News

Jan . 16, 2025 05:46 Back to list

china shackles & parts archives

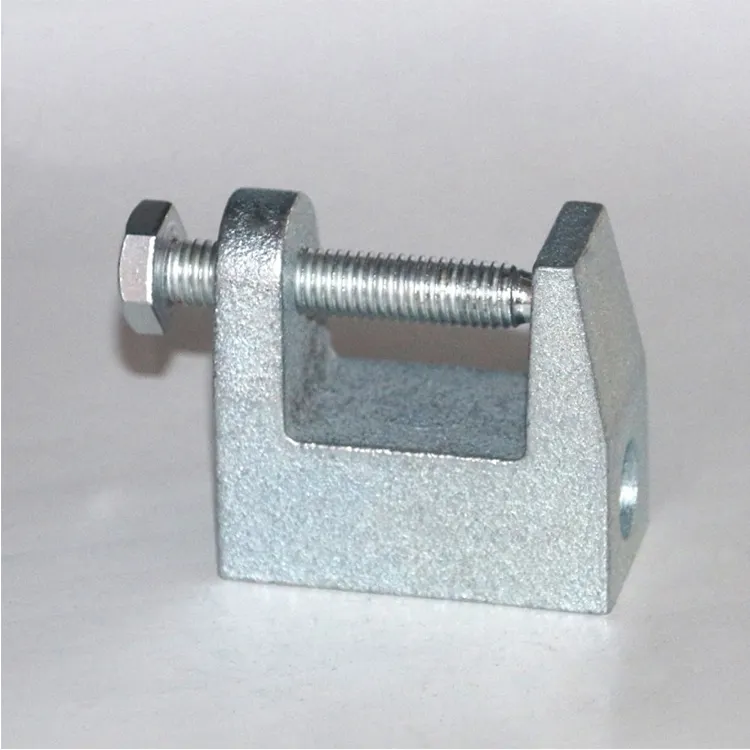

The world of industrial components is vast and intricate, with various products serving different functions, each integral to the overall machinery or structure. Among these, shackles and their parts play a crucial role in numerous applications across different industries, from shipping to construction. Understanding these products' various facets, especially those sourced from China, can significantly aid businesses looking to invest in reliable components.

Industry experience also underscores the importance of inspecting the finish and markings on these products. Reliable marks indicate a track record of quality assurance and traceability—which are essential for safety-critical applications. Chinese manufacturers offer a wide range of finishes, including hot-dip galvanization and powder coating, which enhance the product's aesthetic appeal and resistance to environmental factors. Beyond the technical specifications, logistical considerations also play a part in decision-making. With China's robust export infrastructure, supply chain efficiencies can be realized, helping reduce shipping times and costs. This logistical advantage, coupled with competitive pricing, often makes Chinese shackles an attractive option for businesses worldwide. However, ensuring trustworthiness and building a relationship with Chinese suppliers involves due diligence. Vetting suppliers via factory audits, seeking certifications, and leveraging partnerships with well-regarded firms can bolster confidence in the supply chain. Furthermore, testimonials and case studies from other businesses utilizing these products provide insights into long-term reliability and performance. To leverage these advantages effectively, businesses must stay informed about market trends and technological advancements. Chinese manufacturers continuously innovate, offering new designs and enhanced materials, which savvy businesses can capitalize on to maintain a competitive edge. In conclusion, while the Chinese market for shackles and their parts is abundant with options, achieving a balance between cost, quality, and logistical feasibility is crucial. By focusing on expertise, authoritative sources, and building trustworthy supplier relationships, businesses can capitalize on China's manufacturing prowess to meet their industrial hardware needs efficiently and effectively.

Industry experience also underscores the importance of inspecting the finish and markings on these products. Reliable marks indicate a track record of quality assurance and traceability—which are essential for safety-critical applications. Chinese manufacturers offer a wide range of finishes, including hot-dip galvanization and powder coating, which enhance the product's aesthetic appeal and resistance to environmental factors. Beyond the technical specifications, logistical considerations also play a part in decision-making. With China's robust export infrastructure, supply chain efficiencies can be realized, helping reduce shipping times and costs. This logistical advantage, coupled with competitive pricing, often makes Chinese shackles an attractive option for businesses worldwide. However, ensuring trustworthiness and building a relationship with Chinese suppliers involves due diligence. Vetting suppliers via factory audits, seeking certifications, and leveraging partnerships with well-regarded firms can bolster confidence in the supply chain. Furthermore, testimonials and case studies from other businesses utilizing these products provide insights into long-term reliability and performance. To leverage these advantages effectively, businesses must stay informed about market trends and technological advancements. Chinese manufacturers continuously innovate, offering new designs and enhanced materials, which savvy businesses can capitalize on to maintain a competitive edge. In conclusion, while the Chinese market for shackles and their parts is abundant with options, achieving a balance between cost, quality, and logistical feasibility is crucial. By focusing on expertise, authoritative sources, and building trustworthy supplier relationships, businesses can capitalize on China's manufacturing prowess to meet their industrial hardware needs efficiently and effectively.

Share

Next: