News

11월 . 21, 2024 23:41 Back to list

supplier types of rigging equipment

Understanding Supplier Types of Rigging Equipment

In the world of construction, manufacturing, and heavy lifting, rigging equipment plays a crucial role. Rigging refers to the process of using ropes, chains, or other means to lift and move heavy objects. The effectiveness and safety of this process heavily rely on the types of rigging equipment used, which can significantly vary among suppliers. Understanding the different supplier types of rigging equipment is essential for any business engaged in these industries, as it helps ensure that the materials and tools used meet specific performance and safety standards.

1. Manufacturers of Rigging Equipment

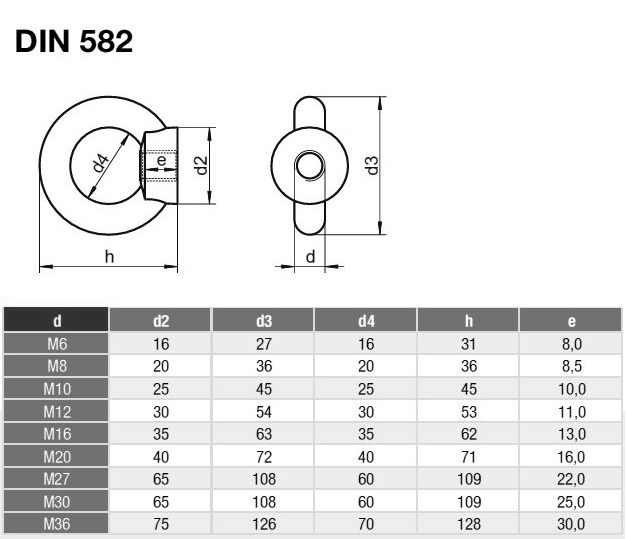

The first category of suppliers is the manufacturers themselves. These companies design and produce various types of rigging equipment, including slings, shackles, pulleys, and hoists. Manufacturers are often equipped with advanced technologies and quality control standards that can assure customers of the durability and reliability of the products. Additionally, they may provide bespoke solutions to meet unique lifting and rigging needs, allowing for customized lengths, materials, and configurations based on the user's requirements.

2. Distributors and Wholesalers

Another key player in the rigging equipment supply chain is distributors and wholesalers. These entities typically source rigging equipment from various manufacturers and sell it to end-users or retailers. They often carry a wide range of products, making them a convenient go-to source for customers looking for different types of rigging equipment. Distributors may also provide additional services such as educational resources, compliance information, and equipment maintenance support, ensuring that their clients make informed decisions regarding their rigging needs.

3. Rental Services

supplier types of rigging equipment

In many industries, purchasing rigging equipment may not always be feasible due to high costs or specific project requirements. This has led to the rise of rental services, which offer a cost-effective solution for businesses needing rigging equipment temporarily. Rental companies provide a variety of rigging equipment for short-term use, allowing companies to save on capital costs while still gaining access to high-quality gear. These services can enhance flexibility and adaptability, especially in projects that may require different equipment as they evolve.

4. Specialty Suppliers

Some suppliers focus on specialized rigging equipment tailored for specific industries. For example, marine rigging suppliers provide equipment designed specifically for maritime applications, such as ship lifting and cargo handling. Similarly, aerospace rigging suppliers offer unique solutions for lifting and transporting aircraft components. These specialty suppliers possess deep industry knowledge and can provide insights into the best practices, materials, and technologies that can significantly enhance the safety and efficacy of rigging operations within their respective fields.

5. Online Retailers

The emergence of e-commerce has transformed the way businesses procure rigging equipment. Online retailers offer the convenience of browsing vast catalogs of rigging supplies from the comfort of one's office or home. Customers can easily compare prices, read reviews, and find the exact items they need. While online shopping offers convenience, it’s essential to choose reputable vendors who provide high-quality products and reliable customer service to ensure that the equipment purchased meets necessary safety standards.

Conclusion

The supply landscape for rigging equipment is multifaceted, comprising various types of suppliers including manufacturers, distributors, rental services, specialty suppliers, and online retailers. Each category serves a unique purpose and caters to different customer needs within the rigging and lifting industry. Businesses must navigate this landscape carefully based on their specific requirements, considering factors such as quality, safety, and cost-effectiveness. By understanding the various supplier types, companies can make informed decisions when selecting rigging equipment, ultimately contributing to successful operations and enhanced workplace safety. As the industry continues to evolve, remaining aware of new trends and suppliers will be crucial for adapting to changing demands and innovations in rigging technology.