News

Aug . 13, 2024 20:06 Back to list

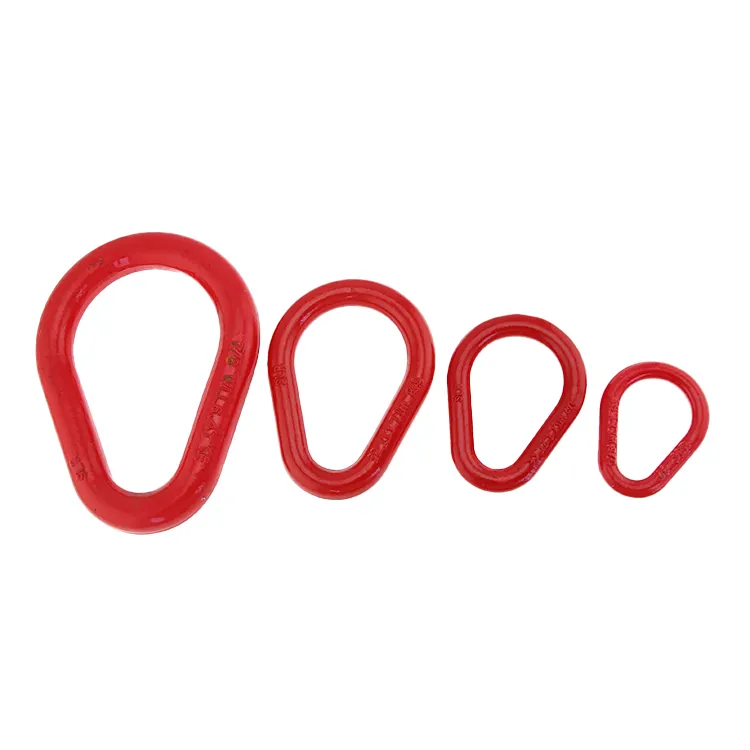

Durable and Versatile Rigging Thimbles for Reliable Heavy-Duty Applications and Secure Connections

Understanding the Importance of Rigging Thimbles in the Marine Industry

Rigging thimbles are small yet crucial components in the world of marine rigging and sailing. Often overlooked, these devices play a significant role in ensuring the safety and functionality of various rigging systems. This article delves into the importance, functions, and various applications of rigging thimbles, particularly in the marine industry.

Understanding the Importance of Rigging Thimbles in the Marine Industry

One of the main advantages of using thimbles is their ability to distribute load evenly. When a rope is looped over a thimble, the stress is not concentrated in one spot, which minimizes wear and extends the life of the rope. Additionally, thimbles help maintain the shape of the loop, which is critical in applications where the loop needs to pass through a block or other hardware without jamming or binding. This characteristic is particularly crucial in sailing, where the reliability of rigging directly impacts performance and safety.

rigging thimble product

In the marine industry, rigging thimbles are commonly used in various applications, including halyards, sheets, and anchor lines. High-quality thimbles are often made from robust materials such as stainless steel, aluminum, or galvanized steel to withstand the harsh marine environment. It is important to select the right material for specific conditions, as corrosion resistance, weight, and strength are significant considerations in marine applications.

Proper installation of rigging thimbles is also essential for optimal performance. When creating a loop with a thimble, it is recommended to use a suitable knot that will hold securely without slipping. The bowline knot is a popular choice due to its reliability, but it is crucial to ensure that the knot is tied correctly to prevent any potential failure. Regular inspections and maintenance of the rigging system, including the thimbles, ropes, and associated hardware, are also necessary to avoid accidents.

Moreover, thimbles come in various sizes and shapes, allowing users to choose the appropriate fitting for their specific needs. For instance, a larger thimble may be necessary for heavier applications, while smaller thimbles might be sufficient for lighter tasks. Understanding the specifications and matching them to the requirements of the job at hand is key in rigging applications.

In conclusion, rigging thimbles are an integral part of marine rigging that should not be overlooked. Their ability to reinforce ropes and distribute load effectively enhances the safety and performance of a variety of maritime activities. As boating and sailing remain popular pastimes and professions, understanding and using the right rigging components, including thimbles, is essential for ensuring that operations are carried out safely and efficiently. Investing in high-quality thimbles and adhering to best practices in installation and maintenance will not only extend the lifespan of rigging systems but also protect those who rely on them in the pursuit of adventure on the open water.