News

ನವೆಂ . 13, 2024 14:36 Back to list

custom rigging turnbuckles supply factories

Custom Rigging Turnbuckles Supply Factories and Their Importance

In the world of rigging and structural support, turnbuckles play a vital role in ensuring stability and tension regulation in various applications. Custom rigging turnbuckles, designed to meet specific requirements, are increasingly in demand across different industries, including construction, marine, and entertainment. As a result, supply factories specializing in the production of these custom turnbuckles have emerged as critical players in the manufacturing landscape.

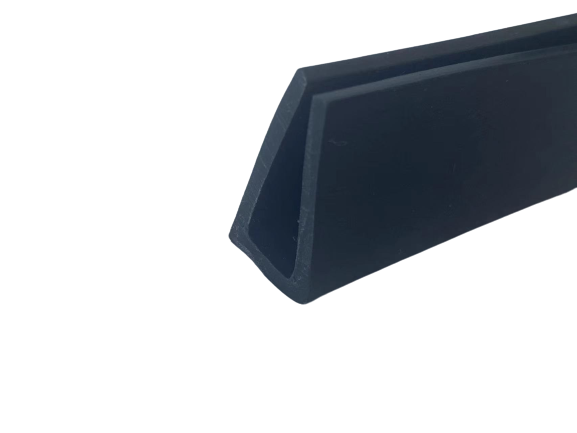

Custom rigging turnbuckles are versatile components that consist of a frame with threaded ends and are used to adjust the tension in ropes, cables, or rods. Their design allows for precision adjustments, which is essential in situations where load values must be optimized. Whether in scaffolding arrangements, suspension bridge support, or theatrical rigging, these specialized tools provide the necessary adaptability and strength.

The importance of supply factories that focus on custom rigging turnbuckles cannot be overstated. These factories employ skilled engineers and craftsmen who understand the nuances of rigging requirements. By leveraging advanced manufacturing techniques and high-quality materials, they can produce turnbuckles that meet stringent industry standards. Moreover, the ability to customize these components allows businesses to tailor solutions to their specific projects, ensuring both safety and efficiency.

custom rigging turnbuckles supply factories

One of the primary advantages of sourcing custom turnbuckles from dedicated supply factories is the quality assurance that comes with it. Factories can implement rigorous quality control processes, from material selection to final product testing. This attention to detail minimizes the risk of failure in critical applications, safeguarding both the equipment and the personnel involved.

Additionally, custom supply factories often offer a range of options regarding size, material, and finish. This flexibility ensures that clients can find turnbuckles that match their exact specifications, whether they require stainless steel for corrosion resistance in marine environments or aluminum for lightweight applications. Furthermore, engaging with supply factories can expedite the production process, allowing for quicker turnaround times on urgent projects.

In an era where efficiency and reliability are paramount, the significance of custom rigging turnbuckles and their supply factories becomes even more apparent. These industries are driven by innovation, continually seeking ways to enhance their offerings. With advancements in technology, factories can now incorporate smart design features into turnbuckles, such as load sensors, to provide real-time feedback on tension levels.

In conclusion, custom rigging turnbuckles are indispensable components in various applications, and the factories that supply them play a crucial role in ensuring their quality and reliability. As industries evolve and the demand for specialized equipment increases, these supply factories will continue to be essential partners in achieving safety and performance in rigging operations. By prioritizing quality and customization, businesses can better meet the challenges of their respective fields, enabling them to thrive in a competitive landscape.