News

Jul . 25, 2024 22:03 Back to list

Custom Manufacturing of Stainless Steel Wire Rope Clips for Diverse Industrial Applications

Custom SS Wire Rope Clip Factory Quality and Precision in Every Detail

In today's fast-paced industrial environment, the need for reliable and durable hardware solutions is more vital than ever. Among these solutions, wire rope clips play an indispensable role in numerous applications, from construction to marine activities. These clips are designed to secure wire ropes, ensuring safety and stability in heavy-load conditions. A custom stainless steel (SS) wire rope clip factory specializes in manufacturing these critical components, providing tailored solutions to meet diverse customer needs.

Understanding Wire Rope Clips

Wire rope clips are small but essential components used to create a secure loop at the end of a wire rope or to join two ropes together. They are typically composed of a U-bolt, a saddle, and two nuts. The U-bolt grips the wire rope, while the saddle ensures that the rope is held tightly in place. Stainless steel is a preferred material due to its excellent resistance to corrosion, making it ideal for outdoor applications and environments prone to moisture.

The Importance of Customization

Every industry has unique requirements and specifications for wire rope clips. A custom SS wire rope clip factory understands this need for personalization. They offer a range of customization options including material grade, size, and design. This allows businesses to obtain clips that perfectly fit their application, enhancing performance and safety.

For instance, construction sites may require larger clips that can handle hefty loads, while marine applications could benefit from smaller, lightweight clips designed to withstand saltwater exposure. Moreover, some businesses may require clips that comply with specific industry standards or regulations. Custom manufacturing enables these industries to acquire products that meet their precise specifications.

Quality Assurance and Manufacturing Process

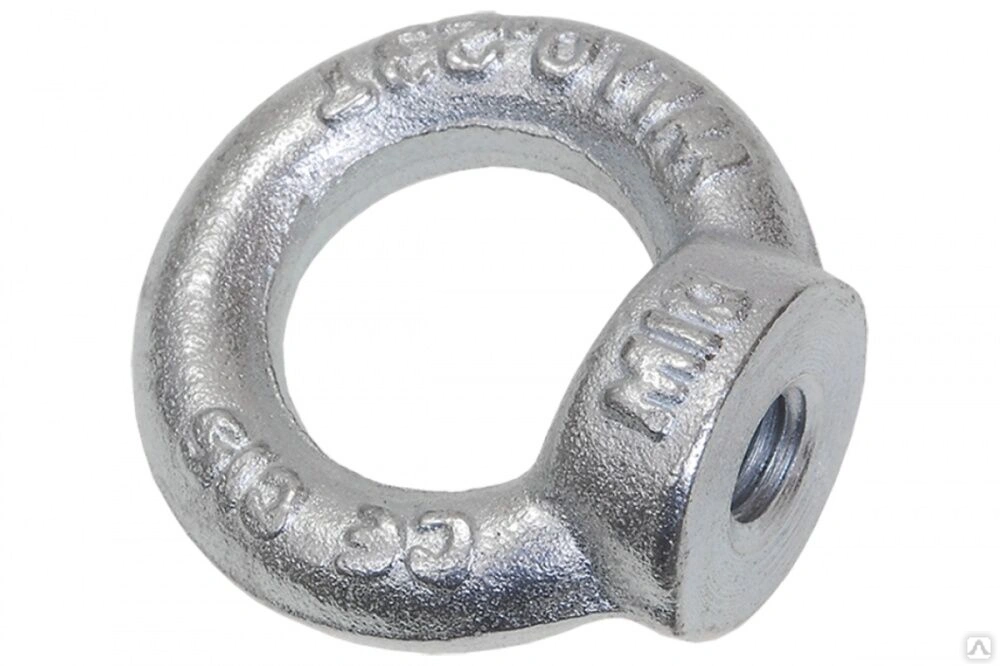

custom ss wire rope clip factory

A reputable custom SS wire rope clip factory emphasizes quality assurance throughout its manufacturing process. From the selection of high-grade materials to advanced production techniques, every step is meticulously monitored to ensure that the final product meets established standards. Factories often implement stringent quality control measures, including testing the tensile strength of clips and inspecting for surface defects.

Modern manufacturing technologies, such as CNC machining and precision forging, play an essential role in producing high-quality wire rope clips. These techniques allow for increased precision and consistency, reducing the risk of manufacturing defects that could lead to failure during use.

Sustainability and Ethical Practices

In an era where environmental responsibility is becoming increasingly significant, custom SS wire rope clip factories are also focusing on sustainable practices. This includes using recycled materials whenever feasible, minimizing waste during production, and employing energy-efficient processes. By adopting such measures, factories not only contribute to environmental preservation but also appeal to environmentally-conscious consumers and businesses.

Conclusion Your Go-To Partner for Wire Rope Solutions

When it comes to heavy-duty applications, the reliability of wire rope clips is paramount. A custom SS wire rope clip factory stands out as a trusted partner for businesses seeking high-quality, tailored solutions. With the capability to customize products, maintain rigorous quality standards, and embrace sustainability, these factories cater to a wide variety of industries while prioritizing safety and reliability.

Investing in custom wire rope clips is a strategic decision that can lead to enhanced operational efficiency and safety. No matter the industry, finding a factory that understands your specific needs will ensure that you have the right components to support your success. For businesses looking to source their wire rope clips, collaborating with a dedicated and experienced factory is an investment that pays off in the long run, supporting safety and reliability in every project.