News

พ.ย. . 12, 2024 21:08 Back to list

3 4 shackles factory

The Challenge of 3 4% Shackles Factory Navigating Manufacturing Innovations

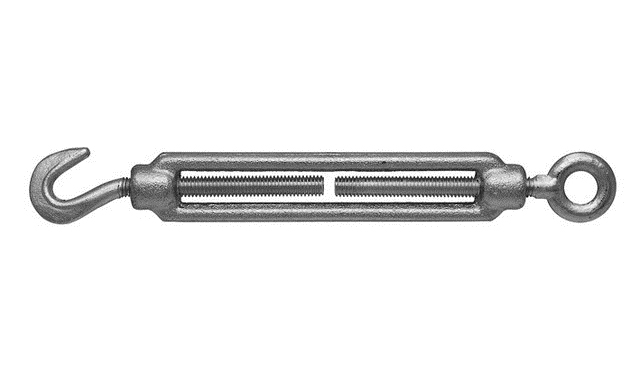

In the dynamic world of manufacturing, the realm of shackles, which are vital components in various industries including construction, shipping, and heavy machinery, faces numerous challenges and opportunities. At the core of this sector is the ongoing demand for safety, reliability, and innovation. The emergence of the 3 4% shackles factory exemplifies this delicate balance between productivity and adhering to stringent safety and quality standards. This article delves into the complexities of shackle manufacturing while highlighting the critical aspects associated with a factory focused on performance and sustainability.

The Challenge of 3 4% Shackles Factory Navigating Manufacturing Innovations

In recent years, there has been an increasing focus on sustainable manufacturing practices. The 3 4% shackles factory is likely at the forefront of this movement, implementing eco-friendly processes that minimize waste and energy consumption. Innovations such as the use of recycled materials, advanced forging techniques, and energy-efficient machinery can reduce the environmental impact of production significantly. By leveraging technology and adopting greener practices, this factory not only enhances its reputation but also appeals to a growing market segment that values sustainability.

3 4 shackles factory

Moreover, the global supply chain for shackles has become increasingly complex, especially with the fluctuations in raw material availability and costs. The 3 4% shackles factory must navigate these challenges adeptly, sourcing materials from reliable suppliers while keeping production costs in check. Developing strong relationships with suppliers and investing in local material sourcing can create a more resilient supply chain, ultimately leading to a more dependable production schedule.

Technological advancements also play a crucial role in shaping the future of the shackles industry. The introduction of automation and smart manufacturing technologies offers tremendous potential for increasing efficiency. The factory might utilize robotics for repetitive tasks, advanced software for inventory management, and AI-driven quality control systems to enhance precision. These innovations not only streamline operations but also reduce the likelihood of human error, contributing to overall product quality.

Importantly, workforce training is vital in a factory focusing on high standards such as the 3 4%. Employees must be well-versed in both traditional manufacturing techniques and modern technological tools. Continuous training programs can empower the workforce, instilling a culture of safety and excellence. A knowledgeable team is essential for maintaining the level of craftsmanship that shackles manufacturing demands.

In conclusion, the 3 4% shackles factory stands as a beacon in the manufacturing industry, navigating the complex interplay of quality, sustainability, and innovation. By emphasizing meticulous production standards, adopting eco-friendly practices, and leveraging technology, the facility is poised to meet the evolving demands of the market. As the industry continues to grow, the factory's commitment to excellence will undoubtedly play a pivotal role in shaping the future of shackle manufacturing.