News

Nov . 19, 2024 09:24 Back to list

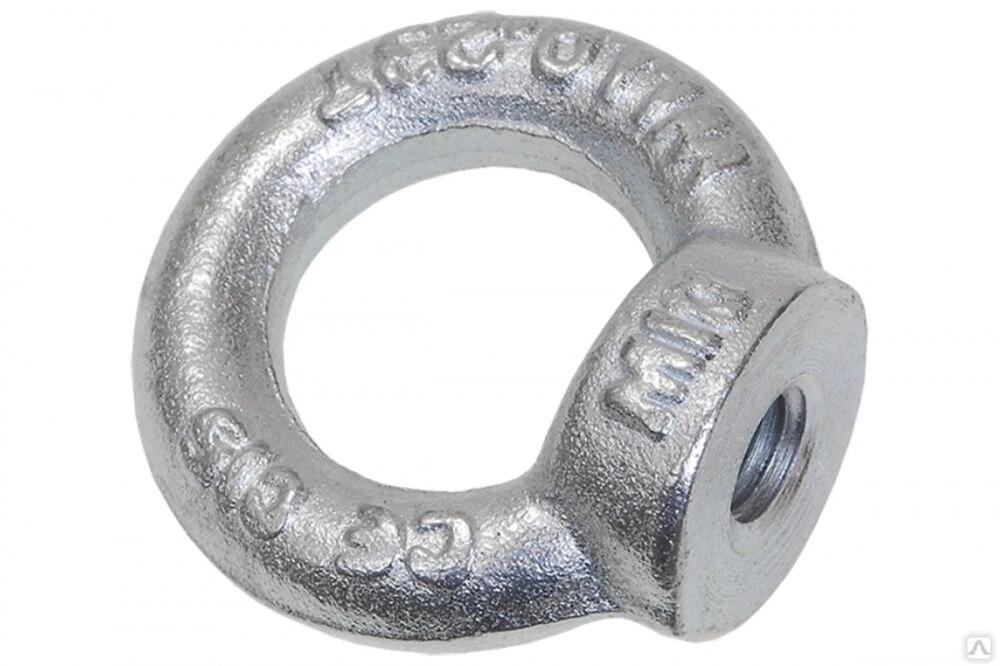

odm qualified rigger supplies

Understanding ODM Qualified Rigger Supplies

In the realm of construction and rigging, the safety and effectiveness of operations hinge significantly on the quality of equipment used. ODM (Original Design Manufacturer) qualified rigger supplies play a crucial role in ensuring that rigging tasks are performed to the highest standards. This article delves into the importance of ODM qualified rigger supplies, their benefits, and the key features that distinguish them from standard equipment.

First and foremost, ODM qualified rigger supplies are designed with precision and engineered to meet or exceed industry safety standards. These supplies encompass a range of equipment, including rigging hardware, lifting devices, and safety gear. What sets ODM products apart is that they are manufactured by companies specializing in the design and production of rigging equipment tailored to the specific needs of various applications. This specialized approach results in equipment that is not just functional but optimized for safety and efficiency.

Understanding ODM Qualified Rigger Supplies

Moreover, ODM rigger supplies often come with comprehensive certifications and compliance documentation. This is crucial for companies that operate in regulated industries, as it verifies the equipment meets specific safety and quality standards. When clients know that their rigging supplies are ODM qualified, it builds trust and assures them that safety is taken seriously. This level of certification can also enhance a company’s reputation, making it a preferred choice for contractors and clients looking for reliable rigging solutions.

odm qualified rigger supplies

In addition to safety, efficiency is another critical factor where ODM qualified rigger supplies make a difference. These products are designed not just for safety but also for optimal performance. For example, advanced rope and lifting systems can improve the speed and ease of rigging tasks, which translates to time savings and increased productivity on site. This efficiency is important not only for the bottom line but also for meeting project deadlines and keeping client satisfaction high.

Furthermore, ODM qualified rigger supplies often incorporate innovative technologies and materials that might not be found in standard equipment. For instance, the use of lightweight yet durable materials can reduce the physical strain on workers while improving handling during rigging operations. Innovations such as self-locking mechanisms and advanced load monitoring systems enhance usability and safety, ensuring that teams can focus on their tasks without constant worry about equipment failure.

Finally, engaging with ODM qualified suppliers fosters collaboration and support throughout the rigging process. Many ODM manufacturers offer additional services such as training, maintenance, and repair, which can be invaluable. They can provide expertise in selecting the right equipment for specific jobs and offer solutions tailored to unique challenges in rigging operations.

In conclusion, the importance of ODM qualified rigger supplies cannot be overstated. By prioritizing safety, efficiency, and innovation, these supplies enhance the rigging process, ensuring that projects are completed safely and efficiently. As industries evolve and demands grow, investing in high-quality, ODM qualified equipment will be essential for businesses looking to maintain their competitive edge and uphold the highest safety standards in the rigging sector.