News

Dec . 07, 2024 06:57 Back to list

rigging accessories supplier

Understanding Rigging Accessories and Their Importance in Various Industries

In the world of heavy equipment and construction, the term rigging refers to the process of lifting and moving heavy loads through a combination of mechanical devices and supporting devices. A crucial part of this process is the use of rigging accessories, which enhance safety, efficiency, and effectiveness in various applications.

What Are Rigging Accessories?

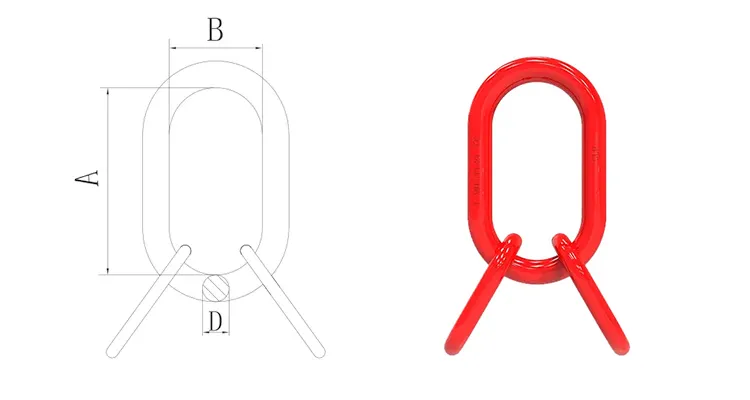

Rigging accessories encompass a wide range of components used in lifting and rigging applications. These accessories include items such as shackles, hooks, slings, chains, pulleys, and thimbles. Each of these components plays a specific role in ensuring that lifts are conducted safely and securely. For instance, shackles are often used to connect the load to the lifting apparatus, while slings distribute the load's weight evenly, reducing the risk of accidents.

The Role of Rigging Accessories Suppliers

Rigging accessories suppliers play a crucial role in the industry by providing high-quality components that meet safety standards and industry regulations. These suppliers source their materials from reputable manufacturers, ensuring that every item is tested and certified for performance. When choosing a supplier, it's vital to consider their experience, product range, and reputation within the industry.

A reliable rigging accessories supplier should be able to offer a variety of products tailored to meet the specific needs of different applications. For instance, industries such as construction, shipping, and entertainment require various types of rigging equipment designed to handle unique challenges. Hence, a one-size-fits-all approach rarely suffices.

Key Considerations When Selecting Rigging Accessories

1. Load Capacity One of the primary considerations when selecting rigging accessories is understanding the load capacity required for the project. Each accessory has a specified weight limit, and it is essential to choose components that can safely handle the intended load.

rigging accessories supplier

2. Material Type Rigging accessories can be made from various materials, including steel, alloy, and synthetic materials. The choice of material often depends on the environment in which they will be used. For instance, stainless steel accessories are frequently chosen for marine applications due to their corrosion resistance.

3. Compliance with Standards Safety is paramount in rigging applications. It is crucial to ensure that all accessories conform to the relevant regulations and standards set by organizations such as the Occupational Safety and Health Administration (OSHA) or the American National Standards Institute (ANSI).

4. Inspection and Maintenance Regular inspection and maintenance of rigging accessories are essential for ensuring longevity and safety. Suppliers should provide guidelines on how these accessories should be maintained and suggest frequency for inspections.

Innovations in Rigging Accessories

As technology evolves, so do rigging accessories. Innovations such as RFID technology embedded in shackles and other components allow for better tracking and management of equipment. These advancements help improve safety by providing real-time data regarding the condition and usage of rigging components.

Additionally, manufacturers are investing in lighter yet stronger materials, improving ease of use without compromising safety. The development of specialized slings, designed for specific applications, also showcases how innovation continues to enhance the capabilities of rigging accessories.

Conclusion

In conclusion, rigging accessories are vital for ensuring safe and efficient lifting operations across various industries. With the right accessories, companies can significantly enhance their operational efficiency while minimizing risks. Selecting a reliable rigging accessories supplier is essential, as the quality of equipment directly impacts workplace safety and productivity. Companies should prioritize understanding their requirements, adhering to safety standards, and embracing innovations that can drive their operations forward. As industries continue to grow, the role of quality rigging accessories becomes ever more critical, underlining the importance of superior suppliers in this essential market.