News

Jul . 31, 2024 23:51 Back to list

Effective Eye Rigging Solutions for Safe and Efficient Lifting Operations in Various Industries

Understanding the Importance of Lifting Eyes in Rigging Products

In the world of rigging and lifting, safety and reliability are paramount. A crucial component in achieving these aspects is the use of lifting eyes, a fundamental product that plays an integral role in securing loads for transportation and lifting operations. This article explores the various types of lifting eyes, their applications, and the importance of selecting the right lifting products for different rigging needs.

What are Lifting Eyes?

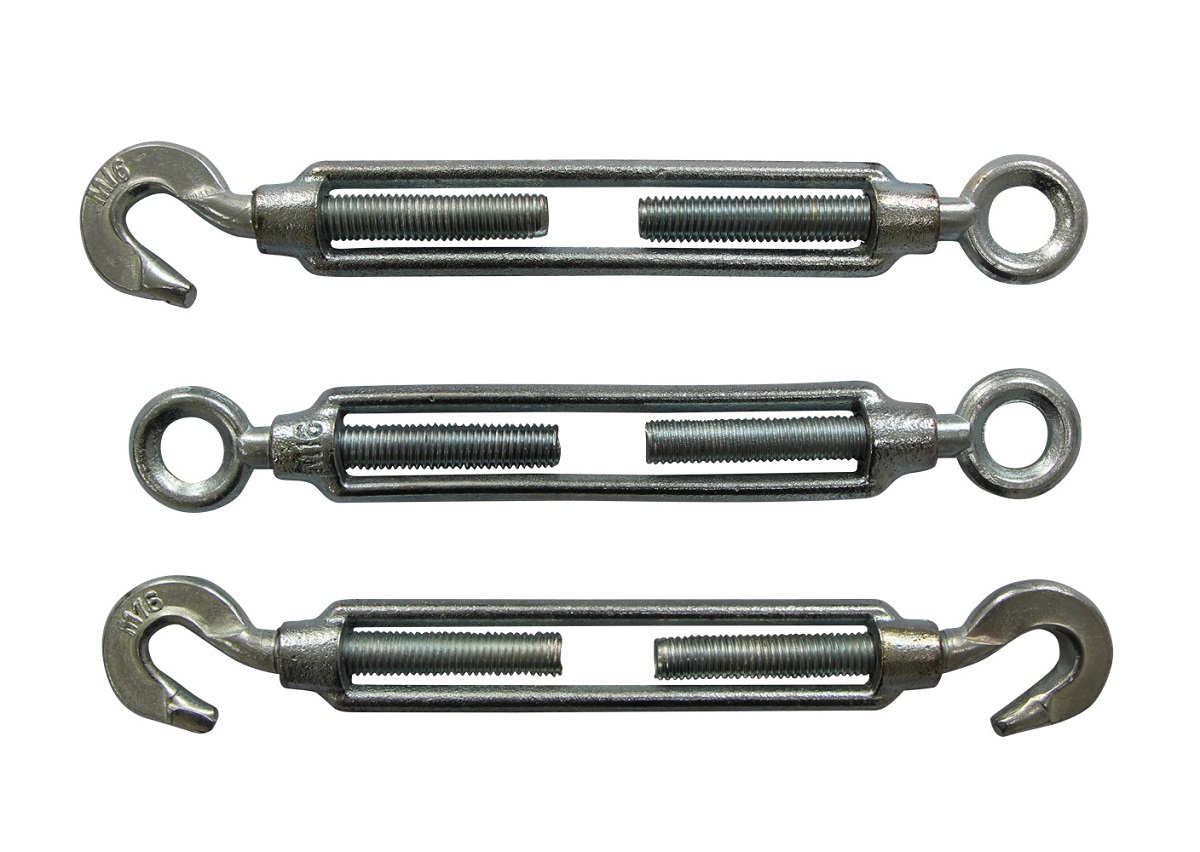

Lifting eyes, also known as lifting points or eyes, are metal hardware components designed to attach lifting equipment, such as slings and hooks, to a load. They are typically manufactured from high-strength materials like steel or alloy and are engineered to withstand significant loads. Lifting eyes come in various designs, including fixed, swivel, and folding types, each tailored to specific lifting tasks.

Types of Lifting Eyes

1. Fixed Lifting Eyes These are rigidly mounted and do not allow for movement once installed. They are generally used for straightforward lifting tasks where the load remains stable during transport.

2. Swivel Lifting Eyes These allow the lifting point to rotate, providing flexibility in different lifting angles. This is particularly useful when maneuvering loads that need to be repositioned or turned while being lifted.

3. Folding Lifting Eyes As the name suggests, these can be folded down when not in use, providing convenience and reducing snagging hazards. They are ideal for applications where the lifting point is not always needed.

lifting eyes rigging product

4. Custom Lifting Eyes For more complex lifting needs, custom lifting eyes can be manufactured to meet specific requirements, including unique shapes, sizes, and load capacities.

Applications of Lifting Eyes

Lifting eyes are utilized across various industries, including construction, manufacturing, shipping, and entertainment. In construction, they are essential for lifting heavy machinery, structures, and materials. In manufacturing, lifting eyes help in the assembly and movement of large components. The shipping industry often employs lifting eyes for securing cargo containers, while in entertainment, they are used for rigging lights and other equipment for stage productions.

Safety Considerations

With lifting eyes being critical to load safety, it is vital to choose high-quality products and adhere to load capacities. Each lifting eye comes with a specified working load limit (WLL), which indicates the maximum load that can be safely lifted. Exceeding these limits can lead to catastrophic failures, endangering personnel and property.

Before using lifting eyes, operators should inspect them for any signs of wear, deformation, or damage. Regular maintenance and replacement of worn components are essential for ensuring ongoing safety. Additionally, training for operators in load handling and rigging procedures is crucial for preventing accidents.

Conclusion

Lifting eyes are a vital component of rigging products that facilitate safe and efficient lifting operations across various industries. Understanding the types of lifting eyes, their applications, and the importance of proper safety protocols can enhance load handling practices. Investing in quality lifting products and adhering to safety standards not only protects workers but also ensures the successful completion of lifting tasks. As the industry continues to evolve, the development of innovative lifting solutions will further improve safety and efficiency in rigging operations.