News

dec. . 24, 2024 19:21 Back to list

concrete eye bolt manufacturer

The Role of Concrete Eye Bolt Manufacturers in Construction

In the realm of construction and civil engineering, the significance of reliable fastening systems cannot be overstated. One crucial component that often goes unnoticed yet plays an integral role in securing structures is the concrete eye bolt. As a specialized type of anchor, concrete eye bolts are designed for use in concrete, typically allowing for connection points for cables, ropes, chains, or other fastening materials. This article delves into the importance of concrete eye bolt manufacturers, their production processes, and the impact of their products on construction projects.

Understanding Concrete Eye Bolts

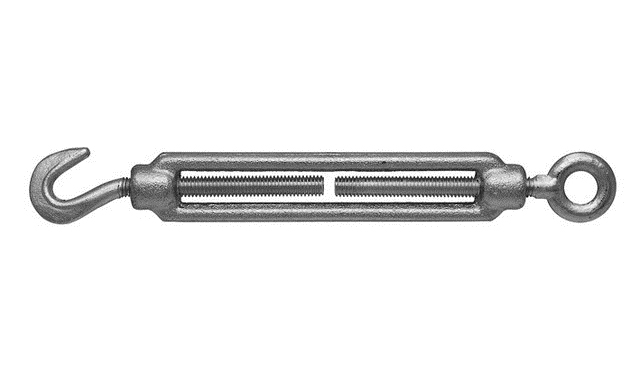

Concrete eye bolts are essentially circular bolts that have a loop or “eye” at one end. This eye provides a convenient connection point for various rigging and lifting applications. The threaded end of the eye bolt is embedded in the concrete, ensuring a secure hold. These bolts come in various sizes and grades, catering to different weights and stress levels inherent in construction environments.

Their applications are vast, ranging from the suspension of signage and lights to the attachment of heavy machinery and support structures. In marine environments, these bolts are especially valuable for securing boats and docks. The durability and strength of concrete eye bolts make them a go-to choice for engineers and contractors looking for reliable fastening solutions.

Manufacturing Process

The manufacturing of concrete eye bolts is a meticulous process that requires precision and attention to detail. Typically, manufacturers use high-quality steel or stainless steel in the production of these bolts to ensure they can withstand the stresses and harsh conditions they may encounter.

1. Material Selection The first step in the manufacturing process is the selection of durable materials. High-strength steel is often preferred for its superior load-bearing capacity and resistance to corrosion.

2. Forging and Shaping Once the materials are selected, the metal is shaped through a forging process. This involves heating the steel and then applying pressure to form the desired shapes. This process enhances the mechanical properties of the metal, making it tougher and more resilient.

3. Machining After forging, the bolts go through precision machining to create the threaded ends and the eye loops. This stage is critical, as the accuracy of the threads directly impacts the bolt's ability to hold firmly when embedded in concrete.

concrete eye bolt manufacturer

4. Finishing Following machining, the bolts undergo finishing processes such as polishing, coating, or galvanizing. These processes help protect against rust and corrosion, thereby increasing the lifespan of the product.

5. Quality Control The final stage involves stringent quality control measures. Each batch of concrete eye bolts is tested for strength and durability, often through tensile testing. Only those that meet the specified standards are packaged and dispatched.

The Importance of Quality Manufacturers

Choosing the right manufacturer for concrete eye bolts can make a significant difference in the success of a construction project. Quality manufacturers prioritize safety and reliability—two essential elements in construction.

1. Safety Standards Reputable manufacturers comply with international safety standards, ensuring that their products are reliable and safe to use. This compliance protects not only the integrity of the construction project but also the lives of workers and users.

2. Customization Many established manufacturers offer tailor-made solutions to meet specific project requirements. This customization can include variations in bolt size, material grade, and even special coatings for environments prone to corrosion.

3. Innovation Leading manufacturers are at the forefront of technology and innovation, continually improving their products to enhance performance. Research and development efforts often lead to new types of eye bolts designed for innovative applications, ensuring that they meet modern construction demands.

4. Customer Support A dedicated customer service team is crucial for assisting contractors and engineers in selecting the right products for their projects. Quality manufacturers provide expert advice, technical support, and product warranties, building trust with their clients.

Conclusion

In summary, concrete eye bolt manufacturers play a pivotal role in the construction industry. Their expertise in producing high-quality, reliable fastening solutions ensures the safety and durability of structures across the globe. By focusing on robust manufacturing processes and adhering to stringent quality standards, these manufacturers contribute significantly to the success of construction projects, making them indispensable partners in the building process. Ultimately, the choice of a concrete eye bolt can influence not only the integrity of a project but also the safety of its future users, underscoring the importance of selecting a reputable manufacturer.