News

Kas . 25, 2024 01:57 Back to list

Exploring the Production Processes of Ambull Shackles in Modern Factories

The Impact of Ambull Shackles Factories on Modern Manufacturing

In the evolving landscape of modern manufacturing, the role of specialty components is becoming increasingly significant. One area that has garnered attention is the production of ambull shackles. These specialized fixtures are crucial in various industrial applications, including construction, shipping, and military use. Understanding the intricacies of ambull shackles factories can provide insights into the broader manufacturing processes, technological advancements, and socio-economic implications inherent in this niche industry.

What are Ambull Shackles?

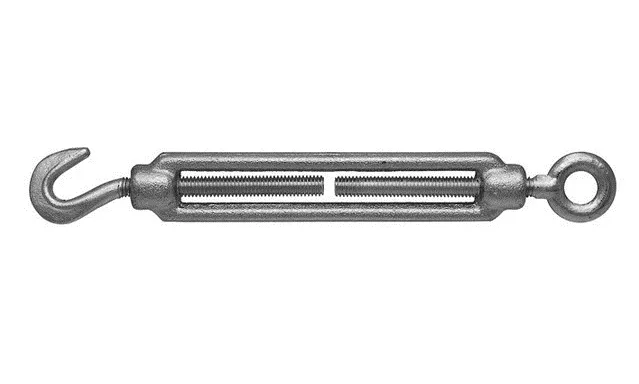

Ambull shackles, often referred to as anchor shackles, are robust fastening devices used to connect components securely. They are commonly made from high-strength materials such as stainless steel or carbon steel, engineered to withstand heavy loads and harsh conditions. These shackles come in various sizes and designs to accommodate different applications, making them versatile tools for engineers and manufacturers. The demand for these shackles is driven by their reliability and safety features, particularly in environments where failure is not an option.

The Production Process

The manufacturing of ambull shackles involves several key processes, each of which contributes to the final product's strength and durability. It begins with the selection of raw materials. Factories need to source high-quality metals that meet industry standards for strength and corrosion resistance. Following material selection, the manufacturing process typically involves several stages

1. Cutting and Shaping Raw metal is cut into desired shapes and sizes using precision machinery. 2. Forging The cut pieces are then subjected to high temperatures and force to form their final shapes. This process enhances the material's structural integrity. 3. Machining Further machining is conducted to achieve specific dimensions and tolerances necessary for the shackles to function correctly. 4. Finishing Finally, finishing processes such as polishing and coating are applied to enhance appearance and add protective layers against corrosion.

The rigorous manufacturing process ensures that ambull shackles meet stringent quality standards, a factor that is non-negotiable in industries where safety is paramount.

Technological Advancements

ambull shackles factories

The landscape of ambull shackles manufacturing is not static; it is continually evolving with advancements in technology. Automation plays a crucial role in improving efficiency and reducing the likelihood of human error during production. Various factories are implementing robotics and computer numerical control (CNC) machines to streamline processes and enhance precision.

Moreover, the adoption of 3D printing technology is reshaping the industry by offering rapid prototyping capabilities. Manufacturers can now create prototypes of shackles to test their designs before mass production, significantly shortening the development time of new models.

Equally important is the integration of digital tools such as Computer-Aided Design (CAD) software, which allows engineers to visualize and optimize designs without the need for physical prototypes. This innovative approach not only accelerates the design phase but also minimizes material waste, reflecting an increasing industry trend towards sustainability.

Economic and Social Implications

The presence of ambull shackles factories impacts local economies by creating jobs and stimulating related industries, such as raw material supply and logistics. As ambull shackles find applications in global markets, these factories contribute to export revenue, enhancing economic growth.

Socially, the manufacturing of ambull shackles plays a vital role in ensuring safety in various sectors. By providing reliable fastening solutions, these factories indirectly contribute to the protection of workers and consumers alike. Industries such as construction and marine engineering depend heavily on the durability and reliability of shackles to ensure that heavy loads and equipment are safely managed.

Conclusion

In conclusion, ambull shackles factories represent a small yet critical segment of the broader manufacturing industry. Through advanced production processes, technological innovations, and significant economic contributions, these factories play an essential role in modern industrial applications. As the demand for high-quality, reliable components continues to grow, understanding the dynamics of ambull shackles manufacturing becomes increasingly important. The future of this industry holds promise, with technological advancements propelling it into new realms of efficiency, sustainability, and reliability.