News

Aug . 13, 2024 23:24 Back to list

Leading Manufacturers of Rigging Chains for Heavy-Duty Applications and Reliable Performance Solutions

The Importance of Rigging Chains Manufacturers in the Industry

Rigging chains play a vital role in various industrial applications, from construction to shipping. As a crucial component of lifting and moving heavy loads, the quality and reliability of rigging chains are paramount. This is where rigging chains manufacturers come into play, ensuring that these essential tools meet safety standards and industry requirements.

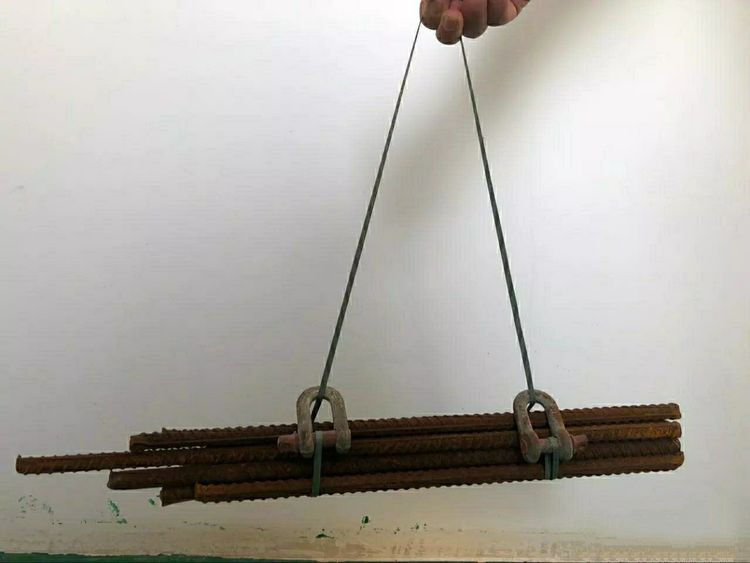

Understanding Rigging Chains

Rigging chains are specially designed steel chains used for lifting and moving heavy objects. These chains can withstand significant weight and are often used in conjunction with other equipment like hooks, hoists, and slings. There are various types of rigging chains, including alloy chains, welded links, and proof-tested chains, each serving different purposes and adhering to specific safety regulations.

The Role of Manufacturers

Rigging chains manufacturers are tasked with producing high-quality chains that meet rigorous standards. They utilize advanced technology and materials to ensure that the chains are not only durable but also safe to use in challenging environments. Manufacturers invest in research and development to innovate and improve existing products, ensuring compliance with both national and international safety regulations.

One of the critical factors that manufacturers focus on is the strength-to-weight ratio of the chains. A good manufacturing process will ensure that the chains can handle heavy loads without being excessively bulky, making them easier to use in various applications. Moreover, manufacturers often conduct rigorous testing of their chains, including tensile strength tests, fatigue tests, and environmental resistance tests, to guarantee their reliability.

Safety Standards and Regulations

rigging chains manufacturers

Rigging chains must comply with several safety standards, such as the American National Standards Institute (ANSI) and the Occupational Safety and Health Administration (OSHA) regulations. Manufacturers play a crucial role in ensuring that their products meet these standards to protect workers and prevent accidents. Regular inspections and certifications are essential to maintaining quality control and ensuring that chains are safe for use in the field.

With the rise of global commerce, the demand for rigging chains has surged. Manufacturers must adapt to different markets and comply with various local regulations, which can be a challenging task. However, reputable manufacturers often have the expertise to navigate these complexities, ensuring that their products are widely accepted around the world.

Custom Solutions

Another significant aspect of rigging chains manufacturers is their ability to offer tailored solutions to their customers. Industries often have unique requirements based on the specific loads they handle and the environments in which they operate. Manufacturers can create custom rigging chains to meet these specifications, providing added value to their clients.

Whether it’s adjusting the chain length, selecting particular coatings for corrosion resistance, or designing chains capable of handling specialized loads, customization is key to meeting customer satisfaction. This flexibility is what sets apart top manufacturers from others in the industry.

Conclusion

In conclusion, rigging chains manufacturers are an integral part of the industrial landscape, ensuring that businesses have access to reliable and safe lifting solutions. By adhering to strict safety standards, investing in innovative manufacturing technologies, and offering customized products, these manufacturers play a crucial role in enhancing workplace safety and efficiency. As industries continue to evolve, the demand for high-quality rigging chains will only increase, highlighting the importance of these manufacturers in driving safety and productivity across sectors.