News

تشرینی یەکەم . 13, 2024 22:33 Back to list

supplier master links shackles wire ropes must be capable of supporting

The Importance of Supplier Master Links and Shackles in Wire Rope Applications

In the realm of industrial lifting and rigging, the choice of components is critical for ensuring safety, efficiency, and reliability. Among these components, supplier master links and shackles play a pivotal role, particularly when it comes to wire rope applications. The ability of these hardware items to support significant loads makes them essential in various industries, ranging from construction to shipping.

Understanding Supplier Master Links and Shackles

Supplier master links are the central connecting point in a lifting assembly. They are designed to distribute the load evenly among different lifting components, which helps prevent undue stress on individual parts. Shackles, on the other hand, are U-shaped devices with a pin that connect different parts of a rigging system. Together, these components form a crucial part of lifting operations.

Properly engineered master links and shackles are capable of supporting extremely heavy weights. The quality of the materials used, the manufacturing process, and the design specifications all contribute to their strength. Often crafted from high-strength alloy steel, master links and shackles are subjected to stringent testing standards to ensure their reliability under various conditions.

Compliance and Standards

In industries where safety is paramount, compliance with international standards is not just recommended – it's required. Products such as master links and shackles must meet specifications outlined by organizations like the American National Standards Institute (ANSI) and the Occupational Safety and Health Administration (OSHA). These regulatory bodies set guidelines that manufacturers must follow to ensure that these components can withstand the loads they will encounter in real-world applications.

When selecting supplier master links and shackles, it's crucial to verify that they have been tested for stress and met the required safety factor. A reputable supplier will provide documentation proving that their products have undergone rigorous testing and meet or exceed these standards.

supplier master links shackles wire ropes must be capable of supporting

Importance of Load Capacity

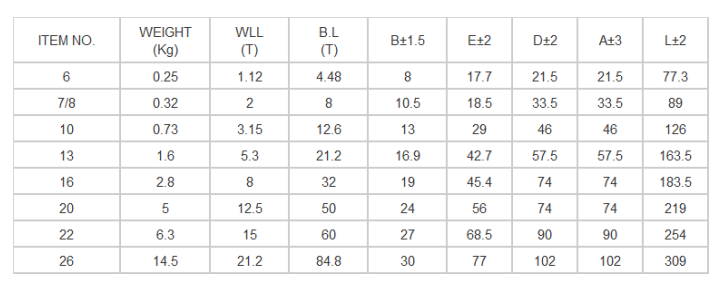

The load capacity of a master link or shackle is determined by various factors, including the design and the strength of the material used. It's also essential to consider the working load limit (WLL) of the wire rope being used in conjunction with these components. All parts in a rigging system should be compatible in terms of load capacity to ensure a balanced distribution of weight and minimal risk of failure.

Rigging equipment is often subject to dynamic loads, which can be significantly higher than static loads. For instance, when lifting a load that starts and stops or swings, the forces applied can exceed the weight of the load itself. Therefore, when selecting master links and shackles, it's crucial to choose those with an adequate safety factor to accommodate these potential increases in load.

Regular Inspection and Maintenance

Regular inspection and maintenance of master links and shackles are essential to their longevity and effectiveness. Over time, components can suffer from wear and fatigue due to repetitive use, harsh environmental conditions, or improper handling. Signs of damage, such as bending, cracking, or corrosion, can compromise their performance and safety.

Implementing a routine inspection schedule ensures that any issues can be identified and addressed before they lead to catastrophic failures. Additionally, proper storage and handling practices can extend the life of these components, ensuring they remain capable of supporting the loads for which they are designed.

Conclusion

In conclusion, supplier master links and shackles are indispensable components in the domain of wire rope applications. Their ability to safely support heavy loads while complying with strict industry standards makes them crucial in enhancing safety and reliability in lifting operations. By choosing high-quality components and adhering to regular inspection and maintenance routines, industries can ensure that their rigging systems remain effective and safe for years to come. Proper knowledge and practice in selecting and utilizing these components can lead to significant improvements in operational efficiency and risk management in lifting operations.