News

Aug . 01, 2023 14:19 Back to list

How to use a turnbuckle?

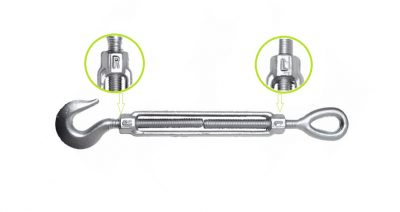

Usually, a turnbuckle pair for tightening the rigging is referred to as a basket screw. Due to the two forms of the bolt end structure that can be retracted at both ends, including a closed ring and a curved hook, it is vividly referred to as an OO type, CC type, or CO type basket screw. But in fact, the turnbuckle also refers to a special screw pair that has slots on each opposite side of one end of the nut, drills holes in the bolt head, tightens the nut, aligns the holes and slots, and inserts an opening to prevent the nut from loosening. The turnbuckle uses thread extension to adjust the tightness of steel wire ropes or other fastening ropes. In other operations, such as component transportation and cargo fastening, it plays a role in correcting looseness. Usually,turnbuckle consist of adjustable levers with left and right spiral patterns, as well as nuts and pull rods.

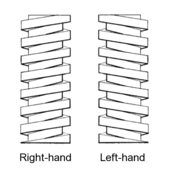

By common convention, most threads are the default for right-handed screw threads. Therefore, most threaded parts and fasteners have right-handed threads.

When seen from a point of view on the axis through the center of the helix, it moves away from you when it is turned in a clockwise direction and moves towards you when it is turned counterclockwise. This is known as a right-handed (RH) thread because it follows the right-hand grip rule. Threads oriented in the opposite direction are known as left-handed (LH).

So commonly you can see the letter “R” and ” L” on both turnbuckle body end.

Keep in mind of straightforward steps:

- First, unscrew end fittings from the turnbuckle body until completely extended to the full take-up length.

- Second, connect end fittings on either end to desired securement point, for eye end and hook end fittings, simply loop it through whatever securement point it will be connected to, as for jaw end fitting, unscrew the bolt from the jaw, place the securement point between the clevis ears (thimble, eye bolt, etc), then place the bolt through, and screw it shut.

- If you want to get more useful knowledge about how to use a turnbuckle, you can contact us by email at infohengou@gmail.com. We will be glad to share with you more useful information.

-

Turnbuckle Applications: Where Precision Meets Practicality

NewsAug.01,2025

-

Unveiling the Power of Wire Rope Clips

NewsJun.03,2025

-

Wire Rope Thimble: The Smart Solution for Maximum Cable Longevity

NewsMay.09,2025

-

Tension Made Elegant: Discover the Strength of Stainless Steel Turnbuckle

NewsMay.08,2025

-

Secure Strength Redefined: Explore the Power of DIN 580 Lifting Eye Bolt

NewsMay.08,2025

-

Marine-Grade Strength and Versatility: Why Stainless Steel Quick Link Is Your Ultimate Connector

NewsMay.08,2025