varieties of China-manufactured rigging hooks and how selecting the right type can enhance workplace efficacy while ensuring compliance with international safety standards.

Swivel Hooks come with a swiveling mechanism that allows rotation under load conditions, preventing the entanglement of lifting lines. Especially useful in shipping yards and construction sites where load alignment is critical, China's state-of-the-art production technologies result in swivel hooks that offer unparalleled performance and flexibility. Foundry Hooks are designed explicitly for the rigors of material handling in foundries. Their design accommodates larger openings, making them suitable for handling bulky or challenging materials. Chinese innovation in hook casting and finishing processes has led to foundry hooks that provide exceptional wear resistance and load capacity. Self-Locking Hooks feature a mechanism that automatically locks the hook when a load is applied, significantly enhancing safety by preventing accidental opening. Used in high-security operations such as offshore and aerospace, Chinese manufacturers have adopted cutting-edge engineering practices to produce self-locking hooks that adhere to stringent global safety protocols. The China's rigging hook industry is synonymous with quality and innovation, continuously pushing the envelope with new developments in material science and production techniques. The trustworthiness of Chinese rigging hooks is reflected in their widespread approval and certification by international safety standards such as the Occupational Safety and Health Administration (OSHA) and the European Union’s CE marking. Choosing the right type of rigging hook can dramatically affect operational efficacy and safety metrics. It's crucial to assess factors such as load requirements, environmental conditions, and usage frequency when selecting rigging hooks. Investing in high-quality products from esteemed Chinese manufacturers not only guarantees compliance with safety norms but also leads to a long-term reduction in operational costs due to decreased equipment failure and maintenance issues. In conclusion, China's diverse array of rigging hook types serves various industries by meeting high performance and reliability standards. The decision to use Chinese rigging hooks should be informed by their proven track record of expertise and their commitment to delivering secure and durable rigging solutions.

Swivel Hooks come with a swiveling mechanism that allows rotation under load conditions, preventing the entanglement of lifting lines. Especially useful in shipping yards and construction sites where load alignment is critical, China's state-of-the-art production technologies result in swivel hooks that offer unparalleled performance and flexibility. Foundry Hooks are designed explicitly for the rigors of material handling in foundries. Their design accommodates larger openings, making them suitable for handling bulky or challenging materials. Chinese innovation in hook casting and finishing processes has led to foundry hooks that provide exceptional wear resistance and load capacity. Self-Locking Hooks feature a mechanism that automatically locks the hook when a load is applied, significantly enhancing safety by preventing accidental opening. Used in high-security operations such as offshore and aerospace, Chinese manufacturers have adopted cutting-edge engineering practices to produce self-locking hooks that adhere to stringent global safety protocols. The China's rigging hook industry is synonymous with quality and innovation, continuously pushing the envelope with new developments in material science and production techniques. The trustworthiness of Chinese rigging hooks is reflected in their widespread approval and certification by international safety standards such as the Occupational Safety and Health Administration (OSHA) and the European Union’s CE marking. Choosing the right type of rigging hook can dramatically affect operational efficacy and safety metrics. It's crucial to assess factors such as load requirements, environmental conditions, and usage frequency when selecting rigging hooks. Investing in high-quality products from esteemed Chinese manufacturers not only guarantees compliance with safety norms but also leads to a long-term reduction in operational costs due to decreased equipment failure and maintenance issues. In conclusion, China's diverse array of rigging hook types serves various industries by meeting high performance and reliability standards. The decision to use Chinese rigging hooks should be informed by their proven track record of expertise and their commitment to delivering secure and durable rigging solutions.

Share

Next: