- +8613831024085

- infohengou@gmail.com

News

11월 . 15, 2024 16:42 Back to list

wide mouth beam clamp factories

Understanding Wide Mouth Beam Clamps A Guide to Factories and Manufacturing

In the realm of construction and industrial applications, the versatility and safety provided by beam clamps are indispensable. Among these, the wide mouth beam clamp stands out for its unique design that accommodates a variety of beam sizes, making it an essential tool for rigging, lifting, and securing loads. This article delves into the world of wide mouth beam clamp factories, focusing on their manufacturing processes, quality standards, and the significance they hold in various industries.

What is a Wide Mouth Beam Clamp?

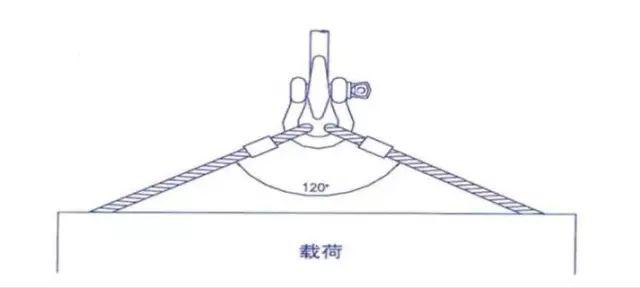

A beam clamp is a mechanical device used to securely fasten to a beam and facilitate the lifting of loads. The wide mouth variant features an adjustable opening that allows it to grip larger beams effectively. These clamps are widely utilized in construction sites, manufacturing plants, and maintenance operations, where safety and stability are paramount.

Importance of Factories in Beam Clamp Production

The manufacturing of wide mouth beam clamps is a specialized process that demands precision and adherence to safety standards. Factories that produce these clamps typically employ advanced technologies and skilled labor to ensure the highest quality. Key aspects of these factories include

1. Material Selection High-quality raw materials, such as durable steel or alloy, are essential for producing beam clamps that can withstand considerable stress and weight. Factories prioritize sourcing materials that meet industry standards for strength and corrosion resistance.

2. Precision Engineering The design of wide mouth beam clamps must be meticulously engineered to ensure they fit securely around various beam sizes. Advanced CNC (Computer Numerical Control) machines are often utilized in the manufacturing process to achieve the necessary precision and uniformity in component parts.

3. Quality Control Reliable factories implement stringent quality control measures at every stage of production. This may involve rigorous testing of the clamps under load conditions, inspections of material integrity, and evaluations of finish quality to guarantee that each product meets safety regulations.

4. Customization Different applications may require unique specifications for beam clamps. Many factories offer customization options, allowing customers to specify dimensions, load capacities, and finishes according to their needs. This flexibility is crucial for industries that require tailored solutions for specific challenges.

wide mouth beam clamp factories

Challenges Faced by Wide Mouth Beam Clamp Factories

While the demand for wide mouth beam clamps is strong across various industries, factories must navigate several challenges in their operations

1. Global Competition With an increase in global manufacturing capabilities, factories must stay competitive by optimizing their production processes and reducing costs without compromising quality. This often involves investing in new technologies and advancements.

2. Regulatory Compliance Factories must ensure they comply with local and international regulations regarding manufacturing practices, safety standards, and environmental impact. This can require significant resources for both initial compliance and ongoing evaluations.

3. Supply Chain Disruptions Just like other manufacturing sectors, beam clamp factories can face disruptions in their supply chains, impacting the timely delivery of raw materials and production schedules. Developing resilient supply chains has become essential for maintaining operational efficiency.

The Future of Wide Mouth Beam Clamps

The increasing focus on safety in construction and industrial practices suggests that the demand for high-quality beam clamps will continue to grow. Innovations in material science and manufacturing technologies promise to enhance the capabilities of wide mouth beam clamps, making them even more reliable and versatile.

As the industries evolve, the role of factories will also change, emphasizing the importance of sustainability, efficiency, and adaptability to new methods and materials. Factories that embrace these changes will not only bolster their market positions but also contribute significantly to the advancement of safety standards in the industry.

Conclusion

Wide mouth beam clamps are essential components in various applications, ensuring safe and efficient lifting and securing of loads. Factories producing these clamps play a crucial role in their design, manufacturing, and quality control. While challenges exist, the future remains bright for these facilities as they adapt to new technologies and meet the ever-growing demands of industries worldwide. By prioritizing quality and innovation, wide mouth beam clamp factories will continue to support the backbone of construction and manufacturing sectors around the globe.