News

Aug . 06, 2024 06:11 Back to list

Exploring ODM Rigging Supply Solutions for Effective and Reliable Product Development and Implementation

Understanding ODM Rigging Supply Products A Comprehensive Overview

In the realms of construction, maritime operations, and industrial applications, the importance of reliable and high-quality rigging supplies cannot be overstated. Original Design Manufacturing (ODM) rigging supply products are particularly noteworthy for their tailor-made solutions that cater to the specific needs of various industries. This article delves into what ODM rigging supply products are, their advantages, and their role in contemporary operations.

What are ODM Rigging Supply Products?

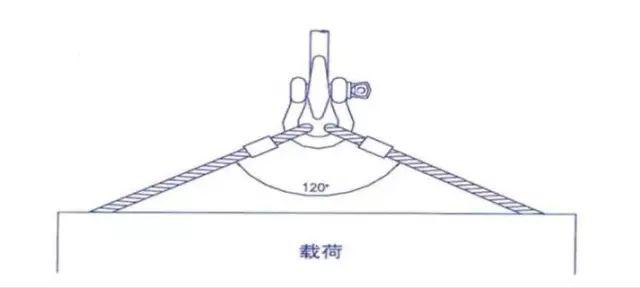

Original Design Manufacturing (ODM) refers to the process where a company designs and manufactures a product that is then sold under another company's brand. In the case of rigging supplies, ODM products are designed to meet unique specifications and requirements that might not be available in standard offerings. These products range from rigging hardware such as shackles, connectors, and pulleys to more complex systems that integrate various components for specialized applications.

Advantages of ODM Rigging Supplies

1. Customization and Flexibility One of the primary benefits of ODM rigging supplies is the ability to customize products according to the specific needs of a project. Each industry has its unique challenges and requirements, and ODM manufacturers can develop solutions that address these effectively. Whether it’s a particular load capacity, material specification, or environmental resistance, custom designs can significantly enhance performance and safety.

2. Quality Assurance ODM manufacturers typically maintain stringent quality control measures throughout the production process. By collaborating with experienced engineers and production teams, they ensure that products meet both regulatory standards and customer expectations. This commitment to quality is vital in virtually all applications where rigging supplies are employed, especially in high-risk environments.

odm rigging supply product

3. Cost Efficiency While the initial investment in ODM products may be higher due to custom designs, they often lead to cost savings in the long run. Custom rigging solutions can reduce the likelihood of equipment failures, minimize downtime, and lower maintenance costs. Additionally, tailored solutions can often optimize the use of resources, ensuring operations run more smoothly and efficiently.

4. Enhanced Safety Safety is paramount in any operation involving rigging. ODM products are designed with safety regulations and best practices in mind. Custom solutions can integrate additional safety features that standard products may lack, thereby reducing the risk of accidents. For example, unique safety locking mechanisms or fail-safes can be incorporated to protect against catastrophic failures.

5. Technological Integration The contemporary landscape of rigging supplies is increasingly influenced by technology. ODM manufacturers often embrace innovation, integrating modern technologies such as IoT sensors for real-time monitoring or advanced materials that offer better durability and performance. These advancements can revolutionize how rigging supplies are used and maintained.

The Role of ODM Rigging Supplies in Modern Industries

As industries grow and evolve, the demand for effective rigging solutions within construction, shipping, and entertainment sectors continues to rise. ODM rigging supply products play a vital role in this landscape. Whether it’s lifting heavy materials on a construction site, securing cargo on a vessel, or rigging equipment in a theater production, the tailored nature of ODM products ensures that each task can be performed safely and efficiently.

In conclusion, ODM rigging supply products represent a significant advancement in the world of rigging equipment. Their customizability, quality assurance, cost efficiency, safety features, and technological integration make them indispensable in various industries. As the market continues to demand more specialized solutions, ODM manufacturers will likely lead the charge in innovation, further solidifying their importance in the rigging supply domain.