News

Jul . 05, 2024 00:40 Back to list

Service for Jaw and Jaw turnbuckles Enhancing functionality and extending lifespan

When it comes to maintaining a well-functioning jaw and jaw turnbuckle, regular service and inspection are crucial. These components are essential for many applications, including construction, marine, and industrial equipment.

The jaw is a critical component that forms part of a hinge or a latch and is responsible for connecting two parts or objects. It is typically made of strong and durable material to withstand heavy loads and frequent use. The jaw provides stability and support, allowing for smooth movement and operation of the connected components.

The jaw turnbuckle, on the other hand, is a type of fastener used to adjust tension or length in rigging systems. It consists of two threaded eye bolts connected by a body, which can be turned to either increase or decrease tension. The jaw turnbuckle is commonly used in applications where precise adjustment of tension is required, such as in sailboat rigging or construction scaffolding.

Regular service and inspection of both the jaw and jaw turnbuckle are necessary to ensure their proper functioning and longevity. During service, the components should be cleaned, lubricated, and inspected for any signs of wear or damage. Any worn or damaged parts should be replaced immediately to prevent accidents or malfunctions Any worn or damaged parts should be replaced immediately to prevent accidents or malfunctions Any worn or damaged parts should be replaced immediately to prevent accidents or malfunctions Any worn or damaged parts should be replaced immediately to prevent accidents or malfunctions

Any worn or damaged parts should be replaced immediately to prevent accidents or malfunctions Any worn or damaged parts should be replaced immediately to prevent accidents or malfunctions jaw and jaw turnbuckle service.

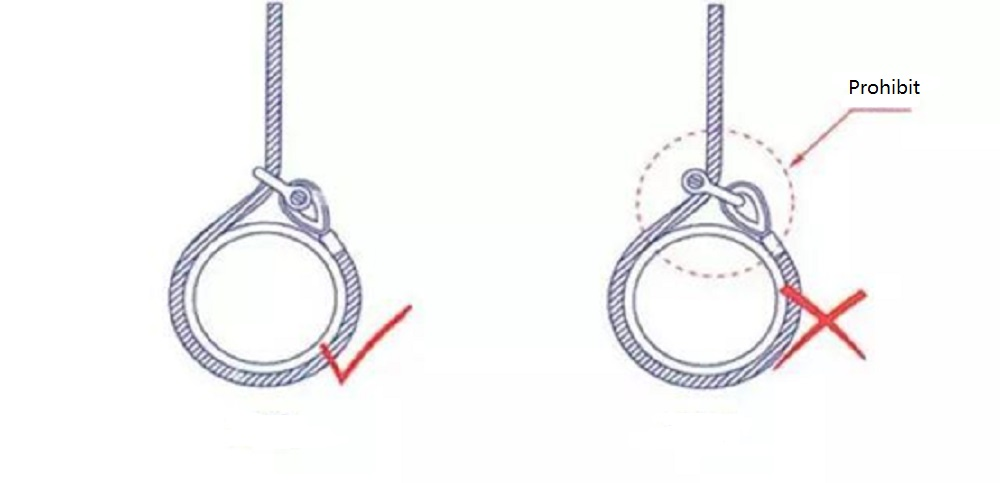

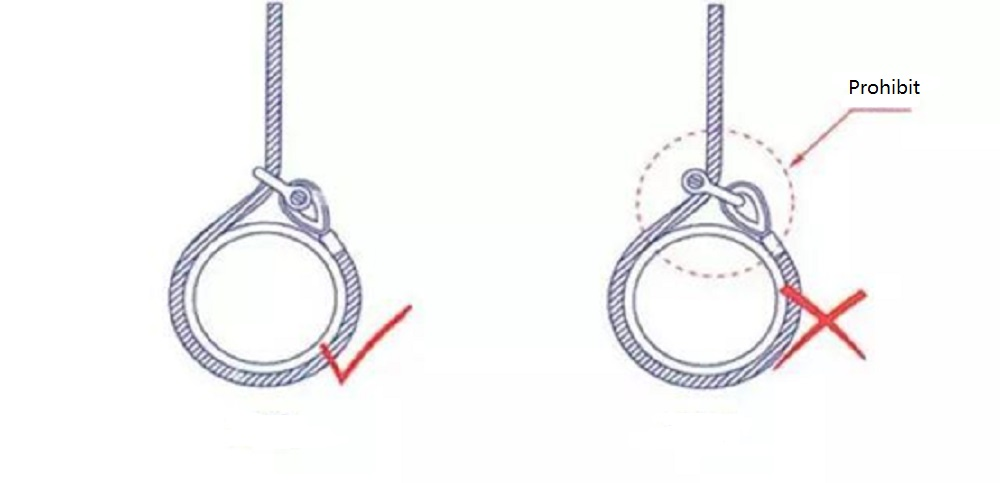

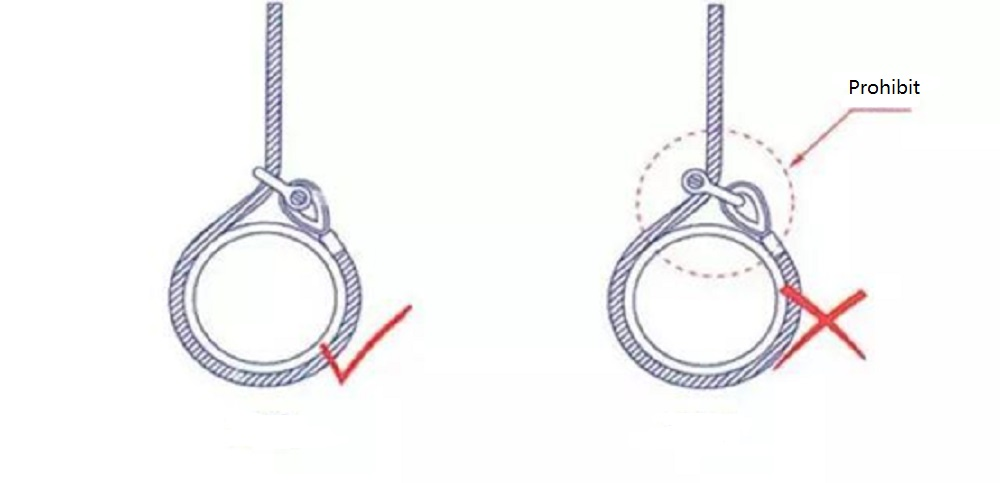

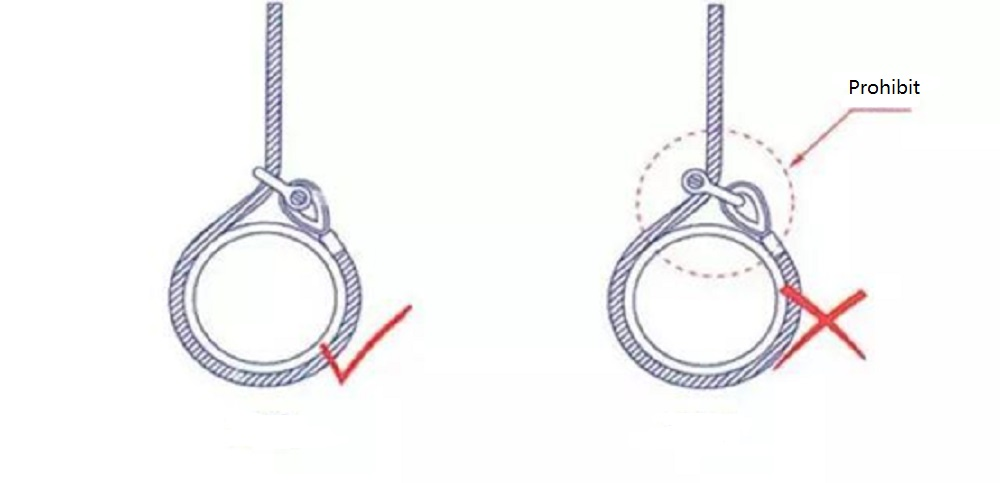

Proper maintenance of the jaw and jaw turnbuckle also involves checking for proper alignment and tension. Misalignment or improper tension can lead to premature wear and failure of the components. Regular inspection can help identify any issues early on and prevent more extensive damage down the line.

In addition to regular service, it is essential to follow the manufacturer's guidelines for care and maintenance of the jaw and jaw turnbuckle. These guidelines may include specific lubrication requirements, torque settings for fasteners, or inspection intervals. By following these recommendations, you can ensure the optimal performance and lifespan of your equipment.

Ultimately, proper care and maintenance of the jaw and jaw turnbuckle are essential for the safety and efficiency of your equipment. By investing time and effort into regular service and inspection, you can avoid costly repairs or replacements and extend the lifespan of your components. So, don't overlook the importance of caring for your jaw and jaw turnbuckle – your equipment will thank you for it.

jaw and jaw turnbuckle service.

Proper maintenance of the jaw and jaw turnbuckle also involves checking for proper alignment and tension. Misalignment or improper tension can lead to premature wear and failure of the components. Regular inspection can help identify any issues early on and prevent more extensive damage down the line.

In addition to regular service, it is essential to follow the manufacturer's guidelines for care and maintenance of the jaw and jaw turnbuckle. These guidelines may include specific lubrication requirements, torque settings for fasteners, or inspection intervals. By following these recommendations, you can ensure the optimal performance and lifespan of your equipment.

Ultimately, proper care and maintenance of the jaw and jaw turnbuckle are essential for the safety and efficiency of your equipment. By investing time and effort into regular service and inspection, you can avoid costly repairs or replacements and extend the lifespan of your components. So, don't overlook the importance of caring for your jaw and jaw turnbuckle – your equipment will thank you for it.

Any worn or damaged parts should be replaced immediately to prevent accidents or malfunctions Any worn or damaged parts should be replaced immediately to prevent accidents or malfunctions

Any worn or damaged parts should be replaced immediately to prevent accidents or malfunctions Any worn or damaged parts should be replaced immediately to prevent accidents or malfunctions jaw and jaw turnbuckle service.

Proper maintenance of the jaw and jaw turnbuckle also involves checking for proper alignment and tension. Misalignment or improper tension can lead to premature wear and failure of the components. Regular inspection can help identify any issues early on and prevent more extensive damage down the line.

In addition to regular service, it is essential to follow the manufacturer's guidelines for care and maintenance of the jaw and jaw turnbuckle. These guidelines may include specific lubrication requirements, torque settings for fasteners, or inspection intervals. By following these recommendations, you can ensure the optimal performance and lifespan of your equipment.

Ultimately, proper care and maintenance of the jaw and jaw turnbuckle are essential for the safety and efficiency of your equipment. By investing time and effort into regular service and inspection, you can avoid costly repairs or replacements and extend the lifespan of your components. So, don't overlook the importance of caring for your jaw and jaw turnbuckle – your equipment will thank you for it.

jaw and jaw turnbuckle service.

Proper maintenance of the jaw and jaw turnbuckle also involves checking for proper alignment and tension. Misalignment or improper tension can lead to premature wear and failure of the components. Regular inspection can help identify any issues early on and prevent more extensive damage down the line.

In addition to regular service, it is essential to follow the manufacturer's guidelines for care and maintenance of the jaw and jaw turnbuckle. These guidelines may include specific lubrication requirements, torque settings for fasteners, or inspection intervals. By following these recommendations, you can ensure the optimal performance and lifespan of your equipment.

Ultimately, proper care and maintenance of the jaw and jaw turnbuckle are essential for the safety and efficiency of your equipment. By investing time and effort into regular service and inspection, you can avoid costly repairs or replacements and extend the lifespan of your components. So, don't overlook the importance of caring for your jaw and jaw turnbuckle – your equipment will thank you for it. Share