News

Aug . 29, 2023 14:12 Back to list

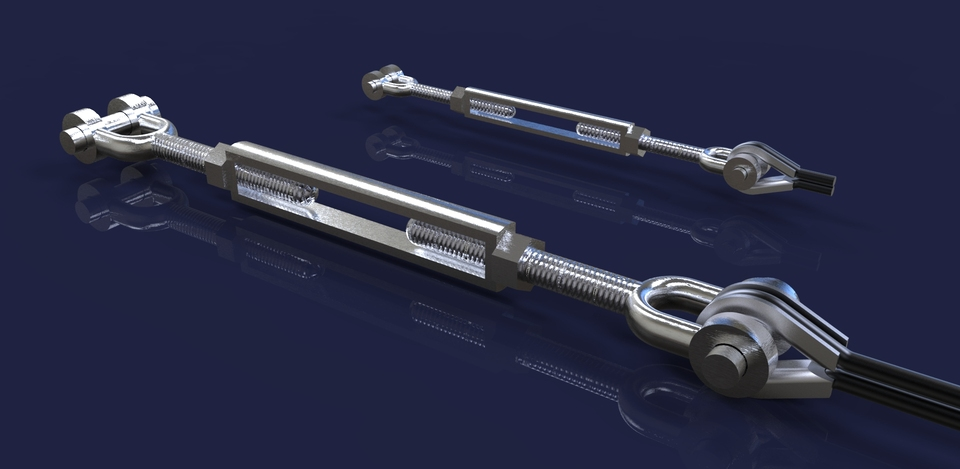

What Are the Basics of Turnbuckle Usage in the Field?

Materials

According to the ASME B30.26 Rigging Hardware standard, the hardware, excluding bushings and bearings, shall have sufficient ductility to permanently deform before losing the ability to support the load at the temperatures the manufacturer has specified for use.

Design Factor

Design factor is defined by the standard as the “ ratio between nominal or minimum breaking strength and rated load of the rigging hardware.”

According to the ASME B30.26 standard, the design factor for all adjustable hardware shall be a minimum of 5.

Rated Loads

A rated load is defined in the standard as “the maximum allowable working load established by the rigging hardware manufacturer. The terms ‘rated capacity’ and ‘working load limit’ are commonly used to describe rated load.”

Rated load shall be in accordance with the recommendation of the hardware manufacturer.

Proof Test Requirements

New adjustable hardware is not required to be proof tested unless specified by the purchaser.

All repairs to swivel hoist rings with bushings or bearings should be proof tested.

Proof-tested adjustable hardware shall be inspected after the test for the conditions stated in para. 26-2.8.5.

Proof Load Requirements

The proof load shall be a minimum of 2 times the rated load.

Operating Practices for Turnbuckles

Adjustable Hardware Selection

“Adjustable hardware having suitable characteristics for the type of load, hitch, angle of loading, and environment shall be selected in accordance with the recommendations of the adjustable hardware manufacturer or a qualified person.”

Additional Notes address the following:

The angle of loading affects the stress in the hardware. As the horizontal angle decreases, the stress increases.

The integrity of the load where the adjustable hardware attaches is the responsibility of the end user.

The rated load of the adjustable hardware shall not be exceeded.

Adjustable hardware that appears to be damaged shall not be used until inspected and accepted as usable.

Cautions to Personnel

To ensure a safe working environment for riggers and anyone else on the job site, ASME lists several things that should be addressed and / or monitored closely before, during, and after overhead lifts with adjustable hardware:

All portions of the human body shall be kept from between the rigging hardware, the load, and any other rigging during lifting or load-handling activities.

Personnel should stand clear of the suspended load.

Personnel should stand clear of rigging when it is under tension.

Personnel shall not ride rigging hardware.

-

Unveiling the Power of Wire Rope Clips

NewsJun.03,2025

-

Wire Rope Thimble: The Smart Solution for Maximum Cable Longevity

NewsMay.09,2025

-

Tension Made Elegant: Discover the Strength of Stainless Steel Turnbuckle

NewsMay.08,2025

-

Secure Strength Redefined: Explore the Power of DIN 580 Lifting Eye Bolt

NewsMay.08,2025

-

Marine-Grade Strength and Versatility: Why Stainless Steel Quick Link Is Your Ultimate Connector

NewsMay.08,2025

-

Double Barrel Crimps: The Secure Choice for Durable Wire Rope Fittings

NewsMay.08,2025