News

May . 07, 2024 12:11 Back to list

Eye Nut: The Complete Guide

Eye Nut: The Complete Guide

An eye nut is an exceptional pole line hardware and fastener used for pole line and overhead line construction.

When you make a decision to purchase this fastener, always search for one that is very easy to install.

You should always search for one that is reliable.

As you read this guide, you will be able to learn about installation and application, eye nut manufacturing process, why you need it, types, specifications, and other aspects that are very important.

For more details, read on.

What is an Eye Nut?

Eye nuts are general fasteners that have a looped head.

They are made to receive ropes or hooks.

Eye nuts are famous and rated due to their unique application types.

They are round and oval in shape.

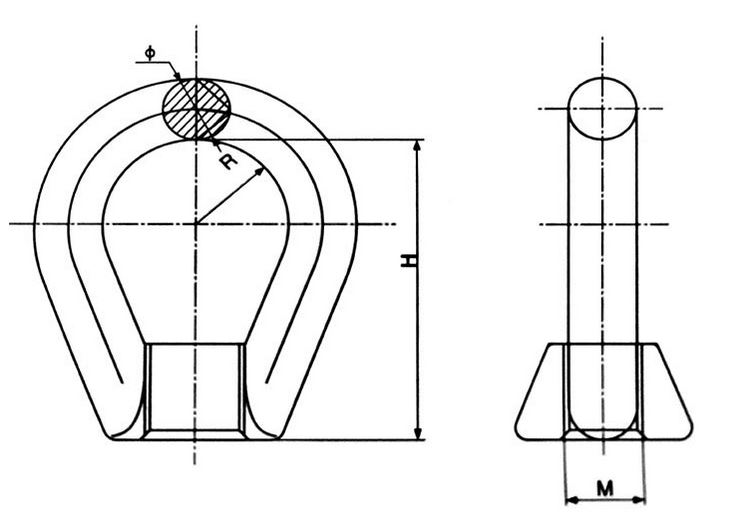

Below is a picture of eye nuts:

Just as you can see in the picture above, an eye nut is a unique hardware accessory that is mostly used on poles.

They are mostly used for dead ending, back guying, and attaching pole head guys on threaded ends of cross bolts.

Eye nut is also beneficial and helps with installations on overhead power lines as well as pole constructions.

There are load-rated eye nuts.

They are made mostly for vertical lifting.

However, they aren’t recommended to be used with angular lifts.

For eye nuts that aren’t load-rated, they are used with guiding wires and tie downs.

They should not be used for lifting applications.

Due to the above details, this accessory is very important.

Why You Need Eye Nut?

Since we now know what an eye nut is, why is it needed?

Most times, there are many people I find asking this question whenever they hear about this accessory.

Eye nuts are needed to ensure installations on poles and power line constructions are easily done.

Their main application is through dead ending, back guying, and attaching pole head guys on threaded ends of cross bolts.

They ensure cables are firmly attached to these overhead power lines and poles.

Cables must always be firm to these poles and power lines.

Types of Eye Nuts

Now, you need to know that eye nuts come in three different types.

Yes.

This is what helps to make their uses exceptional.

They are the thimble eye nut, angle thimble eyelet, and the oval eye nut.

i. Thimble Eye Nut

Thimble eye nuts are brought together with thread ends of 1/2 or 5/8 inch eye bolts.

These go across wooden poles to support strain insulators to dead end wires.

Below is a picture of a thimble eye nut.

This picture shows how much resemblance it has with an eye nut.

No wonder it is a type of eye nut.

Thimble eye nut

So, what makes a thimble eye nut unique?

Thimble eye nuts are generally made from high quality forged steel.

They are used to make installation of cables on poles and power lines very smooth.

ii. Oval Eye Nut

Oval eye nits are designed mostly for use on ½ or 5/8 inch threaded end machine bolts.

These are passed in a vertical way through cross arms to have dead end clamps attached.

Oval nuts

Another type of eye nut is the oval nut.

Oval nuts are made from galvanized steel.

Their length will always differ based on what you need them for.

It is used more for machine bolt purposes.

I continue with some of the important details to know about the oval nut.

- They are used for guying and dead ending from threaded ends of cross arm bolts.

- They are rated to aid different loads. You need to find out from the manufacturers and make sure what you need is what you get.

- They always come with unique specifications depending on your needs or customizations.

iii. Angle Thimble Eyelet

Angle Thimble Eyelets

Angle thimble eyelets are mostly used to attach to thru-bolt or thread ends of angle or straight thimble eye bolts mainly for down guying.

It is also a fastener as well as pole line hardware.

It is made from forged steel material.

In its finished state, it is hot dip galvanized in order to meet the right specifications.

How to Manufacture Eye Nuts

How are eye nuts made?

Although this might seem like a question that should not be asked, I know quite a number of people who have such thoughts in mind.

So, if you have been wondering how eye nuts are manufactured, read on.

The actual method used to make eye nuts is the drop forging method.

The material here used is the steel rod.

Now the actual manufacturing process in the steps below:

- The steel rod is heated to become very hot (red-hot).

- The red rod is then shaped by a localized compressive force.

- Through unique tooling methods, it creates thimble eye nuts and oval eye nuts (this is where these types of eye nuts are manufactured).

- Forged eye nuts are then polished.

- After that drop forging is done to ensure its strength is highly kept.

You need to also know the following:

- In the finished product, there are mostly threads in its middle.

- These threads will depend on the bolt which eye nuts are linked with.

- The threads within eye nits are drilled with the bench drilling machine.

- It is the thread of the eye nut that makes it very easy to use.

Additionally, the surface treatment of eye nuts is mostly hot dip galvanized.

Installing Eye Nuts on Poles or Overhead Power Lines

It is sad how most people feel installing eye nuts is complicated.

The truth is that the process of installation is very easy.

You just need to be cautious of the installation process.

Follow the right steps to achieve the best results.

- Start by assembling it with its thread end

- Make sure the threads go over correctly across wooden poles. This must be done to ensure strain insulators are supported to the dead end wire.

Basically, you don’t need any technical experience and know-how to install eye nuts.

DIN580 Lifting Eye bolt

Technical Specifications of Eye Nuts

Before you decide to purchase eye nuts, make sure you check out the specifications below.

· Type of Material

Eye nuts mostly come in different materials and finishes.

When you decide to purchase eye nuts, you need to know that the metallic types are made of:

- Aluminum is mostly light compared to steel. However, it is not strong compared to steel.

- Steel

- It is a metal used mostly in the aerospace world or industry. It is ideal for specific applications.

- Stainless steel. This material mostly doesn’t need anti-corrosion coatings. It, however, cannot be hardened to the same level as carbon steels.

- It is a common copper based alloy.

- Hardened steel

- It is another common copper based alloy.

- Proprietary alloys

A variety of carbon steel and alloy steel grades are used in making fasteners.

How are eye nuts finished?

These are some of the popular finishes to note.

Where finishes of eye nuts are concerned, they are mostly galvanized, anodized, gold plated, tin plated, silver plated or zinc plated.

Zinc chromate finishes for eye nuts are also available.

What about the coating of eye nuts, you might wonder?

Black oxide is used to coat eye nuts.

This is because it doesn’t lead to dimensional changes.

Phosphate coatings are also used.

This is because they provide resistance to corrosion and the best surface for the adhesion of paints and primers.

- Design of Eye Nuts: Eye nuts are designed in an oval or round shape. This is done to make their use very easy.

- Threads: Eye nut threads are mostly per bolts that eye nuts are adjoined with. These threads within eye nuts are drilled by bench drill machines. This makes installations easier. Even though most eye nuts have threads, untapped eye nuts are available too.

- Surface Treatment: These treatments of surfaces mostly differ from one eye nut to the other since finishes and coatings aren’t the same too.

- Dimensions: Dimensions of eye nuts will always differ based on your needs. Make sure you know what you need and purchase them as it should be. Just as their dimensions differ, their weight also differs.

- Maximum load capacity: This has to do with the maximum load that eye nuts can handle.

- Inside diameter or width: This is also known as the bail size. It is known as the ball diameter for round eye nuts and bail width for oval eye nuts.

- Bell diameter: It is a unique measurement of eye nuts section with the tap.

Frequently Asked Questions and Answers on Eye Nut

It is normal to have so many questions about eye nuts.

Never mind, this is the part where such questions are answered.

These questions are some common questions that people ask me daily.

Eye Nut Technical Specifications

I believe the answers to these questions will provide solutions to many people and make their use of eye nuts better.

What are the main applications of eye nuts?

You can use eye nuts for a wide range of applications.

For instance, load-rated types are made more for vertical lifting, do not use them with lifts that are angular.

For eye nuts that aren’t load-rated, they can be used with tie downs and guiding wires, they aren’t recommended for lifting uses.

What types of eye nuts will work for me?

Currently, there are many kinds of eye nuts.

You can find the oval eye nut, thimble eye nut, clevis eye nut and angle thimble eyelet.

Since their sizes vary in inches, you need to weigh the job at hand in order to make the right purchases.

Also, if you have much experience in this field, you will be able to decide with ease.

Just be sure of your specific need for it.

What is the average cost of an eye nut?

The price of eye nuts will never be the same, they will be different from one manufacturer to the other.

Make sure that you always choose suppliers that can be trusted.

Should I read eye nut manuals?

Yes, the manuals that you find in eye nut boxes are very important.

You need to take them very seriously. Follow every instruction that the eye nut manufacturer has highlighted in the manual.

Can I install eye nuts without prior experience?

It might be easy for you to do that.

However, you need to consider the gravity of the project at hand.

If the project is too complicated on its own, make sure you call an expert.

Most people have followed the right videos they obtained online and have benefited from them, you can do the same.

However, if you realize it is just not your thing, call in an expert, that will make your work easier.

Is safety wear important in installing eye nuts?

Yes, it is your duty to protect yourself when going about fastener or pole line hardware installations.

You should have your helmets, gloves, goggles, etc.