News

Dec . 25, 2024 13:42 Back to list

bad rigging product

Understanding Bad Rigging Products Risks, Consequences, and Solutions

Rigging is a critical aspect of various industries, particularly in construction, maritime, and entertainment. It involves the use of equipment, such as ropes, chains, and slings, to lift, move, or secure loads safely. However, the presence of bad rigging products poses significant risks, potentially leading to accidents, injuries, and financial losses. This article will explore the various consequences of using substandard rigging products, identify key indicators of poor quality, and suggest solutions to mitigate the associated risks.

The Risks of Bad Rigging Products

The most immediate risk associated with bad rigging products is the potential for failure during lifting operations. A compromised sling or a defective hook can result in dropped loads, endangering workers and bystanders alike. This is particularly concerning in busy construction sites or during theatrical performances, where numerous people may be present under the load. The consequences can be tragic, leading to serious injuries or fatalities.

In addition to physical harm, the financial implications of using bad rigging products can be severe. Accidents can result in costly damages not only to equipment and materials but also to facilities and infrastructure. Insurance premiums may rise, and companies can face lawsuits from injured parties. Following an incident, the negative publicity can tarnish a business’s reputation, leading to a loss of clients and reduced profit margins.

Identifying Bad Rigging Products

It is crucial to identify bad rigging products before they cause harm. Here are several indicators to watch for

1. Lack of Certification Reliable rigging products should meet industry standards and be certified by established organizations. Products lacking certifications or that are from unknown manufacturers may not meet safety standards.

2. Visible Damage Signs of wear, corrosion, or deformation in rigging equipment are red flags. Inspect products regularly for any damage that could compromise their integrity.

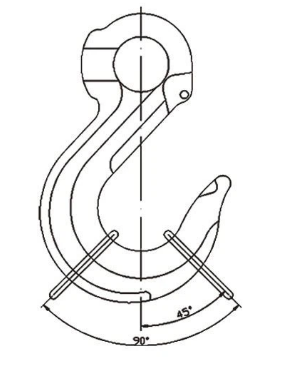

3. Poor Workmanship Products that exhibit poor craftsmanship, such as uneven stitching on slings or rough finishes on hooks, can be more prone to failure. Always purchase products from reputable suppliers who prioritize quality.

bad rigging product

4. Unusual Weight Capacity Ratings If a product seems too lightweight for its advertised lifting capacity, it could be a sign of a bad rigging product. Always verify specifications against industry standards.

Solutions to Mitigate Risks

To prevent the dangers associated with bad rigging products, stakeholders in industries that utilize rigging should take proactive measures

1. Regular Training Providing ongoing training for employees on the proper use of rigging equipment is essential. Workers should be familiar with inspection techniques and understand the importance of using high-quality rigging products.

2. Conduct Regular Inspections Establish a rigorous schedule for equipment inspections. By identifying wear and tear early, organizations can replace substandard products before they are put into use.

3. Develop a Supplier Network Building a network of reliable suppliers that offer certified rigging products can ensure access to high-quality materials. Prioritize suppliers with proven track records and positive reviews from other businesses in your industry.

4. Promote a Safety Culture Cultivating a workplace culture that prioritizes safety can encourage employees to report concerns about rigging products. An open dialogue regarding equipment safety can foster an environment where potential issues are addressed before they lead to accidents.

5. Maintain Documentation Keeping thorough records of product inspections, maintenance, and certifications can provide a comprehensive view of equipment quality. This documentation can be vital in the event of an incident, as it demonstrates a commitment to safety and compliance.

Conclusion

Bad rigging products can pose significant risks across various industries. By understanding the dangers, recognizing the signs of substandard equipment, and implementing safety measures, organizations can protect their employees and assets. Investing in quality rigging products and fostering a safety-first mindset is not just a regulatory requirement; it is an ethical obligation that safeguards lives and enhances overall operational efficiency. Ultimately, prioritizing the quality of rigging products will lead to a safer and more productive workplace.