News

நவ் . 26, 2024 22:35 Back to list

Manufacturers of Durable Galvanized Eye Bolts for Various Industrial Applications

The Rise of Galvanized Eye Bolt Factories A Testament to Modern Manufacturing

In the realm of manufacturing, few products are as crucial as eye bolts. These versatile fasteners find their applications in various sectors, from construction to maritime operations. Among these, galvanized eye bolts stand out due to their resistance to corrosion and durability. As industries expand and technological advancements progress, the demand for high-quality galvanized eye bolts continues to rise, leading to the proliferation of specialized factories dedicated to their production.

Understanding Galvanized Eye Bolts

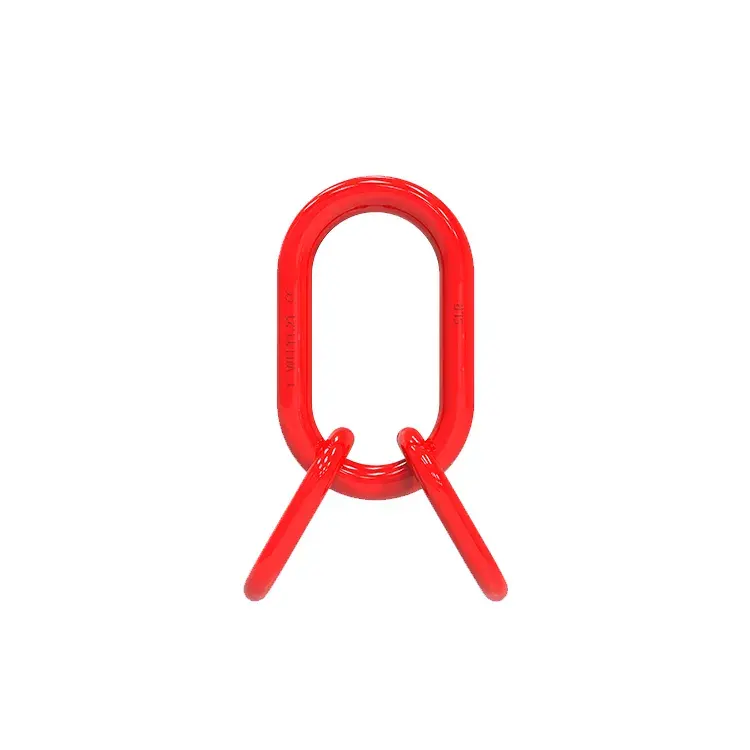

At the core of the galvanized eye bolt lies its unique design, featuring a loop (or eye) at one end that allows for easy attachment to a hook, pulley, or other lifting equipment. The term galvanized refers to the process of applying a zinc coating to the steel or iron eye bolts to prevent rust and corrosion when exposed to moisture. This galvanization process can significantly enhance the longevity of the fasteners, making them ideal for both indoor and outdoor applications.

Galvanized eye bolts come in various sizes and strengths, ensuring they meet the diverse needs of various industries. The ability to customize these components further contributes to their popularity in sectors such as construction, shipping, and even recreational activities like boating and climbing.

The Growth of Factories Specializing in Galvanized Eye Bolts

As the demand for galvanized eye bolts surges, more factories specializing in their production have emerged. This growth can be attributed to several factors. Firstly, the construction and infrastructure sectors have seen unprecedented growth worldwide. From skyscrapers to bridges, the need for reliable and durable fasteners has become paramount. Galvanized eye bolts serve as essential components in these projects, providing a safe and robust solution for lifting and rigging applications.

Secondly, technological advancements in manufacturing processes have allowed factories to produce galvanized eye bolts more efficiently and with greater precision. Automated machinery and innovative techniques, such as hot-dip galvanization, enable manufacturers to streamline production while maintaining quality control. This results in a more cost-effective product that can meet the rigorous demands of modern industry.

galvanized eye bolt factories

Additionally, the focus on sustainability has prompted factories to reevaluate their production methods. Many galvanized eye bolt manufacturers are now incorporating eco-friendly practices, from sourcing raw materials responsibly to reducing waste during the manufacturing process. This shift not only appeals to environmentally conscious consumers but also aligns with global efforts to mitigate industrial impacts on the planet.

Challenges Faced by Galvanized Eye Bolt Factories

Despite the booming demand, galvanized eye bolt factories encounter specific challenges. One primary issue is the fluctuation in raw material prices, particularly steel and zinc. These fluctuations can affect production costs and, consequently, the pricing of finished products. Manufacturers must navigate these challenges while maintaining competitive pricing to ensure profitability.

Labor shortages also pose a significant hurdle. As factories strive to keep up with increased demand, finding skilled workers capable of operating advanced machinery becomes increasingly challenging. Investing in workforce training and development is essential for these factories to maintain quality and production levels.

Furthermore, competition in the industry is fierce, with numerous manufacturers vying for market share. To stand out, galvanized eye bolt factories must ensure they produce high-quality products, leverage innovative marketing strategies, and build strong relationships with customers to foster loyalty.

Future Prospects

Looking ahead, the outlook for galvanized eye bolt factories appears promising. With ongoing advancements in technology and materials, manufacturers can expect continued improvements in product quality and efficiency. As regulations regarding safety and environmental standards evolve, there will be further opportunities for manufacturers to innovate and adapt their processes.

In conclusion, the growth of galvanized eye bolt factories reflects broader trends within the manufacturing industry. These factories play a crucial role in supporting various sectors that rely on high-quality, durable fasteners. The future holds great potential, driven by technological advancements, a focus on sustainability, and an ever-growing demand for reliable fastening solutions. As industries continue to evolve, galvanized eye bolts will undoubtedly remain a vital component of modern manufacturing, ensuring safety and efficiency across numerous applications.