News

Jun . 13, 2024 04:32 Back to list

3/4 inch manufacturer's shackles available

Understanding the Significance of Manufacturer 3/4 Shackles A Comprehensive Guide

In the world of rigging and heavy lifting, the role of manufacturer 3/4 shackles cannot be overstated. These sturdy connectors play a pivotal part in ensuring safety and efficiency in various industries, from construction to maritime operations. This article aims to delve into the intricacies of these essential tools, exploring their design, usage, and the importance of selecting the right manufacturer.

A 3/4 shackle, as the name suggests, refers to a type of lifting shackle with a diameter of three-quarters of an inch. It is a 'D' shaped device, typically made from high-strength materials like carbon steel or stainless steel, designed to connect two points for secure lifting or towing. The size is a crucial factor, as it determines the weight capacity and suitability for specific tasks. A 3/4 shackle, for instance, can typically handle loads ranging from moderate to heavy, making them versatile in many applications.

The design of manufacturer 3/4 shackles is centered around strength and durability. The 'D' shape provides a wide load-bearing area, minimizing stress concentration and enhancing load distribution. The threaded pin, often secured with a nut or a cotter pin, ensures a tight and secure connection. However, it's not just about the physical attributes; the quality of the material and the manufacturing process significantly impact the shackle's performance.

When it comes to choosing a manufacturer, it's vital to prioritize safety and reliability. Look for manufacturers that adhere to international standards like ASME B30 Look for manufacturers that adhere to international standards like ASME B30 Look for manufacturers that adhere to international standards like ASME B30 Look for manufacturers that adhere to international standards like ASME B30

Look for manufacturers that adhere to international standards like ASME B30 Look for manufacturers that adhere to international standards like ASME B30 manufacturer 3/4 shackles.20, EN 1677, or OSHA regulations. These standards ensure that the shackles undergo rigorous testing and inspections, guaranteeing their integrity under load. Manufacturers who invest in advanced forging techniques and use high-grade materials can provide shackles with superior tensile strength and resistance to corrosion.

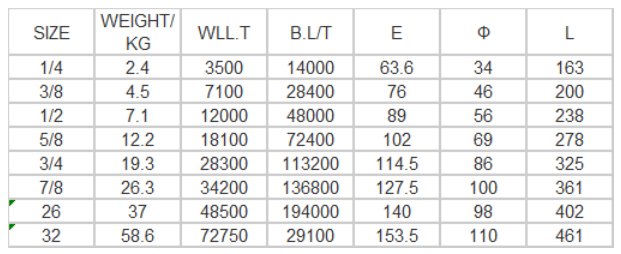

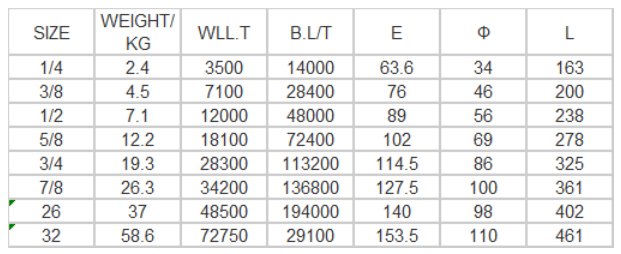

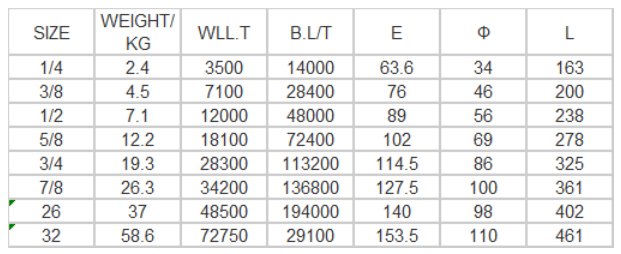

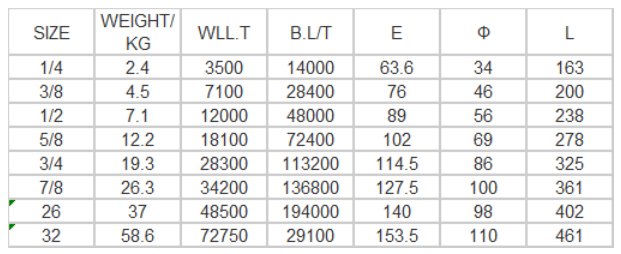

Furthermore, a reputable manufacturer will provide detailed information on the shackle's Working Load Limit (WLL) and Ultimate Tensile Strength (UTS). Misunderstanding or ignoring these specifications can lead to catastrophic failures. Always select a shackle with a WLL that exceeds the expected load, leaving a safety margin to account for unpredictable conditions.

Beyond the product itself, a reliable manufacturer should also offer excellent customer service, including technical support and guidance on proper usage and maintenance. Regular inspection and timely replacement of worn or damaged shackles are essential to maintain their effectiveness.

In conclusion, manufacturer 3/4 shackles are more than just simple connectors; they are lifelines in many industrial operations. Understanding their function, selecting the right manufacturer, and adhering to safety guidelines are crucial steps to ensure safety and optimize performance. Remember, a well-made 3/4 shackle is an investment in both productivity and peace of mind.

manufacturer 3/4 shackles.20, EN 1677, or OSHA regulations. These standards ensure that the shackles undergo rigorous testing and inspections, guaranteeing their integrity under load. Manufacturers who invest in advanced forging techniques and use high-grade materials can provide shackles with superior tensile strength and resistance to corrosion.

Furthermore, a reputable manufacturer will provide detailed information on the shackle's Working Load Limit (WLL) and Ultimate Tensile Strength (UTS). Misunderstanding or ignoring these specifications can lead to catastrophic failures. Always select a shackle with a WLL that exceeds the expected load, leaving a safety margin to account for unpredictable conditions.

Beyond the product itself, a reliable manufacturer should also offer excellent customer service, including technical support and guidance on proper usage and maintenance. Regular inspection and timely replacement of worn or damaged shackles are essential to maintain their effectiveness.

In conclusion, manufacturer 3/4 shackles are more than just simple connectors; they are lifelines in many industrial operations. Understanding their function, selecting the right manufacturer, and adhering to safety guidelines are crucial steps to ensure safety and optimize performance. Remember, a well-made 3/4 shackle is an investment in both productivity and peace of mind.

Look for manufacturers that adhere to international standards like ASME B30 Look for manufacturers that adhere to international standards like ASME B30

Look for manufacturers that adhere to international standards like ASME B30 Look for manufacturers that adhere to international standards like ASME B30 manufacturer 3/4 shackles.20, EN 1677, or OSHA regulations. These standards ensure that the shackles undergo rigorous testing and inspections, guaranteeing their integrity under load. Manufacturers who invest in advanced forging techniques and use high-grade materials can provide shackles with superior tensile strength and resistance to corrosion.

Furthermore, a reputable manufacturer will provide detailed information on the shackle's Working Load Limit (WLL) and Ultimate Tensile Strength (UTS). Misunderstanding or ignoring these specifications can lead to catastrophic failures. Always select a shackle with a WLL that exceeds the expected load, leaving a safety margin to account for unpredictable conditions.

Beyond the product itself, a reliable manufacturer should also offer excellent customer service, including technical support and guidance on proper usage and maintenance. Regular inspection and timely replacement of worn or damaged shackles are essential to maintain their effectiveness.

In conclusion, manufacturer 3/4 shackles are more than just simple connectors; they are lifelines in many industrial operations. Understanding their function, selecting the right manufacturer, and adhering to safety guidelines are crucial steps to ensure safety and optimize performance. Remember, a well-made 3/4 shackle is an investment in both productivity and peace of mind.

manufacturer 3/4 shackles.20, EN 1677, or OSHA regulations. These standards ensure that the shackles undergo rigorous testing and inspections, guaranteeing their integrity under load. Manufacturers who invest in advanced forging techniques and use high-grade materials can provide shackles with superior tensile strength and resistance to corrosion.

Furthermore, a reputable manufacturer will provide detailed information on the shackle's Working Load Limit (WLL) and Ultimate Tensile Strength (UTS). Misunderstanding or ignoring these specifications can lead to catastrophic failures. Always select a shackle with a WLL that exceeds the expected load, leaving a safety margin to account for unpredictable conditions.

Beyond the product itself, a reliable manufacturer should also offer excellent customer service, including technical support and guidance on proper usage and maintenance. Regular inspection and timely replacement of worn or damaged shackles are essential to maintain their effectiveness.

In conclusion, manufacturer 3/4 shackles are more than just simple connectors; they are lifelines in many industrial operations. Understanding their function, selecting the right manufacturer, and adhering to safety guidelines are crucial steps to ensure safety and optimize performance. Remember, a well-made 3/4 shackle is an investment in both productivity and peace of mind. Share