News

Aug . 05, 2024 22:22 Back to list

Top Eye Bolt Manufacturers and Suppliers in the Market for Reliable Industrial Hardware

The Importance of 1% 204% Eye Bolt Companies in Industrial Applications

In the world of industrial manufacturing and construction, various components play a critical role in ensuring safety and reliability. Among these components, eye bolts serve as essential fasteners used to attach and secure loads. While eye bolts themselves come in different designs and materials, companies that specialize in manufacturing high-quality eye bolts, such as those categorized within the 1% 204% spectrum, are crucial for maintaining operational safety and efficacy in various fields.

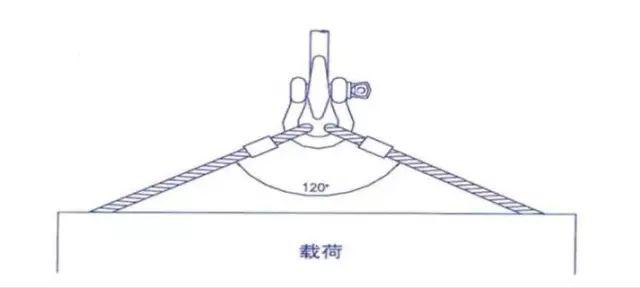

Understanding Eye Bolts

An eye bolt is a type of fastener that features a looped head, allowing it to be connected to a chain or rope. Its design provides a reliable point for lifting heavy objects or securing loads. Eye bolts are commonly used in construction, shipping, and mechanical engineering, where they play a vital role in lifting systems and load stabilization. The specifications and quality of these fasteners can significantly influence safety standards in any project.

The Role of 1% 204% Eye Bolt Companies

The 1% 204% classification refers to a specific reliability and quality standard that these eye bolt companies adhere to. This designation is not merely a figure; it symbolically represents the companies that comply with rigorous testing protocols and stringent manufacturing practices. Such manufacturers ensure that their eye bolts can withstand significant loads while minimizing failure risks.

These companies often invest in advanced metallurgy and production techniques to produce high-strength eye bolts that can endure extreme conditions. They might also focus on corrosion resistance, particularly for products intended for marine or mountainous environments. Therefore, partnering with a reputable 1% 204% eye bolt company ensures that the fasteners used in projects are up to industry standards and can be relied upon in critical situations.

1 4 eye bolt companies

Quality Assurance and Certification

For buyers and project managers, seeking out 1% 204% eye bolt companies not only guarantees quality products but also comes with the assurance of certifications. These certifications often include compliance with national and international safety and quality standards, such as ISO or ASTM. Such credentials are vital, especially in projects where miscalculations or failures can lead to costly damages or hazardous situations.

Innovations in Eye Bolt Manufacturing

As industries evolve, so does the manufacturing technology surrounding eye bolts. Companies dedicated to this niche continually research and implement innovative solutions to enhance the effectiveness and durability of their products. This can include the use of new materials, such as high-strength composite materials, which offer improved performance while being lightweight. Additionally, advancements in coating technologies can provide better protection against environmental factors, prolonging the lifespan of the eye bolts.

Conclusion

The importance of engaging with 1% 204% eye bolt companies cannot be understated in the realms of construction and manufacturing. The reliability of these fasteners directly correlates with the safety and success of the projects they support. By choosing companies that adhere to rigorous standards and continually innovate their manufacturing processes, businesses can ensure that they are using top-tier eye bolts that meet the demands of their respective applications. As industries continue to expand and evolve, the development and enhancement of eye bolt technology will remain pivotal in securing the future of safe and effective load management. Ultimately, investing in quality eye bolts from reputable manufacturers is a necessary step towards achieving both safety and efficiency in any project.