News

dec . 11, 2024 10:29 Back to list

Suppliers for Eye Nuts and Rigging Solutions in the Industry

The Importance of Choosing the Right Eye Nuts Rigging Suppliers

In the world of rigging and lifting, eye nuts play a crucial role in ensuring the safety and efficiency of various applications. These small but vital components act as anchor points in rigging systems, providing the necessary connection between the load and the lifting apparatus. As such, the selection of eye nuts rigging suppliers is critical for anyone involved in construction, shipping, entertainment, or any industry that relies on hoisting and lifting operations.

What Are Eye Nuts?

Eye nuts are specialized nuts with a ring or eye on one end, allowing a hook or other fastening device to be attached securely. They come in various sizes, materials, and load capacities, depending on the specific application. Manufactured from steel, stainless steel, or even plastic, the choice of material can heavily influence the durability and strength of the eye nut. Selecting the appropriate eye nut is essential for minimizing risks and ensuring that loads are lifted safely.

Why Supplier Selection Matters

Trusting the right supplier can make a significant difference in your rigging operations. Here are several reasons why supplier selection is paramount

1. Quality Assurance Not all eye nuts are created equal. Reputable suppliers adhere to stringent quality standards, ensuring their products meet industry specifications. Inferior materials or poorly manufactured eye nuts can lead to failures, causing serious accidents and financial losses.

2. Range of Products A good eye nuts rigging supplier will offer a vast selection of products to meet different needs. This includes a variety of sizes, materials, and designs, which enables buyers to choose the most suitable option for their specific lifting tasks.

3. Regulatory Compliance Many industries have regulations mandating specific standards for rigging and lifting equipment. Trusted suppliers will provide eye nuts that conform to these regulations, ensuring safety and legal compliance.

4. Reliability and Availability Suppliers with a solid reputation tend to maintain adequate inventory levels, making it easier for you to source eye nuts when needed. This reliability can prevent delays in projects, which can be critical in time-sensitive operations.

5. Technical Support and Expert Advice Leading suppliers often employ experts who can assist customers in selecting the best products for their unique applications. This guidance can be invaluable in optimizing lift operations and ensuring safety.

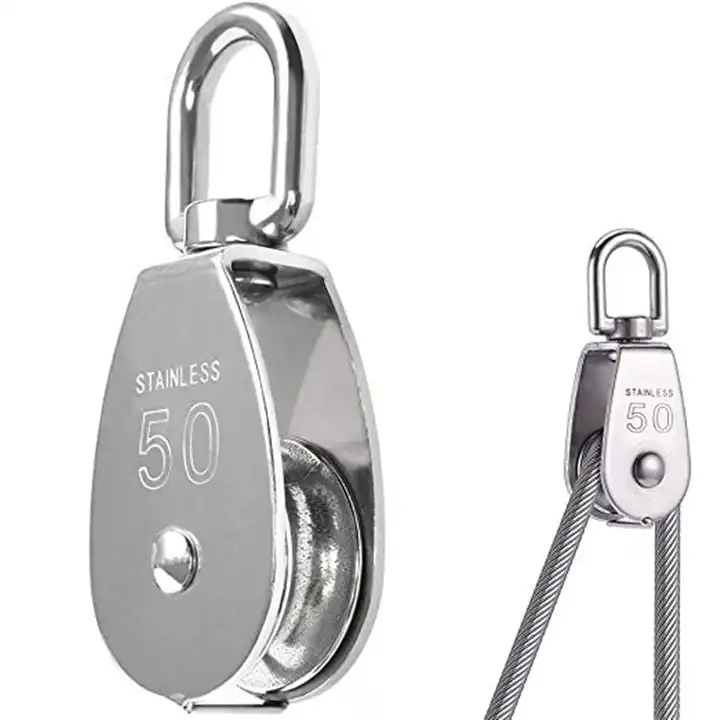

eye nuts rigging suppliers

6. Competitive Pricing While price should not be the only consideration, it is undoubtedly an important factor. Trusted suppliers tend to offer competitive pricing due to established relationships with manufacturers and efficient operation processes.

Finding the Right Supplier

To ensure optimal safety and performance, here are some steps to help you find the right eye nuts rigging suppliers

1. Research and Reviews Start by researching potential suppliers online. Look for customer reviews, testimonials, and ratings. Platforms like Trustpilot and industry-specific forums can provide insightful information about their reliability.

2. Ask for Recommendations Consult colleagues, industry partners, and other professionals in your network for recommendations. Personal experiences often carry significant weight when gauging the credibility of a supplier.

3. Check Certifications Verify that the supplier’s products meet necessary industry standards and possess relevant certifications. This may include ISO certifications or compliance with ANSI and other regulatory bodies.

4. Request Samples If possible, request product samples to assess quality firsthand. This can help ensure that the eye nuts you intend to purchase meet your expectations for durability and performance.

5. Evaluate Customer Service Pay attention to how a supplier communicates and handles inquiries. Strong customer support is essential, especially if you encounter issues or need after-sales services.

Conclusion

Selecting the right eye nuts rigging suppliers is vital for the safety and efficiency of any lifting operation. By ensuring quality assurance, a diverse product range, regulatory compliance, and support, you can significantly reduce the risks associated with rigging and lifting. Take the time to research, seek recommendations, and evaluate potential suppliers carefully, and you will ensure the success of your projects while keeping safety as your top priority.