News

Aug . 11, 2024 14:00 Back to list

Exploring the Production Process of Rigging Shackles in Modern Manufacturing Facilities and Their Applications

The Importance of Rigging Shackle Factories in Modern Industry

In today's industrial landscape, the role of rigging shackle factories has become increasingly vital. These facilities specialize in the production of shackles, a fundamental component used in various lifting and rigging operations. Founded on principles of safety, durability, and innovation, rigging shackle factories contribute significantly to the efficiency and safety of construction, maritime, and various transportation industries.

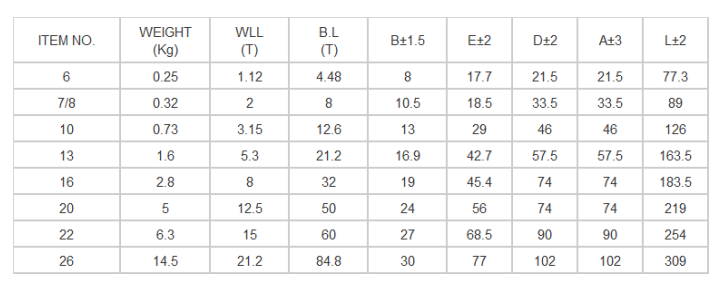

Shackles are U-shaped tools made of metal, primarily used to connect chains, ropes, and lifting devices. They come in various designs, including bolt-type, screw-pin, and safety shackles, each suited to specific applications. The versatility and reliability of shackles make them indispensable in operations ranging from heavy lifting on construction sites to securing loads in shipping and transport.

One of the primary responsibilities of rigging shackle factories is to ensure the quality and safety of their products. With heavy lifting and rigging involved, the stakes are high—failure of any rigging component can lead to catastrophic accidents, resulting in significant property damage and risk to human life. Therefore, these factories adhere to rigorous manufacturing standards and quality control processes. They typically utilize high-grade materials such as alloy steel, which is known for its strength and resistance to wear. Many factories implement stringent testing methodologies, including tensile tests and load testing, to ensure that every shackle can withstand its rated load before it leaves the production line.

Moreover, as industries evolve, so do the technologies used in rigging shackle production. Modern factories are increasingly incorporating automation and advanced manufacturing techniques, such as computer-aided design (CAD) and computer numerical control (CNC) machining. These technologies allow for precision engineering, resulting in products that not only meet but often exceed industry standards. Additionally, research and development teams in these factories work on innovating new designs and materials, enhancing the performance and capabilities of shackles.

rigging shackle factories

Environmental sustainability is another critical focus in contemporary rigging shackle factories. As industries face increasing pressure to reduce their carbon footprints, many manufacturers are adopting eco-friendly practices. This includes sourcing raw materials responsibly, minimizing waste during production, and implementing energy-efficient operations. Such initiatives are not only beneficial for the environment but can also lead to cost savings and a positive public image.

The global market for rigging shackles is also expanding, driven by the growth of various sectors, including construction, shipping, and manufacturing. As infrastructure projects proliferate and global trade increases, the demand for reliable rigging equipment is set to rise. This presents an opportunity for rigging shackle factories to expand their operations and develop new products tailored to dynamic market needs.

Furthermore, as safety regulations become more stringent across industries, the role of these factories in ensuring compliance is more critical than ever. They must stay abreast of regulatory requirements and industry best practices to maintain their competitive edge. This often involves collaboration with industry standards organizations to contribute to the formulation and refinement of safety guidelines.

In conclusion, rigging shackle factories play an essential role in modern industry, providing critical components that ensure the safety and efficiency of various operations. With a focus on quality, innovation, sustainability, and adherence to safety regulations, these factories are equipped to meet the growing demands of a diverse range of sectors. As industries continue to grow and evolve, the significance of rigging shackles, and the factories that produce them, will only increase.