News

des . 12, 2024 10:53 Back to list

lifting eye bolt service

Understanding Lifting Eye Bolts and Their Service

Lifting eye bolts are crucial components in rigging operations, commonly used for attaching lifting equipment to loads. They are engineered to provide a secure fastening point, making them essential in various industries, including construction, shipping, and manufacturing. This article delves into the importance of lifting eye bolts, their design features, and best practices for maintenance and service.

What Are Lifting Eye Bolts?

Lifting eye bolts are threaded bolts with a loop at one end, designed to be used as attachment points for lifting slings, chains, or hooks. They come in various sizes, materials, and load ratings, allowing users to choose the appropriate type for their specific applications. Typically made from steel, stainless steel, or other alloys, these bolts are engineered to withstand significant loads while ensuring safety during lifting operations.

Types of Lifting Eye Bolts

Lifting eye bolts can be categorized into two main types vertical lift eye bolts and side lift eye bolts.

- Vertical Lift Eye Bolts are designed to be loaded in a straight up-and-down motion. They are typically used in applications where the load is applied directly above the bolt, making them highly reliable for vertical lifting.

- Side Lift Eye Bolts, on the other hand, can handle loads applied from the side. These bolts are often used in situations where the load must be pulled horizontally or at an angle. However, it's vital to note that using side lift eye bolts in a vertical position can diminish their load capacity, posing a safety risk.

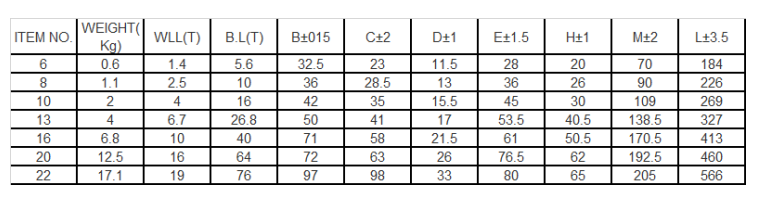

Load Ratings and Specifications

When selecting a lifting eye bolt, it is critical to consider its load rating, which indicates the maximum weight the bolt can safely support. The load rating is influenced by the design, material, and installation method. Most eye bolts are rated according to the working load limit (WLL), which is a critical metric to ensure safety. Users should always verify the load rating against the intended application to prevent accidents caused by overloading.

lifting eye bolt service

Installation and Safety Considerations

Proper installation is essential for ensuring the performance and safety of lifting eye bolts

. Here are some best practices for installation and use1. Thread Engagement Ensure that the eye bolt is threaded into the load at least the full depth of the bolt's threads. Insufficient thread engagement can lead to bolt failure.

2. Load Direction Always use the lifting eye bolt in accordance with its designated load direction. Misusing the bolt can significantly reduce its load capacity.

3. Inspection Regularly inspect eye bolts for signs of wear, corrosion, or damage. Any compromised eye bolt should be replaced immediately to maintain safety.

4. Environmental Considerations Take into account the environmental conditions where the eye bolt will be used. For instance, stainless steel eye bolts are preferred for harsh, corrosive environments such as maritime settings.

5. Training Ensure that all personnel involved in lifting operations are adequately trained on the proper use and inspection of lifting eye bolts.

Maintenance and Service

Ongoing maintenance of lifting eye bolts is vital for ensuring their longevity and reliability. Regular checks should include assessing the threads for wear, checking for corrosion or rust, and ensuring that the eye itself is not deformed. Lubrication may also be necessary for certain applications to prevent rust and ensure smooth operation.

In conclusion, lifting eye bolts serve as critical components for safe lifting processes in various industries. Understanding their types, load ratings, and installation requirements is essential in preventing accidents and ensuring operational efficiency. By adhering to best practices for installation and maintenance, users can enhance the safety and longevity of lifting eye bolts, ultimately contributing to more effective rigging operations.