News

aug . 21, 2024 05:18 Back to list

China G80 US Master Link Assembly Suppliers for High-Quality Chain Solutions

China G80 US Master Link Assembly Suppliers An Overview

In the global supply chain landscape, the demand for reliable and durable lifting equipment has never been higher. Among the essential components in the rigging and lifting industry, the G80 master link assembly holds a crucial position. China, being a manufacturing powerhouse, has emerged as a leading supplier of G80 US master link assemblies, catering to various industrial sectors across the globe.

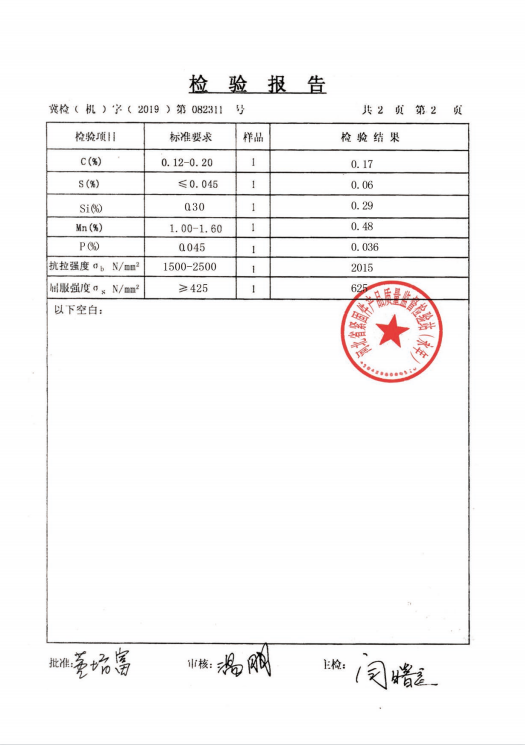

The G80 specification indicates that the master link assembly is made from high-quality alloy steel, ensuring exceptional strength and longevity. This makes it suitable for heavy lifting and hoisting applications in industries such as construction, oil and gas, shipping, and beyond. The 80 in G80 signifies that the steel used can handle a specific weight load - this level of performance is crucial for operators who need assurance that their equipment can manage significant stress without failure.

China G80 US Master Link Assembly Suppliers An Overview

Moreover, Chinese suppliers of G80 master link assemblies often adhere to international quality standards. Many manufacturers are certified by organizations such as ISO (International Organization for Standardization) and have undergone stringent quality assurance processes. This ensures that their products meet or exceed the requirements outlined in various lifting and rigging standards, including those specified by the American National Standards Institute (ANSI) and the Occupational Safety and Health Administration (OSHA). Thus, when purchasing from these suppliers, buyers can have confidence in the integrity and safety of the products.

china g80 us master link assembly suppliers

However, while sourcing from China, buyers should exercise due diligence. The sheer number of suppliers can be overwhelming, and ensuring the credibility of manufacturers is crucial. Potential buyers should look for suppliers that provide detailed product specifications, quality certifications, and can demonstrate a history of customer satisfaction. Additionally, engaging in direct communication with suppliers can help clarify any potential concerns regarding product specs, delivery times, and post-purchase support.

The logistics of procuring G80 US master link assemblies from China can also play a significant role in decision-making. With global shipping routes becoming increasingly efficient, it is relatively easy to import products; however, potential buyers should consider shipping costs, lead times, and customs duties. Collaborating with experienced freight forwarders and understanding the import regulations of one’s country can streamline the process.

Finally, trends in the market are leaning towards sustainability and environmentally-friendly manufacturing practices. As awareness around climate change and environmental impact grows, suppliers that prioritize sustainable practices may become more attractive to businesses focused on Corporate Social Responsibility (CSR). Buyers might find suppliers that utilize eco-friendly materials or adopt processes that minimize energy consumption, aligning with their own ethical commitments.

In conclusion, sourcing G80 US master link assemblies from Chinese suppliers presents a range of benefits, including cost efficiency and high standards of quality. Thorough research and careful supplier selection are essential, ensuring that businesses can access reliable products for their lifting and rigging needs. As the global demand for robust lifting equipment continues to rise, China will likely remain a key supplier for these critical components, shaping the future of the industry.