Are you planning to take up a large-scale building project or heavy lifting job? Consider bringing on a crane to help move and handle heavy loads. Cranes have advanced over the years and emerged as an invaluable asset in projects or worksites that involve heavy hauling. Without these versatile, sturdy machines, the construction of modern marvels like high-rises, skyscrapers, and bridges would be next to impossible.

The numerous crane types in the current market can leave you racking your brain over which one to use. The cranes also need the right rigging equipment to hoist items during projects securely. Correctly identifying the different types of rigging gear you may encounter will help you find compatible hardware for your rigging tasks. Here is an extensive insight into crane rigging and the different types of rigging equipment you need for a safe and successful project.

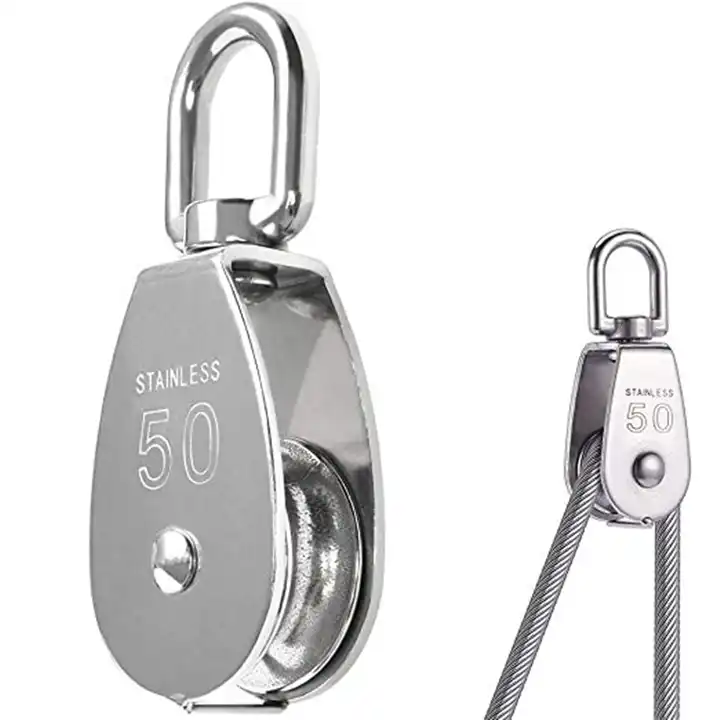

Wire Rope Pulley

What Is Crane Rigging

Rigging and lifting are terms often used interchangeably when handling heavy equipment like cranes. They actually have different meanings but ultimately complement each other in achieving a single goal.

So, what is rigging? Crane rigging refers to the safe securing of a load using different pieces of equipment before a lift. Lifting often follows rigging, as it involves the hoisting and movement of the load to any way around the worksite.

What Are the Responsibilities of a Crane Rigger?

A rigger sets up or prepares construction sites, worksites, warehouses, or any other location where heavy hauling occurs. Some of the key responsibilities they’re in charge of include the following:

- Creating a rigging plan

- Being involved in worksite preparation

- Anchoring and aligning machinery

- Adding and attaching loads

- Coordinating the movement of heavy machinery using hand signals

- Complying with the Occupational Safety and Health Association’s (OSHA) and American Society of Mechanical Engineers’ (ASME) regulations

- Calculating the weight of loads

How Do You Determine the Rigging Weight?

Before setting up your rigger, you may have to determine the weight of your load to ensure a safe lift. Luckily, there are situations when you don’t have to calculate the load’s weight. For instance, you can easily take weight readings on an industrial scale or read the information from design plans and engineering blueprints.

Sometimes, the load comes marked with its weight, or the manufacturer provides the weight specs on catalog data. If the weight isn’t provided, try using the following basic calculations to determine it.

Establish the Load’s Volume

The formula for calculating the volume of any object varies depending on its shape. For cuboidal and cube-shaped loads, multiply the length, width, and height. In the case of a hollow cylinder, multiply the area of its circular base by the height. For a complex shape, envision the entire load as a solid cuboid, then calculate its volume.

Confirm the Type of Material Your Lifting

Different materials have varying molecular compositions and different weights despite having the same volume. Industrial charts provide readings in pounds per cubic foot of materials you may encounter when rigging. Aluminum, for instance, weighs 165 pounds per cubic foot, while iron casting weighs 450 pounds per cubic foot.

Read the Load’s Weight

To get the final weight, multiply the volume found by the pound per cubic foot reading. Crane riggers can also mount dynamometers or load cells on the rigging equipment to read out the load’s weight. The appliance has a hydraulic pressure or strain gauge that translates the tension the load elicits into a weight reading.

What Are the Best Rigging Safety Practices?

In addition to calculating the load’s weight, other rigging practices promote worksite safety. These include the following.

Inspecting Your Rigging Gear

How often should you inspect your rigging plan? ASME and OSHA have different standards regarding inspecting and replacing worn-out rigging equipment. Performing a visual inspection upon receiving the gear is a recommended practice. Counter-check the hardware’s markings or tags to ensure the stated capacity meets your project’s lifting needs and specifications.

You can also have an expert rigger perform daily or pre-use assessment of the gear to check for any new defects or deformities. ASME and OSHA require documented periodic evaluation of rigger equipment after a year of use. You may need monthly or quarterly inspections of slings, wire ropes, and hooks, depending on:

- Severity of service conditions

- Frequency of use

- Load handling activities or nature of lifts

- Experience you acquire on the service life of rigging equipment used in similar tasks

Choosing Rigging Gear Based on Working Load Limit and Rating

The Working Load Limit (WLL) refers to the heaviest weight your rigging equipment can carry. The rigging components need equal strength of material to provide equal WLL readings. Your rigging gear is only as secure as your lowest or weakest WLL link. Ensuring all the parts of your configuration match the weight reading of the task at hand is an excellent practice to adopt.

Determining the Proper Sling Type and Hitch Configurations to Adopt

An expert rigger can easily identify the ideal sling type and hitch configuration for the job at hand. The different types of load support and connections you can choose from include:

- The vertical hitch. In this configuration, the rigger attaches the hook to one end of the sling and the other to the load. Using a vertical hitch, you can utilize the sling’s full hauling capacity. Consider using more than one sling in this situation, as a single sling can start rotating or twisting while lifting. Also, avoid using the vertical hitch when lifting a long material, unbalanced loads, or loose materials.

- The choker hitch. In this method, the crane rigger wraps the sling around the load before tightly securing it in place. This configuration is ideal for lifting large cylindrical objects. Adding blocks of wood between the hitch and load improves the angle and grip of the choke. However, you can only lift them one at a time as loose bundles easily dislodge despite the fastening.

- The basket hitch. In this technique, the rigger secures each end of the sling on the crane’s rigging hook. The configuration cradles the load, preventing any additional tension. You can opt for a double or single wrap sling configuration depending on the type and size of the load.

- The double wrap choker hitch. Using this configuration, the crane rigger can achieve 360° of contact around the load. The hitch essentially compresses or chokes the loaded components together, effectively preventing them from slipping out.

Determining the Ideal Sling Angle

A seasoned crane rigger understands that a change in sling angle alters the maximum stress limits. During a 90° or vertical lift, the weight is equally distributed on the slings. For instance, when lifting a 500-pound weight in a dual configuration, each sling supports 250 pounds. When the lifting angle reduces to 60°, 45°, or 30°, the weight distribution changes, and the sling’s effectiveness decreases. A rigging chart can help you determine your sling’s capacity at any given angle.

What is Rigging Equipment Hardware?

Rigging hardware refers to the different equipment used to lift and move loads in a crane system securely. It also includes the tools used to distribute the weight of the load evenly while hoisting. There are many different types of crane rigging equipment. Each kind of equipment is used in various applications, like construction and event management.

The different crane rigger equipment helps to hold and distribute the weight of heavy loads during the lifting process. The lifting machines that can handle these heavy loads include carry decks, crawler cranes boom lifts, and hydraulic trucks available for rent at Maxim Crane. Lifting and rigging gear is commonplace in construction, transportation, shipping, manufacturing, event staging, and more.

There are many rigging tools used to hoist items during construction projects and to make carrying loads possible. Proper rigging is a critical component of a successful crane operation and should always be done by a professional, so it’s important to make sure you have the right equipment for your project.

Tips for Using the Right Rigging Hardware

In the lifting and rigging industry, the right equipment not only means that the work is done efficiently but also everyone is kept safe on the site.

Before you decide which rigging equipment is the best for your project, a few things to consider are:

- The environment and weather of your site: Some rigging equipment may not be the best in certain climates, such as extreme cold, heat, or salty environments. For example, projects around saltwater bodies may require stainless steel hardware to guard against rust.

- The quality of the rigging materials: inexpensive rigging hardware can cost you more long term. You’ll need to get your equipment from reputable sources to ensure that your site is safe and the hardware doesn’t wear out too quickly.

- The materials you’re lifting and load limits: Every rigging hardware comes with a working load limit, which is the heaviest weight that it can handle safely without malfunction. You’ll need to know how heavy your load is to ascertain that all hardware you get can handle it.

Knowing the terminology of different types of crane rigging equipment will ensure you have the right kind for your project. Here are some of the most commonly used rigging hardware.

Types of Crane Rigging Hardware

Eye Bolts & Steel Nuts

Eyebolts are used as anchor points or for looping cables in rigging systems. There are two types of eye bolts: shouldered bolts and non-shouldered bolts, which are also known as straight bolts. Shouldered bolts are primarily used when loading at an angle, while non-shouldered eye bolts are used in a vertical rig system.

The type of eye bolt used depends on:

- The weight of the load

- The type of sling used

- The angle of loading, whether inline or at an angle

- The frame on which the bolt is secured to a material such as wood, metal, etc.

Stainless steel nuts are used together with eye bolts. There are various nuts used in rigging, including wing nuts, dome nuts, ball ends, and hex nuts. The type of nuts used also depends on the thread, which can be either right-hand or left-hand. The total weight of the load will determine the size of the steel nut used.

Rigging Hooks

Rigging hooks are made to lift heavy objects without slipping. They are typically made from forged alloy steel.

Some types of rigging hooks include:

- Sorting hooks

- Choker hooks

- Clevis grab

- Eye hooks

Depending on the materials being moved, the rigging hooks are selected based on their weight load indication and hook opening size, also known as the throat. Hook opening sizes range from 5/8 inch to 1 17/32 inch.

Other factors that determine the choice of rigging hooks include:

- The angle of the lift

- The weight of the materials lifted

- The connection points on the top and bottom of the hook

- The type of shackles used

The hooks can be used either as a lifting hook, hoist hook, or sling hook. While using hooks, especially the hoist hook, it is essential to check for cracks, bending, and other signs of strain to prevent further damage and accidents.

Wire Ropes

Wire rope is an incredibly durable and highly resistant cable used in rigging. There are plenty of sizes and configurations of wire rope made from different materials. Wire rope is made up of a core with wires and strands coiled in a spiral pattern around the core.

The strength and use of steel wire rope vary by:

- The diameter of the rope

- The material used for the wire rope’s core

- The grade of steel used

- The type of wire finish used, whether galvanized, bright steel, or stainless steel

- The number of strands used

Standard wire rope sizes include 6×19, 6×36, 6×26, 7×7, and 7×19.

Wire ropes are typically used with other rigging accessories such as clips, thimbles, sleeves, stops, and slings. Although wire rope is built for outdoor use, it still needs to be regularly inspected for wear, corrosion, and broken wires.

Spreader Bars and Lifting Beams

Lifting beams and spreader bars — also known as spreader beams — are used to connect the crane and the load. The main difference between the two is that lifting beams carry all the weight from a single point, while spreader beams spread the load over a wider area.

Lifting beams are used to carry lighter loads or weak ones that require additional support. They are often thicker and heavier than spreader bars since they take all the pressure at one connection point and can easily bend.

Spreader bars are used to make carrying loads more manageable and stable by distributing the load on multiple connection points. They are often brought in when the load is too heavy to be lifted from one connection point. They are connected to the rigging equipment using a sling.

Pulleys & Blocks

Pulleys and blocks are a staple for lifting very heavy weights. They help to move hefty objects without using excessive force. Your choice of pulley depends on the rope you’re using, the frame type, and the sheave size.

There are several types of lifting blocks as well, including:

- Swivel blocks

- Square blocks

- Tilt-up blocks

- Snatch blocks

Pulleys can be used either as a single or double system. The system works by circling the pulleys with rigging ropes, which are then hooked to the objects to lift.

Different types of rigging ropes are used based on the weight of the materials. Wire rope is typically attached to the lifting blocks. This is because lifting blocks usually carry more weight which the wire ropes handle well. Synthetic rope is commonly used with pulleys. Blocks and pulleys come in a broad spectrum of sizes capable of lifting and moving up to 30 tons.

Other Types of Rigging Hardware

There is still plenty of other rigging hardware you’d expect to see on a site.

These include:

- Shackles: These are used to connect chains, ropes, or slings to each other or a load.

- Synthetic slings: Synthetic slings are lightweight, flexible lifting slings used to grip and hoist various loads.

- Turnbuckles: Turnbuckles are used to adjust the tension on a rope, chain, or other rigging equipment with tension.

- Tie-down straps: These are used to safely secure the load being transported or lifted.

Rigging Hardware Safety

Since rigging involves carrying heavy loads, it must be done in the safest way possible to avoid causing accidents.

Some safety tips you can use when using rigging hardware include:

- Only use rigging equipment that is in proper condition. Cracks, bends, stretches, and missing parts reduce the safety of the equipment and increase the risk under heavy loads. Any faulty equipment should be repaired or replaced before using the rig.

- Use the equipment according to the manufacturer’s specifications. Each rigging hardware has its specifications, such as the maximum weight it can bear, the right angles to use them, and how to connect them to the lifting equipment. Ensure that you follow the manufacturer’s instructions in the crane rigging charts as you use them.

- A professional should regularly inspect the equipment before use. If the hardware requires servicing, it should also be done promptly to ensure the equipment runs smoothly and lasts longer.

- Avoid working under a suspended load or leaving anything suspended on the rig.

- Ensure that the load is well secured and balanced on the rigging equipment to keep it from tipping, rotating, or falling.