News

កុម្ភៈ . 20, 2025 01:29 Back to list

wholesale eye bolt capacity

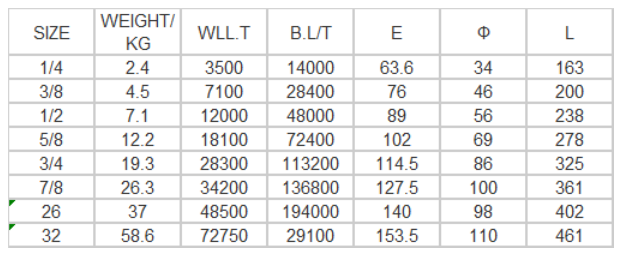

In the realm of construction and engineering, the importance of using high-quality eye bolts cannot be overstated. Commonly used to secure objects and carry significant loads, understanding the wholesale eye bolt capacity is fundamental. This comprehensive guide delves into insights, ensuring you make informed decisions in wholesale buying and application.

Ensuring trustworthiness in wholesale transactions involves verifying suppliers’ certifications and past performance. Reputable manufacturers should provide traceable material certificates and regular batch testing results, offering transparency from production to delivery. Engaging directly with manufacturers enables businesses to secure personalized advice and technical support, reinforcing trust and fostering long-term partnerships. Specialized software solutions and simulation technology are also augmenting the capabilities of engineers and procurement specialists. Simulations can pre-emptively identify potential stresses and weaknesses, enhancing decision-making processes and financial efficiency. Experts recommend utilizing 3D CAD software for precise modeling, helping predict real-world performance and optimal use scenarios. Case studies reveal the transformational impact of using quality-assured eye bolts. For instance, a major bridge construction project revamped its procurement strategy, prioritizing verified eye bolt capacities. This transition not only upheld safety standards but also reduced maintenance costs over time, illustrating the far-reaching benefits of meticulous selection criteria in wholesale purchases. Finally, with an emphasis on sustainability, the industry trend toward eco-friendly practices is gathering momentum. Leading suppliers are adopting greener manufacturing processes, such as using recycled materials and minimizing waste, aligning with global eco-conscious drives. Buyers mindful of environmental footprints find these initiatives appealing, adding a layer of corporate responsibility to their procurement goals. In conclusion, understanding the wholesale eye bolt capacity extends beyond mere numbers. It encompasses a nuanced appreciation of materials, engineering standards, practical applications, and ethical sourcing. As an industry professional, evaluating these interconnected aspects fortifies your decision-making, ensuring reliability, safety, and sustainability in every project embarked upon.

Ensuring trustworthiness in wholesale transactions involves verifying suppliers’ certifications and past performance. Reputable manufacturers should provide traceable material certificates and regular batch testing results, offering transparency from production to delivery. Engaging directly with manufacturers enables businesses to secure personalized advice and technical support, reinforcing trust and fostering long-term partnerships. Specialized software solutions and simulation technology are also augmenting the capabilities of engineers and procurement specialists. Simulations can pre-emptively identify potential stresses and weaknesses, enhancing decision-making processes and financial efficiency. Experts recommend utilizing 3D CAD software for precise modeling, helping predict real-world performance and optimal use scenarios. Case studies reveal the transformational impact of using quality-assured eye bolts. For instance, a major bridge construction project revamped its procurement strategy, prioritizing verified eye bolt capacities. This transition not only upheld safety standards but also reduced maintenance costs over time, illustrating the far-reaching benefits of meticulous selection criteria in wholesale purchases. Finally, with an emphasis on sustainability, the industry trend toward eco-friendly practices is gathering momentum. Leading suppliers are adopting greener manufacturing processes, such as using recycled materials and minimizing waste, aligning with global eco-conscious drives. Buyers mindful of environmental footprints find these initiatives appealing, adding a layer of corporate responsibility to their procurement goals. In conclusion, understanding the wholesale eye bolt capacity extends beyond mere numbers. It encompasses a nuanced appreciation of materials, engineering standards, practical applications, and ethical sourcing. As an industry professional, evaluating these interconnected aspects fortifies your decision-making, ensuring reliability, safety, and sustainability in every project embarked upon.

Share

Next: