News

ต.ค. . 18, 2024 03:29 Back to list

Supplier Solutions for Ship Rigging and Marine Equipment Services

The Role of Rigging Ship Suppliers in Maritime Operations

In the maritime industry, the role of rigging ship suppliers cannot be overstated. These suppliers play a crucial part in ensuring that vessels are equipped with the necessary rigging equipment to navigate waterways safely and efficiently. Rigging involves the process of setting up and maintaining the equipment used to support the sails of ships or to secure cargo on deck. This article delves into the significance of rigging ship suppliers, the essential equipment they provide, and the challenges they face in today’s maritime operations.

Importance of Rigging Equipment

Rigging equipment is fundamental to the safe operation of any vessel. It includes a variety of products such as ropes, chains, shackles, blocks, and other hardware used to secure and maneuver both the ship and its cargo. With the rise of global trade, the demand for reliable rigging equipment has increased, necessitating a robust supply chain to support maritime operations.

Suppliers provide not only the equipment but also the expertise to ensure that it is properly used and maintained. For instance, they may offer training sessions for crew members on the correct handling of rigging gear, ensuring safety and compliance with maritime regulations. This is particularly important given the hazards associated with handling heavy materials and navigating sometimes treacherous waters.

Types of Rigging Equipment

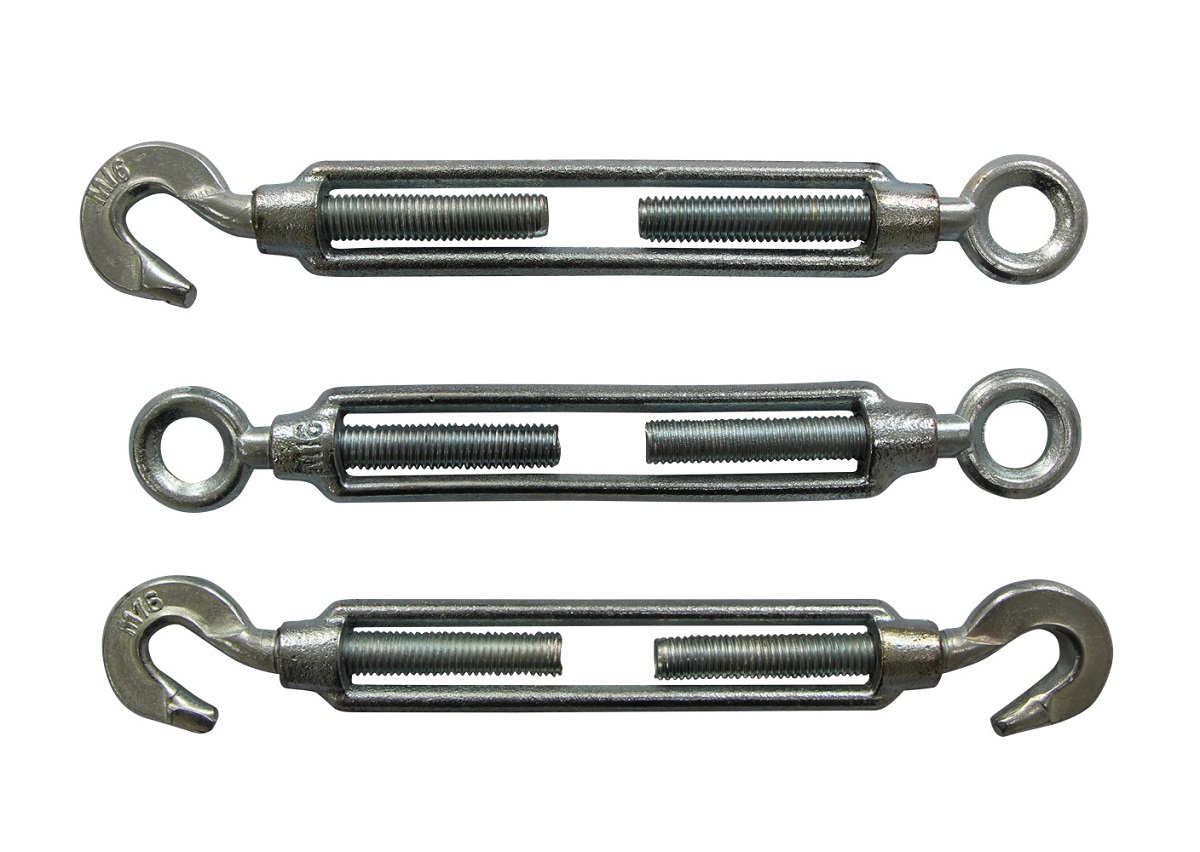

Rigging ship suppliers offer a wide range of products designed to meet the diverse needs of different vessels. Some of the most common rigging equipment includes

1. Wire Ropes Widely used for hoisting and towing, wire ropes are made from steel cables and are known for their strength and reliability. 2. Synthetic Ropes Increasingly popular for their lightweight properties and resistance to environmental factors, synthetic ropes are easier to handle and maintain.

3. Chains and Shackles Essential for securing loads, chains and shackles are fundamental components of any rigging system. Suppliers ensure that these components meet stringent safety standards.

4. Blocks and Pulleys Used to lift and lower heavy items on ships, blocks and pulleys help distribute weight evenly, making tasks safer and more manageable.

rigging ship supplier

5. Winches and Capstans These machines assist in hauling and controlling heavy loads on board, providing the necessary power to complete difficult tasks.

6. Safety Equipment This includes harnesses, lanyards, and other personal protective equipment (PPE) that are vital for the safety of crew members involved in rigging operations.

Challenges Faced by Suppliers

Despite the critical role they play, rigging ship suppliers face several challenges in the maritime industry. One major issue is the fluctuation in demand due to economic cycles. When global trade is booming, suppliers must ramp up production to meet increased demand. Conversely, during economic downturns, they may struggle with excess inventory and decreased orders.

Another challenge is the ever-evolving technology in the maritime sector. Suppliers must stay current with the latest innovations in rigging equipment to remain competitive. This requires ongoing investment in research and development, as well as training for staff to ensure that they can effectively support new products and solutions.

Furthermore, suppliers must navigate complex regulations and safety standards. The maritime industry is heavily regulated to ensure safety and environmental compliance. Suppliers must ensure that their products meet these regulations, requiring continuous quality control and testing procedures.

The Future of Rigging Supplies

Looking ahead, rigging ship suppliers will likely see an increased focus on sustainability. As the maritime industry seeks to reduce its environmental footprint, suppliers may need to explore eco-friendly materials and practices. This could involve using recyclable materials for rigging equipment or designing systems that reduce waste and energy consumption.

Additionally, advancements in digital technology, such as the Internet of Things (IoT) and automation, could reshape how suppliers do business. Smart rigging systems that monitor for wear and tear or that can be remotely controlled may soon become the industry standard.

In conclusion, rigging ship suppliers are an indispensable part of the maritime ecosystem. By providing high-quality equipment and expert knowledge, they contribute to the safety and efficiency of marine operations. As the industry continues to evolve, these suppliers will play a vital role in adapting to new challenges and opportunities, ensuring that maritime activities can proceed safely and sustainably.