News

Nov . 15, 2024 23:40 Back to list

wholesale types of rigging slings

Understanding Wholesale Types of Rigging Slings

In the world of industrial lifting and rigging, slings play a pivotal role in ensuring safety, efficiency, and effectiveness in moving heavy loads. Whether in construction, manufacturing, or shipping, selecting the appropriate type of rigging sling is crucial. Wholesale suppliers offer a variety of sling types, each designed for specific applications and load requirements. This article will explore the main types of rigging slings available in wholesale markets, highlighting their features and uses.

1. Wire Rope Slings

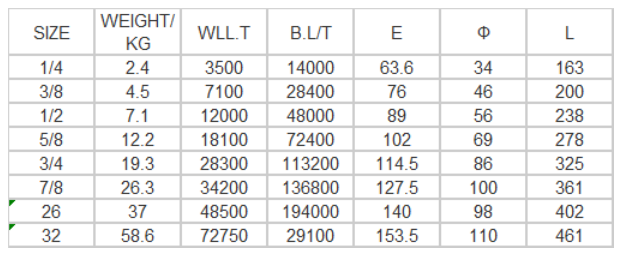

Wire rope slings are widely used in heavy lifting applications due to their strength and durability. Made from several strands of wire twisted together, these slings can withstand high temperatures and are resistant to abrasion and cutting. Wire rope slings are ideal for lifting heavy machinery and construction materials. Wholesale suppliers commonly provide them in various configurations, such as single-leg, double-leg, or multi-leg styles, allowing users to choose based on their specific lifting needs.

Synthetic slings, including nylon and polyester types, have gained popularity due to their lightweight and flexibility. They are less abrasive and do not damage the load as harshly as metal slings. Nihile slings usually feature a wider surface area, distributing the load evenly, which reduces the risk of damage. These slings are suitable for lifting delicate items and can be used in a variety of environments. Wholesale options include endless slings, flat webbing slings, and round slings, catering to different lifting techniques.

3. Chain Slings

wholesale types of rigging slings

Chain slings are another robust option for heavy lifting. Made from high-strength alloy steel, these slings can handle extreme loads and harsh conditions, making them ideal for industrial applications. Chain slings can be adjustable in length and configuration, providing flexibility in usage. They are particularly useful in environments involving high temperatures or corrosive substances. Wholesale suppliers usually offer chain slings with various grade ratings, ensuring users can select the right sling for their specific load requirements.

4. Combination Slings

Combination slings merge the strengths of different materials, often combining wire rope or chain with synthetic components. These versatile slings provide the benefits of both worlds, offering durability along with lightweight handling. They are suitable for various applications, including construction and cargo lifting. Wholesale availability of combination slings further enhances their usefulness, allowing companies to stock up on this adaptable lifting solution.

5. Specialty Slings

In addition to the standard types, numerous specialty slings are available for specific applications. These may include slings designed for lifting unique shapes, such as plates or tubes, and those equipped with protective sleeves or coatings to prevent damage to expensive loads. Wholesale suppliers typically offer custom options to meet specific industry needs.

In summary, the wholesale market for rigging slings provides an extensive variety of options, including wire rope, synthetic, chain, combination, and specialty slings. Each type serves specific purposes, ensuring that businesses can find the right sling for their lifting requirements. By understanding the features and applications of each type, companies can enhance safety and efficiency in their lifting operations. Proper selection, combined with the expertise of wholesale suppliers, can significantly contribute to the success of any lifting project.