News

Nov . 24, 2024 08:31 Back to list

manufacturer european style shackle

Manufacturer European Style Shackle An Insight into Design and Functionality

The world of manufacturing is replete with a diverse array of components, each playing a crucial role in various industries. Among these components, the European style shackle stands out for its unique design and functionality. This article delves into the key aspects of manufacturer European style shackles, exploring their significance, design elements, applications, and the future of their usage in different sectors.

Understanding the European Style Shackle

A shackle, in its most basic form, is a U-shaped device used to connect two or more components. Shackles are often employed in rigging, hoisting, and lifting applications, where heavy loads need to be securely held and manipulated. The European style shackle, characterized by its robust construction and precise engineering, is widely recognized for its reliability and safety features.

Manufacturers of European style shackles prioritize quality and innovation to meet the stringent safety standards that the industry demands. These shackles are typically made from high-strength materials such as alloy steel or stainless steel, ensuring durability and resistance to corrosion, which is particularly important in marine or humid environments.

Design Features

European style shackles often exhibit several distinctive design features that enhance their performance. One of the most recognizable characteristics is the pin mechanism. The pin, which can be either a screw pin or a bolt-type pin, secures the shackle and helps to prevent accidental disconnection. Many manufacturers incorporate safety features such as safety latches or locking mechanisms, offering an extra layer of security during operations.

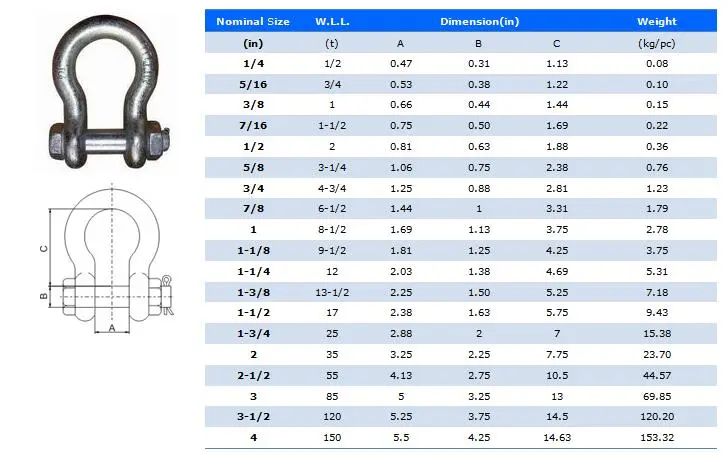

Another design element that sets European style shackles apart is their load rating specifications. These shackles are rigorously tested to ensure they can withstand specific weight limits while maintaining structural integrity. This attention to detail assures users that they can rely on these shackles in critical applications.

Applications in Various Industries

manufacturer european style shackle

European style shackles find extensive application across a myriad of industries. In the construction sector, they're essential for lifting heavy materials and securing loads during transport. Their capability to handle substantial weight makes them invaluable in cranes and hoisting systems.

In the maritime industry, shackles are used to connect ropes, chains, and other rigging elements. Their corrosion-resistant properties ensure they can endure harsh marine environments, making them ideal for shipyards and on vessels themselves. Additionally, in the oil and gas sector, these shackles are utilized in various lifting operations, guaranteeing safety and efficiency when dealing with heavy equipment and materials.

The manufacturing and transportation sectors also make extensive use of European style shackles. In manufacturing plants, they are used in assembly lines for lifting and securing heavy parts. When it comes to logistics, these shackles are essential for securing cargo during transportation, ensuring that loads remain stable and accidents are minimized.

Future Trends and Innovations

As technology evolves, manufacturers of European style shackles are continuously looking for ways to enhance their products. The incorporation of advanced materials, such as high-performance polymers or lighter alloys, is a notable trend. These materials offer similar levels of strength while reducing overall weight, making handling easier.

Smart shackle technology is also emerging, featuring integrated weight sensors and wireless capabilities. Such innovations enable real-time load monitoring, enhancing safety by alerting operators if a shackle is being overloaded.

Sustainability is another significant focus area for shackle manufacturers. Many are adopting eco-friendly practices and materials in their production processes, responding to the growing demand for environmentally responsible products.

Conclusion

The European style shackle is a vital component in various industries, embodying strength, safety, and innovation. As manufacturers strive to meet the evolving demands of diverse applications, these shackles continue to play an essential role in ensuring secure lifting and transportation of heavy loads. With advancements in design and technology, the future of European style shackles looks promising, poised to support industries while prioritizing safety and sustainability.