News

Nov . 07, 2024 23:04 Back to list

Different Varieties of Wire Rope Clips for Various Applications and Uses

Types of Wire Rope Clips A Comprehensive Overview

Wire rope clips, also known as wire rope clamps, are essential components in rigging and lifting applications. They are crucial for securing wire ropes at various points, making them indispensable in industries ranging from construction to maritime operations. Understanding the different types of wire rope clips available can help you choose the right one for your specific needs.

1. Standard Wire Rope Clips

Standard wire rope clips are the most commonly used type. They typically consist of a U-shaped bolt, a saddle, and two nuts. The wire rope is looped back on itself and secured by the clip. These clips are versatile and can be used for a variety of applications; however, they are most effective when applied to single-strand or multi-strand rope configurations. Standard wire rope clips are made from materials ranging from stainless steel to galvanized steel, providing varying levels of corrosion resistance depending on the application.

2. Double Saddle Wire Rope Clips

Double saddle wire rope clips are designed to provide a more robust and stable hold on heavier loads. They feature two saddles instead of one, increasing the surface contact area and distributing the load more evenly. This design minimizes wear on the wire rope and enhances strength, making them ideal for applications with high stress and dynamic loads, such as in elevators or cranes. While they may be slightly more expensive than standard clips, the added durability often justifies the cost.

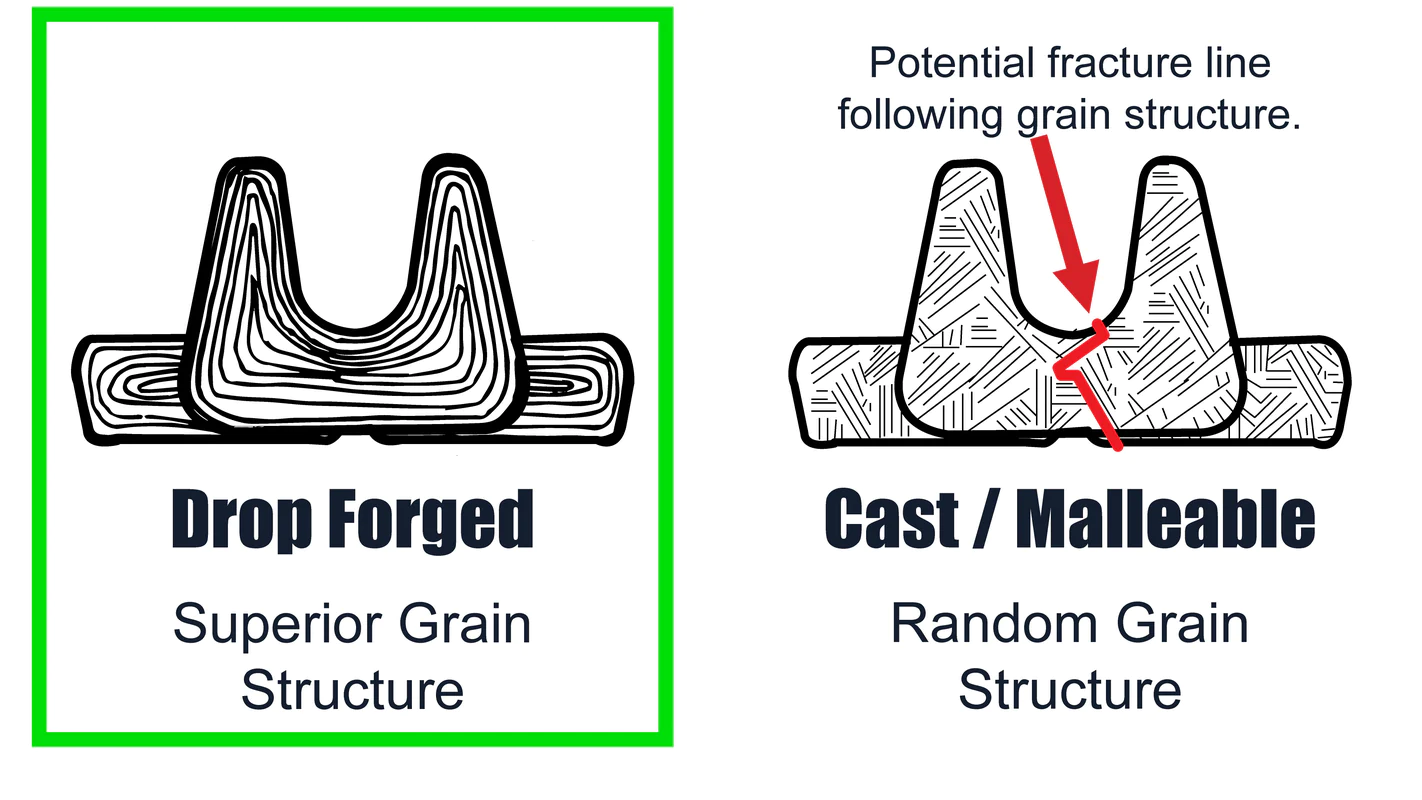

Forged wire rope clips are manufactured through a forging process, which involves shaping the metal using localized compressive forces. This method results in a stronger and more durable clip that can withstand extreme conditions. Forged clips are particularly beneficial in high-stress applications, such as suspension bridges or large cranes, where safety is paramount. Though they may be more expensive than their cast counterparts, their strength and reliability make them a preferred choice in critical lifting operations.

types of wire rope clips products

4. Cast Wire Rope Clips

In contrast to forged clips, cast wire rope clips are made from metal that has been melted and poured into molds. While they can be produced more cheaply, they are generally less robust than forged clips. Cast wire rope clips may be suitable for lighter-duty applications or where the risk of failure is less critical. However, it is essential to avoid using cast clips in situations where high loads or dynamic stresses are present.

5. Special-purpose Wire Rope Clips

Certain applications may require specialized wire rope clips designed for specific conditions. For instance, marine-grade wire rope clips are often treated with coatings to resist saltwater corrosion, making them ideal for marine applications. Similarly, high-temperature wire rope clips are engineered to withstand extreme heat conditions, suitable for industries like steel manufacturing and foundries.

6. Size and Material Considerations

When selecting wire rope clips, it’s essential to consider the size of the wire rope and the material of the clip. Typically, wire rope clips are available in various sizes to accommodate different wire diameters. The material should also be chosen based on environmental conditions—stainless steel clips offer excellent corrosion resistance, while galvanized options provide moderate protection.

Conclusion

In summary, wire rope clips are vital tools for securing wire ropes in diverse applications. From standard clips to specialized variants, understanding the different types available can help ensure that you choose the right clip for your needs. Whether you are involved in construction, maritime operations, or other fields requiring heavy lifting, selecting high-quality wire rope clips will contribute to the safety and efficiency of your operations. Always remember to adhere to manufacturer guidelines regarding the use and maintenance of wire rope clips to maximize their lifespan and effectiveness.