News

Sep . 14, 2024 03:25 Back to list

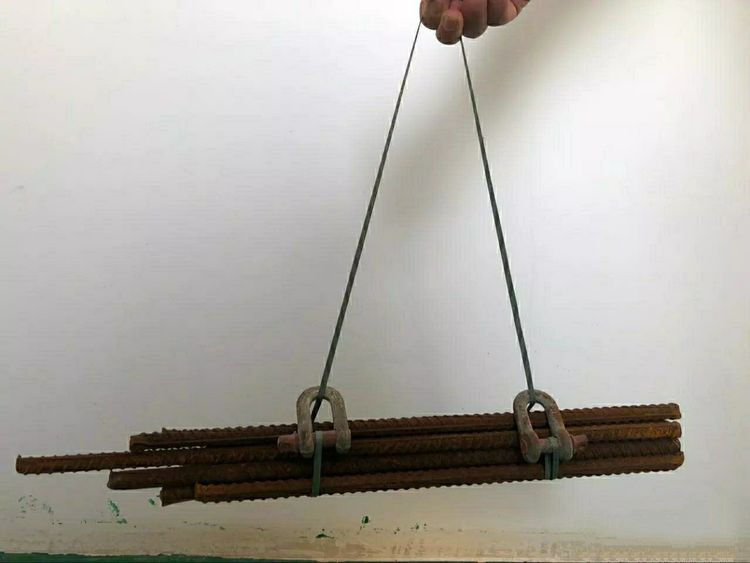

odm hardware rigging products

Exploring ODM Hardware Rigging Products A Comprehensive Overview

In today's rapidly evolving technological landscape, the demand for high-quality hardware rigging products has surged across various industries, including entertainment, construction, and event management. Original Design Manufacturers (ODMs) play a critical role in this sector, creating innovative and reliable solutions tailored to the specific needs of their clients. This article delves into the significance of ODM hardware rigging products and their impact on different applications.

Understanding ODM Hardware Rigging Products

ODM hardware rigging products encompass a wide range of equipment designed to support and secure various structures and load-bearing applications. These products include but are not limited to trusses, hoists, clamps, and other rigging accessories. The essence of ODM manufacturing lies in its ability to provide custom solutions that meet rigorous industry standards while offering clients flexibility and scalability.

One of the standout features of ODM products is their design capabilities. By working closely with clients, ODMs can develop products that incorporate specific functionalities, materials, and aesthetic preferences. This personalized approach not only enhances performance but also ensures that the end products align with the client's vision and requirements.

Applications of ODM Hardware Rigging Products

ODM hardware rigging products are utilized in diverse fields, such as live event production, theatrical performances, film and television production, and architectural construction. In the entertainment industry, for instance, the ability to create intricate lighting setups and secure audio-visual equipment is vital for achieving the desired atmosphere and effect. ODM rigging products offer durability and reliability, essential traits when dealing with heavy loads and complex setups.

odm hardware rigging products

In construction, these products ensure that the necessary frameworks are in place to support various structures, from temporary stages to permanent installations. The safety and efficiency of construction projects heavily depend on the quality of rigging equipment used, making ODM solutions critical for successful project execution.

Benefits of Choosing ODM Products

The advantages of partnering with ODMs for hardware rigging solutions are manifold. Firstly, ODMs can significantly reduce time-to-market for new products. By utilizing their established manufacturing processes and expertise, clients can bring innovations to life more rapidly than if they were to develop the products in-house.

Furthermore, ODMs often have access to advanced technologies and materials, enabling them to produce high-quality products that may otherwise be challenging to obtain. This access not only enhances product reliability but also allows for the incorporation of the latest industry innovations.

Cost-effectiveness is another substantial benefit. By outsourcing the design and manufacturing process to an ODM, companies can often reduce overhead costs associated with research and development, prototyping, and production.

Conclusion

In conclusion, ODM hardware rigging products represent a vital segment of the industry, providing tailored solutions that cater to the unique requirements of various applications. As industries continue to innovate and adapt, the role of ODMs in producing high-quality rigging products will become increasingly prominent. By choosing to partner with these manufacturers, companies can leverage their expertise, access cutting-edge technologies, and ultimately enhance the safety and efficiency of their projects. As we look ahead, the potential for growth in this field is immense, promising exciting advancements for both manufacturers and end-users alike.