News

Aug . 15, 2024 11:02 Back to list

Exploring the Most Notable Large Turnbuckles in Engineering and Construction Applications Today

The Importance of Turnbuckles in Heavy-Duty Applications

Turnbuckles are versatile mechanical devices widely used in various industries and applications. Renowned for their ability to provide tension and adjust the length of cables or rods, turnbuckles are essential components in the realms of construction, rigging, and marine operations. In this article, we explore the significance of famous large turnbuckles and their role in ensuring safety and functionality in heavy-duty applications.

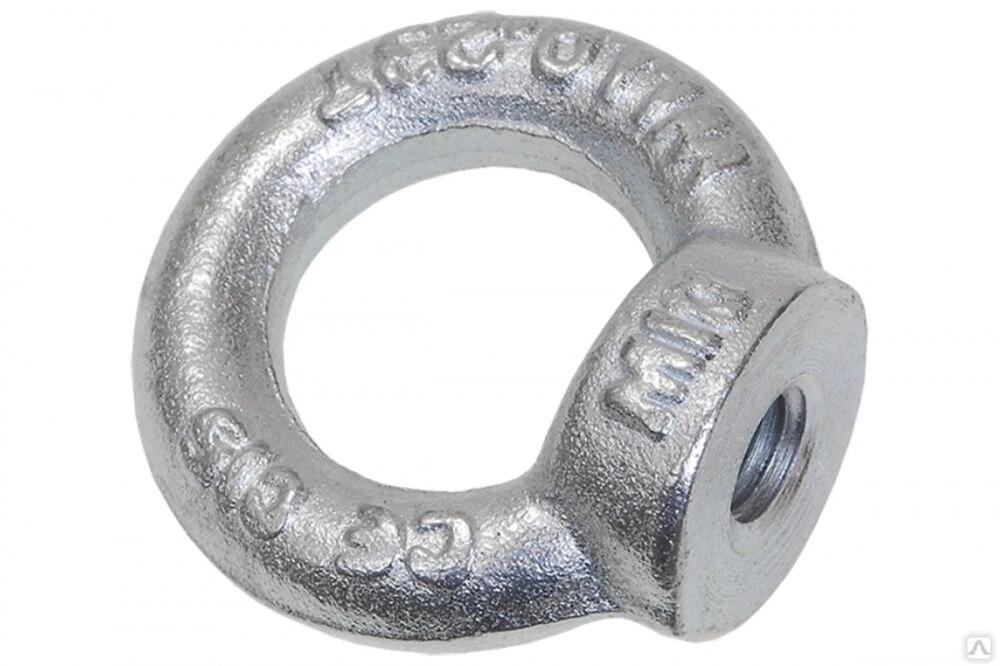

What are Turnbuckles?

A turnbuckle consists of a metal frame with two threaded eye bolts on either end, which can be rotated to shorten or lengthen the distance between them. This simple yet effective mechanism allows for precise tension adjustments. Turnbuckles are typically made from durable materials such as stainless steel, providing necessary strength and corrosion resistance. Depending on their application, they come in various sizes, with large turnbuckles catering to heavy-duty requirements.

Application in Construction

In construction, large turnbuckles are critical for supporting structural integrity. Tower cranes, scaffolding, and tension cables all leverage the adjustable nature of turnbuckles to maintain stability. For instance, when erecting high-rise buildings, contractors use turnbuckles to tension guy wires that stabilize cranes reaching staggering heights. Adjusting the tension is crucial for ensuring that these cranes can operate safely under various loads. Without high-quality turnbuckles, the risk of structural failure could significantly increase, leading to dangerous and potentially fatal outcomes.

Rigging and Maritime Use

famous large turnbuckles

The rigging industry relies heavily on large turnbuckles for securing loads and adjusting tension in various applications. In the maritime sector, they are used to control the tension in sail rigging, ensuring that the sails can be adjusted for optimal performance. Additionally, large turnbuckles are integrated into the mooring systems of ships and offshore platforms, ensuring that hulls are secure during adverse weather conditions. Their ability to endure harsh marine environments makes them indispensable tools for protecting property and enhancing safety.

Safety and Standards

The manufacturing and use of large turnbuckles come with a stringent set of standards to ensure safety and reliability. Organizations such as the American Society of Mechanical Engineers (ASME) provide guidelines for the design and testing of turnbuckles. These standards help prevent failures that could arise from improper tensioning or the use of subpar materials. Industries utilizing turnbuckles must adhere to these regulations to safeguard workers and equipment.

Innovations and Future Directions

As technology advances, the design and function of turnbuckles continue to evolve. Innovations such as automatic tensioning systems and smart sensors are being integrated into modern turnbuckle designs, allowing for real-time monitoring of tension levels. These advancements enhance safety and reliability, particularly in applications that involve dynamic forces and rapidly changing conditions. The future of turnbuckles looks promising as they adapt to new materials and technologies, reinforcing their importance in heavy-duty applications.

Conclusion

In summary, large turnbuckles are invaluable tools that play a vital role in various heavy-duty sectors. From construction to maritime operations, their ability to provide precise tension adjustments is crucial for safety and functionality. As industries continue to evolve, the significance and sophistication of turnbuckles will undoubtedly grow, solidifying their status as a cornerstone of mechanical engineering and ensuring safer workplaces and enhanced operational efficiency across the board.