News

Aug . 30, 2024 12:09 Back to list

Quality ODM DIN 580 Products – Reliable Lifting Solutions

Understanding ODM DIN 580 Products A Comprehensive Overview

In today’s industrial landscape, the demand for high-quality and reliable lifting solutions continues to grow. One such solution is the ODM DIN 580 products, which are essential components in various lifting applications. The DIN 580 standard pertains to lifting eyes, which are designed to provide a secure and effective means for attaching loads to lifting equipment. This article explores the significance of ODM DIN 580 products, their features, applications, and benefits.

What are ODM DIN 580 Products?

ODM stands for Original Design Manufacturer, which implies that the manufacturer designs and produces components based on specific industry standards. The DIN 580 standard, established by the German Institute for Standardization, outlines the specifications for lifting eyes, which are forged or cast components used to create a lifting point on loads. These products are vital for ensuring safe and efficient lifting operations in various sectors, including construction, shipping, and manufacturing.

Key Features of ODM DIN 580 Products

1. Material Quality ODM DIN 580 products are typically made from high-strength steel, ensuring durability and resistance to wear and tear. The choice of material is crucial as it directly impacts the load capacity and safety of the lifting procedure.

2. Design Specifications The design of these lifting eyes adheres to stringent DIN standards, which dictate dimensions, load ratings, and design criteria. This ensures that each product meets rigorous safety and performance requirements.

3. Load Capacity ODM DIN 580 products are available in various load capacities, allowing users to select the appropriate lifting eye based on the specific requirements of their lifting application. This versatility is essential for operations that handle a range of different weights.

4. Corrosion Resistance Many ODM DIN 580 products undergo treatments such as galvanization to enhance their resistance to corrosion. This makes them suitable for both indoor and outdoor applications, where exposure to harsh environmental conditions is a concern.

Applications of ODM DIN 580 Products

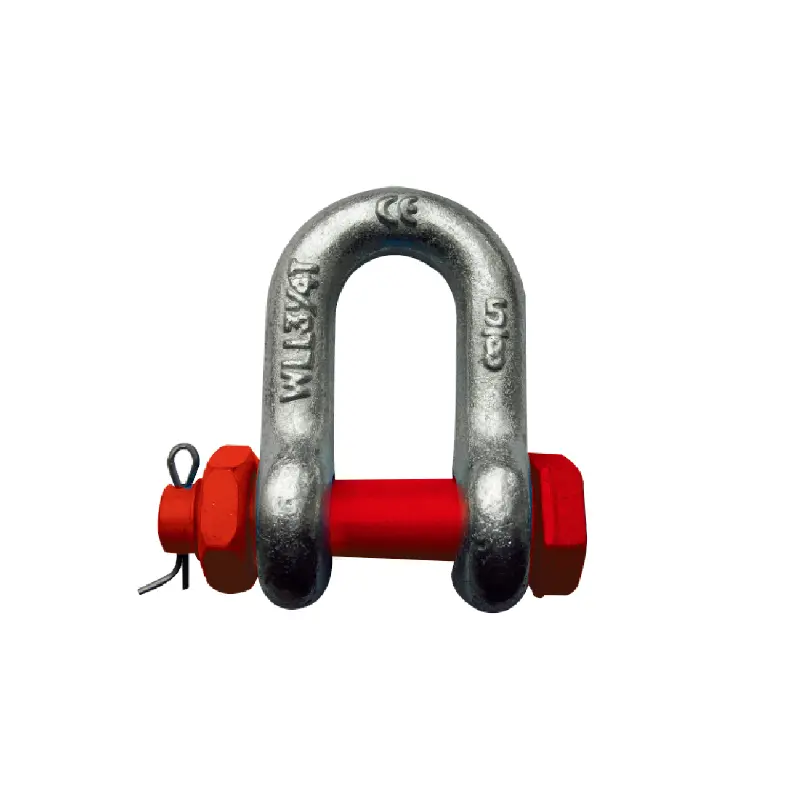

odm din 580 products

The versatility of ODM DIN 580 products allows for their use across various industries

. Common applications include- Construction In construction sites, lifting eyes are used to hoist heavy materials such as steel beams and concrete blocks, making it easier to maneuver large objects efficiently.

- Manufacturing In manufacturing facilities, lifting eyes are vital for assembly lines, where they facilitate the handling of heavy machinery and materials.

- Transportation and Logistics Within shipping and logistics, ODM DIN 580 products are used to secure loads on containers and trucks, ensuring safe transport.

Benefits of Using ODM DIN 580 Products

1. Enhanced Safety By adhering to established industry standards, ODM DIN 580 products contribute to safer lifting operations, reducing the risk of accidents and injuries.

2. Efficiency The reliability and strength of these lifting eyes streamline operations, allowing for quicker and more effective handling of heavy materials.

3. Cost-Effectiveness With their durability and longevity, ODM DIN 580 products minimize the need for frequent replacements, leading to long-term cost savings for businesses.

In conclusion, ODM DIN 580 products play an indispensable role in the realm of lifting applications. With their robust design, adherence to safety standards, and wide-ranging applications, these lifting eyes are essential for ensuring both efficiency and safety in various industries. As the demand for safe lifting solutions continues to rise, the significance of ODM DIN 580 products cannot be overstated. Adopting these components into lifting operations will undoubtedly enhance overall productivity and safety.