News

Aug . 15, 2024 09:04 Back to list

Custom Eye Bolt Manufacturing and Supply Solutions for Diverse Industry Applications and Needs

Understanding Custom Eye Bolt Supply Factories

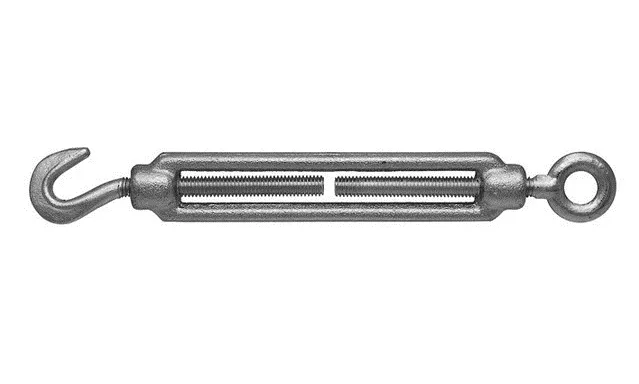

In the fast-paced world of manufacturing and supply chains, the importance of specialized components like custom eye bolts cannot be overstated. Eye bolts are crucial hardware items that provide a secure point for attaching cables, ropes, and other fixtures. The demand for custom eye bolts has surged across various industries, prompting the rise of dedicated supply factories that specialize in these components. This article delves into the significance of custom eye bolt supply factories, their manufacturing processes, and their impact on diverse sectors.

The Role of Custom Eye Bolts

Custom eye bolts are tailored to meet specific requirements, such as unique dimensions, materials, and load capacities. These components serve critical functions in construction, maritime, aerospace, and automotive applications, among others. For instance, in the construction industry, eye bolts are used to secure heavy machinery and structural elements, ensuring safety and stability. In marine applications, they provide reliable anchoring points for mooring boats and other vessels. The versatility of eye bolts makes them essential across multiple fields, necessitating the customization to fit precise needs.

Manufacturing Process of Custom Eye Bolts

Custom eye bolt supply factories employ advanced manufacturing techniques to produce high-quality components. The process typically begins with an in-depth consultation with clients to understand their requirements. Factors such as the intended application, load-bearing capacity, environmental conditions, and aesthetic preferences are thoroughly discussed. This initial phase ensures that the final product not only meets but exceeds the client's expectations.

Once the specifications are established, the design phase commences. Engineers utilize computer-aided design (CAD) software to create detailed schematics of the eye bolts. These designs are pivotal in visualizing how the final product will look and function. After approval, the production phase begins. Factories utilize various materials such as stainless steel, carbon steel, or alloy steel, chosen based on the application and environmental exposure.

custom eye bolt supply factories

The manufacturing process involves techniques like forging, machining, and heat treatment to enhance the strength and durability of the eye bolts. Quality control is integrated at every stage of production, ensuring that each batch of eye bolts complies with industry standards and regulations. This rigorous quality assurance is crucial, as any defect in these critical components can lead to failure and potential hazards.

Advantages of Custom Supply Factories

One of the main advantages of working with custom eye bolt supply factories is the ability to tailor solutions specifically to project needs. Off-the-shelf products may not always suffice, especially for specialized applications. Custom manufacturers can provide products that precisely meet the specifications, leading to improved performance and safety.

Moreover, these factories can respond quickly to changing market demands and technological advancements. They often maintain strong relationships with their clients, enabling them to provide timely support, modifications, and even design innovations. The flexibility and responsiveness of custom supply factories make them invaluable partners in the manufacturing ecosystem.

Conclusion

Custom eye bolt supply factories are at the forefront of meeting the intricate demands of modern industries. With their ability to design and manufacture specialized components, they ensure that businesses have access to high-quality products that enhance safety and efficiency. As industries evolve and the need for customized solutions grows, these factories will continue to play a pivotal role in shaping the future of hardware supply. Whether for construction, marine, or aerospace applications, the contribution of custom eye bolts remains integral to the success and safety of innumerable projects worldwide.