News

ສ.ຫ. . 13, 2024 17:26 Back to list

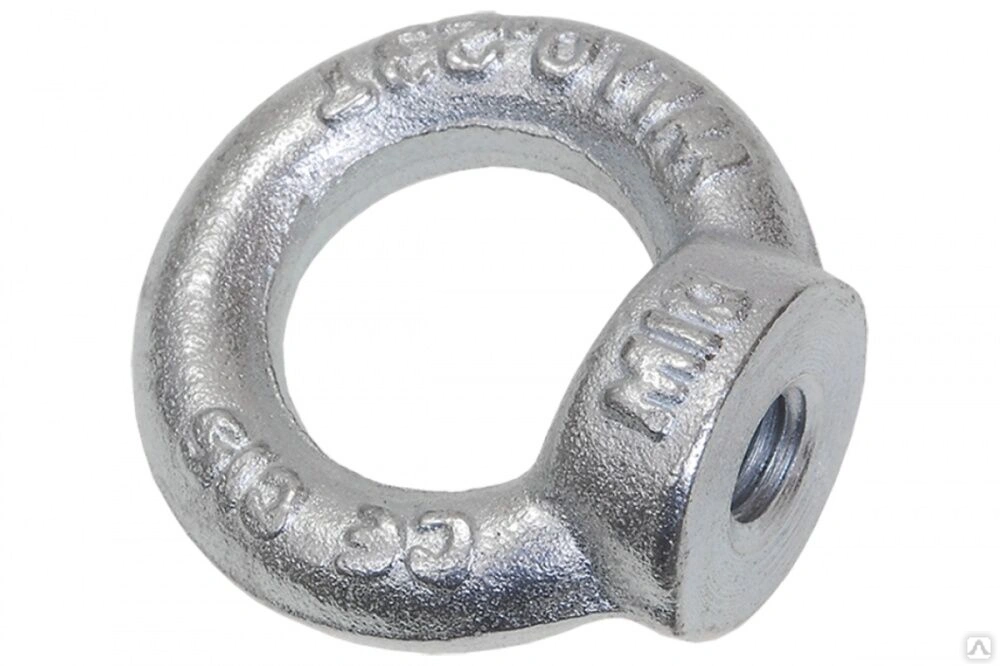

High-Quality Turnbuckles from Reliable Manufacturers for Various Industrial Applications and Projects

Understanding Turnbuckles Key Components and Their Importance in Construction

In the world of construction and industrial applications, turnbuckles play a critical role in providing tension to various structural elements. The term turnbuckle refers to a mechanical device that consists of a metal frame with two threaded ends, where each end is connected to a cable, rod, or other fasteners. This unique design allows for the adjustment of tension between these components, making it invaluable in numerous applications. In this article, we will explore the functionality, types, and significance of turnbuckles, with a particular focus on the 1/2 inch turnbuckle, often manufactured by specialized factories.

The Functionality of Turnbuckles

The primary purpose of a turnbuckle is to adjust the tension or length of cable or wire rope in various constructions. This adjustability is essential in applications such as suspension bridges, rigging systems, and theatrical setups, where tension control is crucial for stability and safety. Turnbuckles are especially prevalent in situations where a fixed length is required, but slight adjustments are necessary, either due to environmental factors or load changes.

When using a turnbuckle, tension is applied by rotating the central body of the device, which simultaneously increases or decreases the distance between the two threaded ends. This simple yet effective mechanism allows for precise control over the amount of tension applied to the connected elements.

Types of Turnbuckles

Turnbuckles come in various sizes and designs to cater to different requirements. The 1/2 inch turnbuckle is a common choice for both residential and commercial projects due to its balance of strength and versatility. The classification of turnbuckles generally depends on their end fittings, which can include

1/2 turnbuckle factory

2. Jaw End Turnbuckles Featuring a jaw attachment suitable for connecting to other rods or loops, these are often used in situations where a secure connection is paramount.

3. Closed Body Turnbuckles These types offer a more compact design, often utilized in applications with limited space.

4. Open Body Turnbuckles These provide a larger inspection area and are easy to handle for applications that require frequent adjustments.

Significance of Quality Manufacturing

The quality of turnbuckles, especially those manufactured in factories specializing in these devices, cannot be overstated. A well-made turnbuckle from a reliable factory will ensure longevity and safety. Look for turnbuckles made from high-grade materials like stainless steel or galvanized steel, which offer enhanced resistance against corrosion and wear. Furthermore, adherence to industry standards during production guarantees that the turnbuckles can withstand the required loads and tensions.

Conclusion

Turnbuckles, particularly 1/2 inch turnbuckles, are indispensable tools in various fields, extending their applications from construction to theater rigging. Understanding their functionality, types, and the importance of quality manufacturing can significantly impact safety and efficiency in your projects. As industries continue to evolve, the demand for reliable and adaptable hardware like turnbuckles will likely grow, making it essential for manufacturers to maintain high standards of production. Whether you are a builder, a rigger, or simply a DIY enthusiast, appreciating the role and significance of turnbuckles will enhance your project’s success and safety.