News

நவ் . 01, 2024 09:58 Back to list

1% Turnbuckle Manufacturer for Quality Rigging Solutions and Durable Hardware

Exploring the World of Turnbuckle Manufacturing

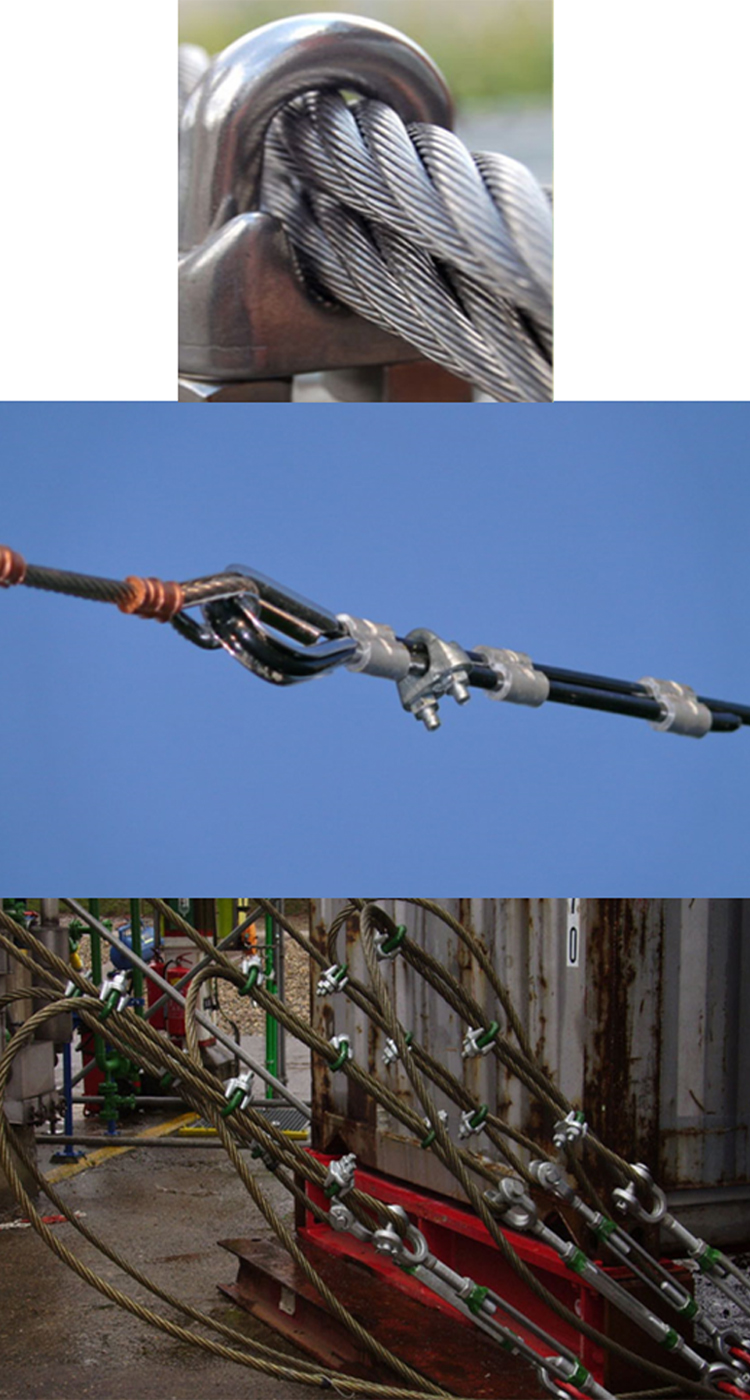

Turnbuckles are essential components in various industries, including construction, marine, and automotive. These devices are used to adjust the tension or length of cables, ropes, or tie rods, ensuring that structures remain secure and stable. As the demand for robust and reliable turnbuckles continues to grow, the importance of quality turnbuckle factories has become increasingly apparent.

Exploring the World of Turnbuckle Manufacturing

Typically, the materials used in making turnbuckles include stainless steel, carbon steel, and other alloys that offer superior strength and corrosion resistance. The choice of material is crucial, especially in applications exposed to harsh environmental conditions, such as marine or outdoor settings. A reputable turnbuckle factory not only sources high-quality materials but also employs skilled craftsmen who understand the significance of detail in fabrication.

1 turnbuckle factory

Furthermore, modern turnbuckle factories often incorporate automation into their production lines. The use of CNC machines and robotics enhances precision and efficiency, allowing for the mass production of turnbuckles without compromising quality. This automation also reduces the likelihood of human error, ensuring that each turnbuckle produced is within specified tolerances.

Quality control is another critical aspect of turnbuckle manufacturing. Factories implement rigorous testing protocols to ensure that each turnbuckle can withstand the stresses it will encounter in real-world applications. This includes tensile testing, load testing, and corrosion resistance testing. Factories that adhere to strict quality assurance practices are more likely to produce turnbuckles that exceed customer expectations and industry standards.

Sustainability is also becoming a focal point for turnbuckle factories. As awareness of environmental issues grows, manufacturers are seeking ways to minimize their carbon footprint. This includes using eco-friendly materials, optimizing energy consumption during the manufacturing process, and implementing recycling programs for scrap materials. These efforts not only benefit the environment but can also enhance a factory's reputation and marketability.

In conclusion, turnbuckle factories play a vital role in ensuring that various industries have access to high-quality, reliable fasteners. With advancements in technology and a commitment to quality control and sustainability, these factories are well-positioned to meet the increasing demand for innovative and durable turnbuckle solutions. As industries continue to evolve, the turnbuckle factory will remain a cornerstone of engineering and construction, contributing to the safety and efficiency of countless applications.