News

Aug . 17, 2024 11:55 Back to list

Turnbuckle Production and Supply by Leading Rigging Manufacturers Across the Industry

The Importance of Selecting the Right Rigging Turnbuckle Manufacturer

When it comes to rigging and lifting operations, the importance of choosing the right turnbuckle manufacturer cannot be overstated. Turnbuckles are essential components that adjust tension and length in cable systems, making them integral to ensuring safety and reliability in various applications, from construction sites to maritime operations. In this article, we will explore the factors to consider when selecting a rigging turnbuckle manufacturer and the advantages of working with a reputable source.

Understanding Turnbuckles and Their Role

A turnbuckle consists of a metal frame with two threaded end fittings, allowing for the adjustment of tension on a wire rope or cable. This simple yet effective design allows users to achieve the necessary tension in rigging applications, making it a favorite among riggers, engineers, and contractors. Turnbuckles come in varying sizes and materials, adaptable to different environments and load requirements.

Factors to Consider When Selecting a Turnbuckle Manufacturer

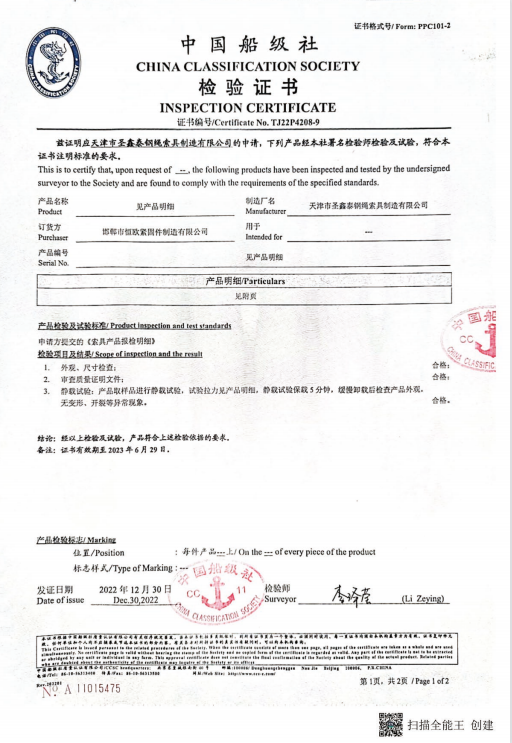

1. Quality Assurance One of the primary considerations when choosing a rigging turnbuckle manufacturer is their commitment to quality. It is essential to select a manufacturer that adheres to stringent industry standards and certifications. A trusted manufacturer will often provide details about their quality control processes and the materials used in production. Look for manufacturers that comply with regulations such as ASTM, ISO, or other relevant standards to ensure the product's durability and reliability.

2. Range of Products A reputable turnbuckle manufacturer will offer a wide range of products to accommodate various applications and specifications. This includes different sizes, materials (such as stainless steel, galvanized steel, or aluminum), and configurations (such as open body or closed body). Having a broad selection allows customers to find the most suitable option for their specific needs.

rigging turnbuckle manufacturer

3. Innovative Designs The engineering industry is continuously evolving, and innovative designs can improve safety and ease of use. Choose a manufacturer that invests in research and development, offering advancements in turnbuckle technology that enhance performance and prolong service life.

4. Customization Options Depending on your project requirements, you may need customized turnbuckles. A manufacturer that provides bespoke solutions can create turnbuckles tailored to your exact specifications, ensuring optimal performance in your unique application.

5. Reputation and Experience The manufacturer’s reputation in the industry speaks volumes about their reliability. Research their history, customer reviews, and past projects. An experienced manufacturer with positive feedback is more likely to deliver high-quality products consistently.

6. Customer Support and After-Sales Service Strong customer support is crucial for resolving any issues that may arise post-purchase. A manufacturer that offers comprehensive support, training, and reliable service can be a valuable partner throughout the product lifecycle.

Conclusion

Choosing the right rigging turnbuckle manufacturer is a critical decision that impacts the safety and efficiency of your operations. By considering factors such as quality assurance, product range, innovation, customization, reputation, and customer support, you can ensure that you select a manufacturer that meets your needs. Investing time in this selection process ultimately contributes to enhanced safety, reliability, and performance in your rigging applications. Whether you are in construction, manufacturing, or marine industries, partnering with a reputable turnbuckle manufacturer will pave the way for successful project execution and peace of mind.