News

May . 06, 2024 17:16 Back to list

What Are Wire Rope Clips and How to Use Wire Clamps?

What Are Wire Rope Clips and How to Use Wire Clamps?

What is a wire rope clip?

A wire rope clip is an essential tool with multiple names, including wire rope clamp, wire cable clamp, wire clamp, and U-bolt. This versatile tool makes eye-loop connections or joins two wire rope cable ends together. The traditional style of this clip consists of three components: a U-shaped bolt, a forged or cast iron saddle, and two nuts.

Wire rope clips materials

Various materials and finishes are available for wire rope clips, but they can be categorized into three main types: carbon steel, cast or malleable iron, and stainless steel. These materials offer different levels of strength, durability, and resistance to corrosion, allowing users to choose the most suitable option for their specific needs.

Wire rope cable clamps come in two primary materials: carbon steel and stainless steel. Carbon steel clamps are often galvanized, which means they have an added layer of zinc to prevent rust and scratching. The addition of carbon also makes these clamps harder and more vital. However, stainless steel clamps are better for applications in saltwater environments or other highly corrosive settings. They are naturally resistant to rust and corrosion, making them a more durable option.

Din 741 Malleable Wire Rope Clips

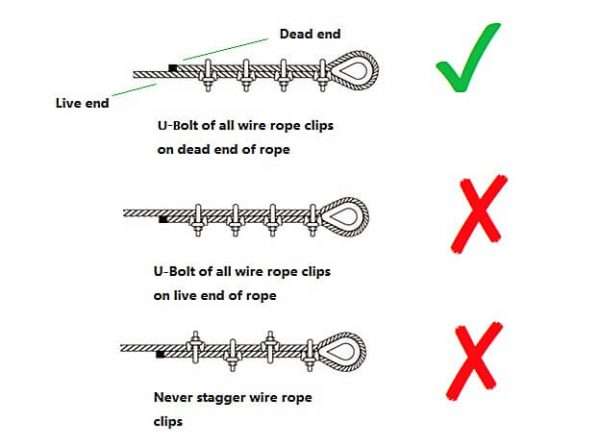

Number, spacing, and orientation of wire rope clips

- Wire rope clips number: Under normal circumstances, there are no less than 3 wire rope clips

- Wire rope clip spacing: generally 6~7 times the diameter of the wire rope.

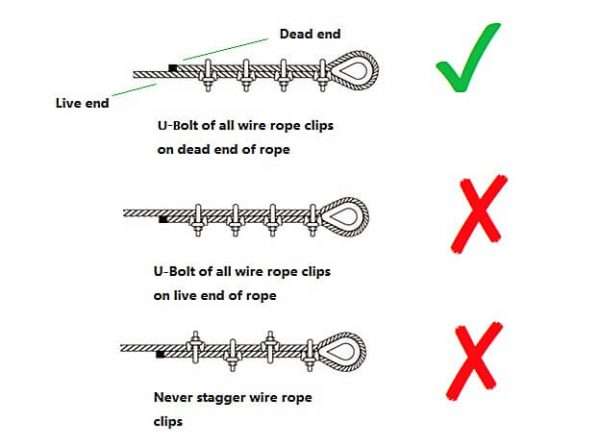

- The direction of Wire rope clips is shown in the figure above. The U-bolt of the rope clip is buckled at the end of the wire rope (that is, the side of the rope head), and the clamping seat is at the working section. All rope clips are in the same direction and must not be staggered.

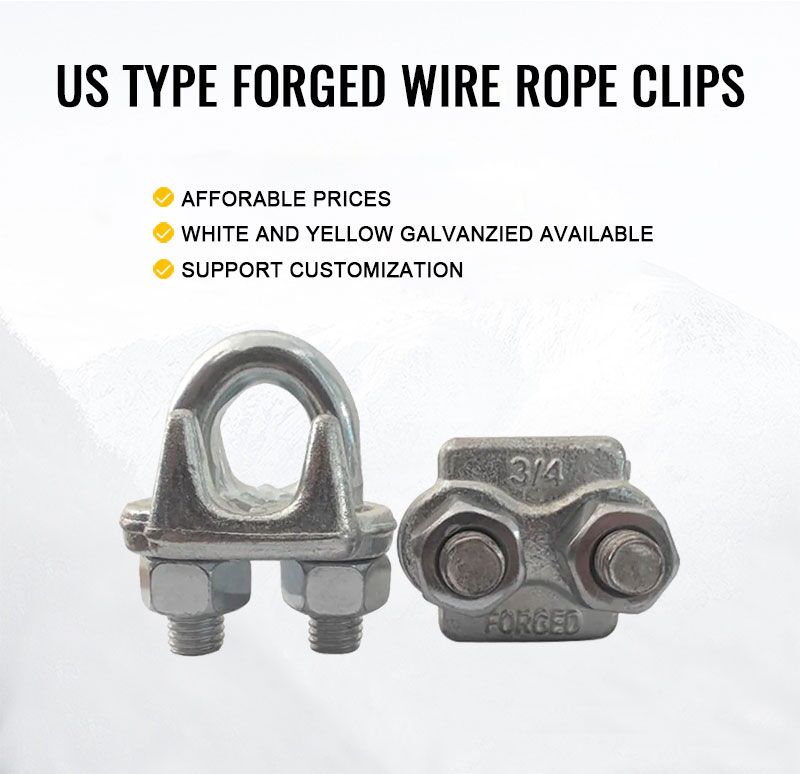

Types of wire rope clips/Types of wire clamps

Wire rope clips come in two primary variants: U-bolt and double saddle. The U-bolt clips, widely prevalent, can be crafted from either forged or malleable metal. In contrast, double saddle clips, though distinct, must not be utilized for overhead lifting applications due to safety considerations.

Wire Rope Clips Installation

The wire rope clip connection method generally uses the collet fixing method. Three types of wire rope clips are commonly used: horse-riding type, pressing plate type, and fisting type. The horse-riding type has the strongest connection force and is the most widely used, followed by the pressing type. The fisting type easily damages the wire rope because it has no base and low connection force. Poor, therefore, only used in minor places.

How do you install wire rope clips?

Here are the basic steps for installing a wire rope clip:

- To form the eye, wrap the wire rope around the thimble and then turn back the appropriate amount of rope according to the manufacturer’s instructions.

- To properly secure the wire rope, start by placing the first wire rope clip at the end of the dead end, leaving one base width of space. Then, use a torque wrench to tighten the nuts on the wire rope clip.

- If you need to use a second clip, position it as near as possible to the eye loop or thimble. Use a torque wrench to tighten the nuts of the clip securely.

- If you need more than two clips, place them evenly between the first two to ensure even spacing.

Wire rope clips should pay attention to the following points when using:

- When using wire rope clips, the inner net distance of the U-shaped ring should be 1-3mm larger than the diameter of the wire rope. If it is too large, the buckle connection will not be tight, and accidents will quickly occur.

- When attaching the wire rope clips, tighten the bolts until the rope is flattened by 1/3 to 1/4 of its diameter, and after the rope is stressed, tighten the clamp bolts again to ensure that the joint is firm and reliable.

- The chucks of wire rope clips should be arranged in a straight line, and the U-shaped part should be in contact with the end of the rope and cannot be in connection with the main rope. If the U-shaped element is in touch with the main rope, after the main rope is crushed, it is easy to break the wire when it is stressed.

- To check whether the wire rope clips are reliable and whether the wire rope is slipping, another wire rope clip can be installed about 500mm behind the last wire rope clip, and the rope end can be released into a “safety bend.” In this way, when the wire rope of the joint slips, the “safety bend” is first straightened, and measures should be taken immediately.

How many wire rope clips to use

Using at least three clips is crucial when creating a prepared loop or thimble-eye termination for wire rope, especially for overhead lifting. It is important to note that all three clips must be installed with the saddle part on the live end of the rope to ensure maximum safety and security.

How many cable clamps on wire rope

Wire rope assemblies typically require a minimum of two to three wire rope clips to fasten the rope ends effectively. For applications involving loop or thimble-eye terminations, utilizing a minimum of three clips is recommended. These clips should be evenly spaced at approximately six wire rope diameters between each clip. This arrangement ensures a sufficient level of grip and stability, reinforcing the integrity of the connection.

Uses of wire rope clips

Wire rope clips are used in ports, engineering hoisting machinery, metallurgical and mining equipment, oil field derrick, port railway loading and unloading, forestry machinery, electrical equipment, sea, land transportation, engineering rescue, salvage of sunken ships, lifting of factories and mines.

Tips for Purchasing Wire Rope Clips

Material: The chosen material must demonstrate resistance to both corrosion and abrasion. Wire rope clips come in diverse materials and surface treatments, with carbon steel, cast malleable iron, and stainless steel being the three primary options. Among these, stainless steel wire rope clips are the most superior choice, offering exceptional durability and performance.

Use: Every substance possesses a unique set of advantages and disadvantages.