News

Nov . 16, 2024 12:37 Back to list

1 8 eye bolt factories

Understanding the Role and Significance of Eye Bolt Factories

In the world of manufacturing and engineering, eye bolts play a crucial role in various applications, particularly in lifting, rigging, and securing loads. Eye bolts are simple yet incredibly effective hardware devices designed for connecting chains, ropes, or cable to a fixed point. With the increasing demand for these components in industries such as construction, shipping, and automotive, the significance of eye bolt factories has grown tremendously. This article delves into the functions, types, and benefits of eye bolts while highlighting the indispensable role of factories that produce these essential items.

The Function of Eye Bolts

Eye bolts are designed with a loop or eye at one end, allowing for easy attachment to a rope, hook, or other connecting hardware. Their primary function is to provide a secure anchor point for lifting or pulling objects. In constructions sites, they are often used to lift heavy materials, ensuring that safety protocols are followed. Furthermore, eye bolts can be found in various applications, from securing loads in shipping containers to providing connection points in rigging systems for theatrical productions.

Types of Eye Bolts

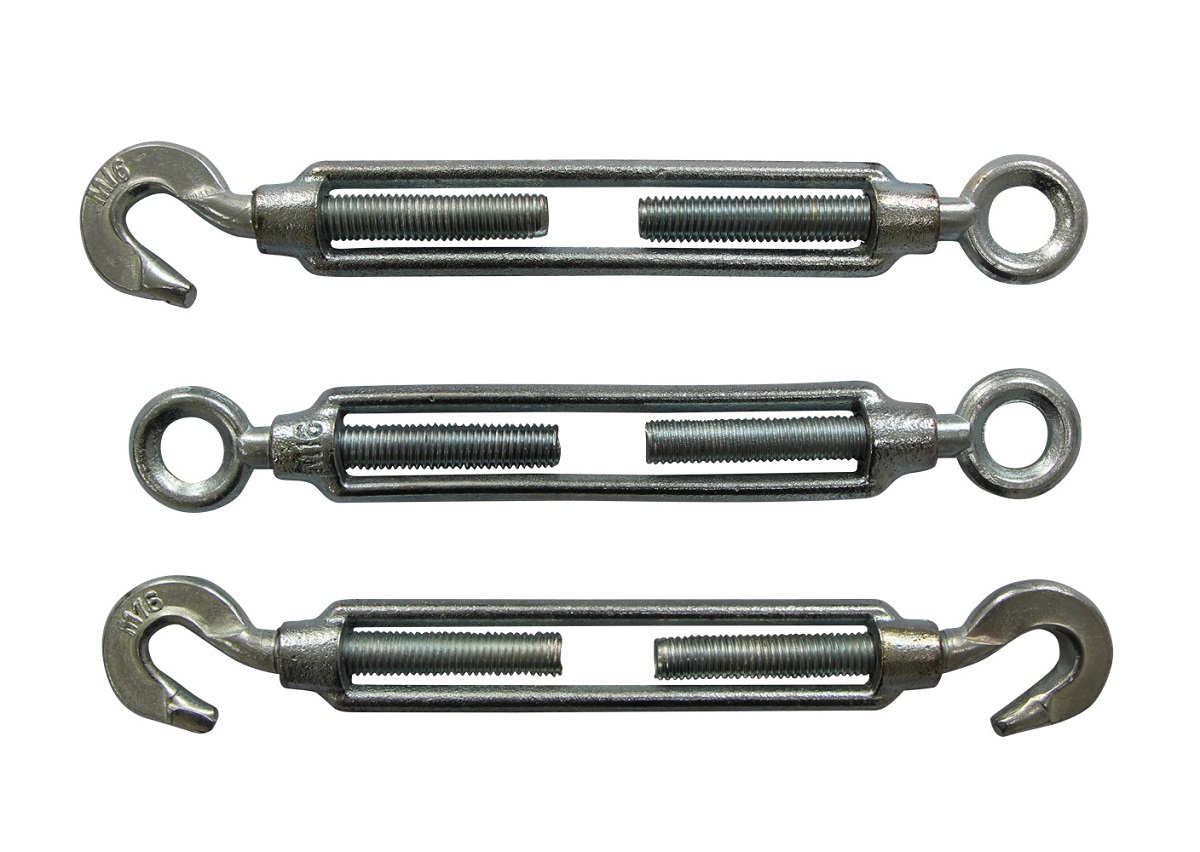

Eye bolts come in various types, each designed to meet specific requirements. The most common types include

1. Shoulder Eye Bolts These feature a shoulder that helps distribute the load and adds a significant safety factor, making them suitable for dynamic loads.

2. Regular Eye Bolts These are simple bolts with a loop that can handle static loads and are widely used in less demanding situations.

4. Through-Bolt Eye Bolts These require a hole through which the bolt passes, ensuring a tighter, more secure attachment.

Each type of eye bolt serves a unique purpose, and understanding the differences is essential for selecting the right one for specific applications.

1 8 eye bolt factories

Manufacturing Eye Bolts The Factory's Role

The manufacturing of eye bolts involves various processes, including material selection, forging, machining, and finishing. Factories dedicated to producing eye bolts typically employ advanced technology and skilled labor to ensure high-quality products. The process begins with the selection of material, usually steel or stainless steel, which provides the necessary strength and durability. Once the material is chosen, it undergoes forging to create the desired bolt shape.

Machining follows, where fine-tuning is performed to ensure precise dimensions and threads. Finally, finishing processes such as galvanizing or powder coating are applied to protect the eye bolts from corrosion and wear, increasing their lifespan. Factories prioritize quality control throughout this process, implementing rigorous testing methods to guarantee that each eye bolt can withstand the specified loads and conditions.

Benefits of Eye Bolt Manufacturing

Having dedicated eye bolt factories is vital for several reasons

- Consistency and Quality Factories specializing in eye bolts provide consistency in product quality. This reduces the risk of failure in critical lifting and rigging operations, ensuring the safety of users and loads.

- Customization Many manufacturers offer custom solutions, allowing industries to request specific sizes, materials, and features tailored to their unique requirements.

- Innovation With competition in the manufacturing sector, factories continuously seek innovative methods to improve the design and functionality of eye bolts. This leads to the development of new types that meet the evolving needs of various industries.

- Economic Impact Eye bolt factories contribute to the economy by providing jobs, stimulating local economies, and engaging in international trade.

Conclusion

In summary, eye bolt factories play an essential role in the manufacturing landscape by producing critical hardware that supports various industries. The significance of eye bolts, with their diverse types and applications, cannot be overstated. As demand continues to rise, the factories that produce these components will remain integral to ensuring safety, efficiency, and innovation in lifting and securing systems. Understanding the importance of these factories helps appreciate the intricacies of manufacturing and the role it plays in our daily lives, reinforcing the idea that even the simplest components can have a profound impact on safety and functionality.