News

Oct . 15, 2024 09:33 Back to list

custom g2150 shackles manufacturers

Custom G2150 Shackles Manufacturers A Guide to High-Quality Solutions

When it comes to the world of lifting and rigging, the importance of high-quality hardware cannot be overstated. One of the critical components in this realm is shackles, specifically the G2150 model. These shackles are renowned for their reliability and versatility, making them essential tools for various industries, including construction, maritime, and heavy machinery. In this article, we will explore the importance of custom G2150 shackles and the manufacturers that specialize in their production.

Understanding G2150 Shackles

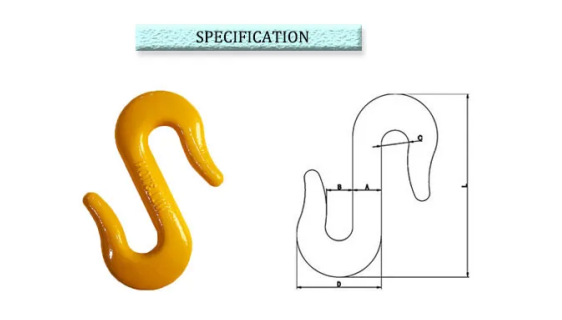

The G2150 shackle is a type of bow shackle known for its unique shape and robust design. These shackles are typically made from high-strength steel, allowing them to handle significant loads while maintaining safety. The standard design features a pin that is either screw-type or quick-release, making it easier to secure and release during operations. The G2150 shackle is often used in applications where multi-directional loading occurs, enhancing its versatility across various lifting situations.

The Need for Custom Solutions

While the G2150 shackle is widely used, the demands of different projects can vary greatly. This is where custom shackles come into play. Manufacturers that specialize in producing custom G2150 shackles can tailor their products to meet specific requirements, such as altered dimensions, enhanced load ratings, or unique finishes for environmental resistance. Custom shackles ensure that businesses receive solutions specifically designed for their operational needs, thereby increasing efficiency and safety.

Choosing the Right Manufacturer

When selecting a manufacturer for custom G2150 shackles, several factors should be considered

custom g2150 shackles manufacturers

1. Quality Standards Look for manufacturers that adhere to industry standards, such as ASTM or ISO certifications. High-quality shackles are critical for safety and performance.

2. Experience and Expertise Companies with extensive experience in the field are more likely to produce reliable products. Consider manufacturers with a track record of supplying shackles to reputable industries.

3. Customization Capabilities Not all manufacturers offer extensive customization. Choose a provider that can work closely with you to develop shackles tailored to your specifications.

4. Material Sourcing The materials used in shackle production greatly influence their strength and durability. Ensure that the manufacturer sources high-quality steel and other materials.

5. Post-Sales Support A reliable manufacturer should provide ongoing support, including guidance on installation, maintenance, and safety protocols.

Conclusion

In the realm of lifting and rigging, custom G2150 shackles represent a critical component that can significantly enhance operational efficiency and safety. Collaborating with reputable manufacturers who specialize in these shackles ensures that businesses can access high-quality, tailored solutions that meet their specific needs. As industries evolve, the demand for customized lifting solutions will continue to grow, emphasizing the importance of partnering with manufacturers committed to excellence and innovation. Whether you're in construction, maritime, or any sector requiring lifting equipment, investing in custom G2150 shackles is a decision that can lead to improved performance and safety on the job site.