News

nov. . 07, 2024 21:18 Back to list

Overview of Various Types of Rigging Equipment Used in Industries

Understanding Rigging Equipment An Essential Component of Various Industries

Rigging equipment is a critical aspect of many industries, including construction, shipping, and entertainment. It includes a wide variety of tools and tools that facilitate lifting, pulling, and securing heavy loads with safety and efficiency. With the demand for reliable and effective rigging solutions continually growing, it’s paramount to understand the various components involved and their applications.

Types of Rigging Equipment

The rigging equipment spectrum encompasses several key items

1. Lifting Slings These are flexible straps used to lift and move loads. Lifting slings can be made of various materials, such as nylon, polyester, or chain, each having unique characteristics and load capacities. The choice of sling depends on the specific application, including the weight, shape, and nature of the load being moved.

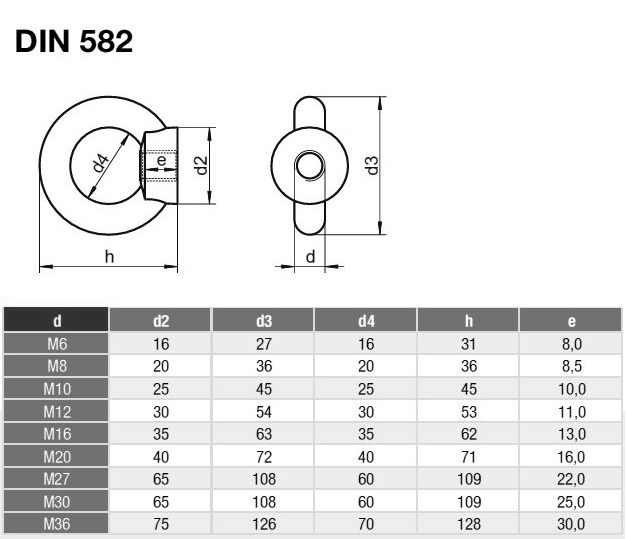

2. Shackles Shackles are metal hardware devices used to connect components in a rigging system. They come in various shapes, including bow and chain shackles, and are vital for linking slings, chains, and other lifting equipment. The load capacity of a shackle is crucial, and it's essential to choose the appropriate size and type for the application to ensure safety.

3. Hooks Hooks are versatile rigging tools used to connect slings and chains to the load. There are numerous styles, such as grab hooks, sling hooks, and swivel hooks, each designed for specific tasks. The robustness and reliability of hooks are vital for securing loads, preventing accidents during lifting operations.

4. Winches Winches are mechanical devices utilized to pull, lift, or lower loads through a winding drum or wheel mechanism. They can be manual or powered, depending on the lifting capacity required. Winches are especially prevalent in construction and maritime environments, facilitating the movement of heavy materials.

rigging equipment includes: product

5. Pulleys Pulleys are another crucial element in rigging. They make it easier to lift heavy loads by changing the direction of force. When used in combination with other rigging equipment, pulleys can greatly reduce the effort needed to lift loads, enhancing efficiency and safety.

Applications of Rigging Equipment

Rigging equipment plays a pivotal role in numerous sectors. In construction, it is used extensively for moving heavy materials, from steel beams to concrete blocks, ensuring safety and precision when erecting structures. In the maritime industry, rigging equipment facilitates loading and unloading cargo from ships, making it essential for global trade and transport. Additionally, in the entertainment industry, rigging is used for stage setups, ensuring the safe and effective movement of lights, sound equipment, and scenery during performances.

Safety Considerations

With the importance of rigging equipment comes the critical necessity for safety. Each component must be properly maintained, inspected regularly, and used according to the manufacturer’s specifications to prevent accidents. Training personnel in the correct use of rigging equipment is essential to promote a culture of safety in the workplace. Operators should be well-versed in weight limits, usage protocols, and emergency procedures to mitigate risks associated with heavy lifting.

Conclusion

In conclusion, rigging equipment is an indispensable element across various industries, supporting the safe and efficient movement of heavy loads. Understanding the different types of equipment, their applications, and adhering to safety measures are vital for anyone working in environments where rigging is in play. As industries continue to evolve, so too will the technology and techniques surrounding rigging, ensuring these tools remain effective in handling the challenges of lifting and securing loads. Investing in quality equipment and training will not only enhance operational efficiency but will also safeguard the well-being of all personnel involved in rigging operations.